Latest Electricity News - Overhead T&D

ATCO Electric agrees to $31 million penalty following regulator's investigation

ATCO Electric administrative penalty underscores an Alberta Utilities Commission probe into a sole-sourced First Nation contract, Jasper transmission line overpayments, and nondisclosure to ratepayers, sparked by a whistleblower and pending settlement approval.

Key Points

A $31M AUC settlement over alleged overpayment, sole-sourcing, and nondisclosure tied to a Jasper transmission line.

✅ $31M administrative penalty; AUC settlement pending approval

✅ Sole-sourced First Nation contract to protect related ATCO deal

✅ Overpayment concealed when seeking recovery from ratepayers

Regulated Alberta utility ATCO Electric has agreed to pay a $31 million administrative penalty after an Alberta Utilities Commission utilities watchdog investigation found it deliberately overpaid a First Nation group for work on a new transmission line, and then failed to disclose the reasons for it when it applied to be reimbursed by ratepayers for the extra cost.

An agreed statement of facts contained in a settlement agreement between ATCO Electric Ltd. and the commission's enforcement staff says the company sole-sourced a contract in 2018 for work that was necessary for an electric transmission line to Jasper, Alta., even as BC Hydro marked a Site C transmission line milestone elsewhere.

The company that won the contract was co-owned by the Simpcw First Nation in Barriere, B.C., while debates over a First Nations electricity line in Ontario underscore related issues, and the agreement says one of the reasons for the sole-sourcing was that another of Calgary-based ATCO's subsidiaries had a prior deal with the First Nation for infrastructure projects that included the provision of work camps on the Trans Mountain Pipeline expansion project.

The statement of facts says ATCO Electric feared that if it didn't grant the contract to the First Nation group and instead put the work to tender, amid legal pressures such as a treaty rights challenge, the group might back out of its deal with ATCO Structures and Logistics and partner with another, non-ATCO company on the Trans Mountain work.

The agreed statement says ATCO Electric paid several million dollars more than market value for some of the Jasper line work, while a Manitoba-Minnesota line delay was being weighed in another jurisdiction, and staff attempted to conceal the reasons for the overpayment when they sought to recover the extra money from Alberta consumers.

It states the investigation was sparked by a whistleblower, and notes the agreement between the utility commission's enforcement staff and ATCO Electric must still be approved by the Alberta Utilities Commission, a process comparable to hearings that consider oral traditional evidence on interprovincial lines.

The commission must be satisfied the settlement is in the public interest, a consideration often informed by concerns from Site C opponents in other regions.

Related News

Sign Up for Electricity Forum’s News Service

Weekly updates from our FREE News Service—get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

BC Hydro completes major milestone on Site C transmission line work

Site C 500 kV transmission lines strengthen the BC Hydro grid, linking the new substation and Peace Canyon via a 75 kilometre right-of-way to deliver clean energy, with 400 towers built and both circuits energized.

Key Points

High-voltage lines connecting Site C substation to the BC Hydro grid, delivering clean energy via Peace Canyon.

✅ Two 75 km circuits between Site C and Peace Canyon

✅ Connect new 500 kV substation to BC Hydro grid

✅ Over 400 towers built along existing right-of-way

The second and final 500 kilovolt, 75 kilometre transmission line on the Site C project, which has faced stability questions in recent years, has been completed and energized.

With this milestone, the work to connect the new Site C substation to the BC Hydro grid, amid treaty rights litigation that has at times shaped schedules, is complete. Once the Site C project begins generating electricity, much like when the Maritime Link first power flowed between Newfoundland and Nova Scotia, the transmission lines will help deliver clean energy to the rest of the province.

The two 75 kilometre transmission lines run along an existing right-of-way between Site C and the Peace Canyon generating station, a route that has seen community concerns from some northerners. The project’s first 500 kilovolt, 75 kilometre transmission line – along with the Site C substation – were both completed and energized in the fall of 2020.

BC Hydro awarded the Site C transmission line construction contract to Allteck Line Contractors Inc. (now Allteck Limited Partnership) in 2018. Since construction started on this part of the project in summer 2018, crews have built more than 400 towers and strung lines, even as other interties like the Manitoba-Minnesota line have faced scheduling uncertainty, over a total of 150 kilometres.

The two transmission lines are a major component of the Site C project, comparable to initiatives such as the New England Clean Power Link in scale, which also consists of the new 500 kilovolt substation and expanding the existing Peace Canyon 500 kilovolt gas-insulated switchgear to incorporate the two new 500 kilovolt transmission line terminals.

Work to complete three other 500 kilovolt transmission lines that will span one kilometre between the Site C generating station and Site C substation, similar to milestones on the Maritime Link project, is still underway. This work is expected to be complete in 2023.

Related News

Almost 500-mile-long lightning bolt crossed three US states

Longest Lightning Flash Record confirmed by WMO: a 477.2-mile megaflash spanning Mississippi, Louisiana, and Texas, detected by satellite sensors, highlighting Great Plains supercell storms, lightning safety, and extreme weather monitoring advancements.

Key Points

It is the WMO-verified 477.2-mile megaflash across MS, LA, and TX, detected via satellites.

✅ Spanned 477.2 miles across Mississippi, Louisiana, and Texas

✅ Verified by WMO using space-based lightning detection

✅ Occurs in megaflash-prone regions like the U.S. Great Plains

An almost 500-mile long bolt of lightning that lit up the sky across three US states has set a new world record for longest flash, scientists have confirmed.

The lightning bolt, extended a total of 477.2 miles (768 km) and spread across Mississippi, Louisiana, and Texas.

The previous record was 440.6 miles (709 km) and recorded in Brazil in 2018.

Lightning rarely extends over 10 miles and usually lasts under a second, yet utilities plan for severe weather when building long-distance lines such as the TransWest Express transmission project to enhance reliability.

Another lightning flash recorded in 2020 - in Uruguay and Argentina - has also set a new record for duration at 17.1 seconds. The previous record was 16.7 seconds.

"These are extraordinary records from lightning flash events," Professor Randall Cerveny, the WMO's rapporteur of weather and climate extremes, said.

According to the WMO, both records took place in areas prone to intense storms that produce 'megaflashes', namely the Great Plains region of the United States and the La Plata basin of South America's southern cone, where utilities adapting to climate change is an increasing priority.

Professor Cerveny added that greater extremes are likely to exist and are likely to be recorded in the future thanks to advances in space-based lightning detection technology.

The WMO warned that lightning was a hazard and urged people in both regions and around the world to take caution during storms, which can lead to extensive disruptions like the Tennessee power outages reported after severe weather.

"These extremely large and long-duration lightning events were not isolated but happened during active thunderstorms," lightning specialist Ron Holle said in a WMO statement.

"Any time there is thunder heard, it is time to reach a lightning-safe place".

Previously accepted WMO 'lightning extremes' include a 1975 incident in which 21 people were killed by a single flash of a lightning as they huddled inside a tent in Zimbabwe, and modern events show how dangerous weather can also cut electricity for days, as with the Hong Kong typhoon outages that affected families.

In another incident, 469 people were killed when lightning struck the Egyptian town of Dronka in 1994, causing burning oil to flood the town, and major incidents can also disrupt infrastructure, as seen during the LA power outage following a substation fire.

The WMO notes that the only lightning-safe locations are "substantial" buildings with wiring and plumbing, and dedicated lightning protection training helps reinforce these guidelines, rather than structures such as bus stops or those found at beaches.

Fully enclosed metal-topped vehicles are also considered reliably safe, and regional storm safety tips offer additional guidance.

Related News

Failed PG&E power line blamed for Drum fire off Hwy 246 last June

PG&E Drum Fire Cause identified as a power line failure in Santa Barbara County, with arcing electricity igniting vegetation near Buellton on Drum Canyon Road; 696 acres burned as investigators and CPUC review PG&E safety.

Key Points

A failed PG&E power line sparked the 696-acre Drum Fire near Buellton; the utility is conducting its own probe.

✅ Power line failed between poles, arcing ignited vegetation.

✅ 696 acres burned; no structures damaged or injuries.

✅ PG&E filed CPUC incident report; ongoing investigation.

A downed Pacific Gas and Electric Co. power line was the cause of the Drum fire that broke out June 14 on Drum Canyon Road northwest of Buellton, a reminder that a transformer explosion can also spark multiple fires, the Santa Barbara County Fire Department announced Thursday.

The fire broke out about 12:50 p.m. north of Highway 246 and burned about 696 acres of wildland before firefighters brought it under control, although no structures were damaged or mass outages like the Los Angeles power outage occurred, according to an incident summary.

A team of investigators pinpointed the official cause as a power line that failed between two utility poles and fell to the ground, and as downed line safety tips emphasize, arcing electricity ignited the surrounding vegetation, said County Fire Department spokesman Capt. Daniel Bertucelli.

In response, a PG&E spokesman said the utility is conducting its own investigation and does not have access to whatever data investigators used, and, as the ATCO regulatory penalty illustrates, such matters can draw significant oversight, but he noted the company filed an electric incident report on the wire with the California Public Utilities Commission on June 14.

"We are grateful to the first responders who fought the 2020 Drum fire in Santa Barbara County and helped make sure that there were no injuries or fatalities, outcomes not always seen in copper theft incidents, and no reports of structures damaged or burned," PG&E spokesman Mark Mesesan said.

"While we are continuing to conduct our own investigation into the events that led to the Drum fire, and as the Site C watchdog inquiry shows, oversight bodies can seek more transparency, PG&E does not have access to the Santa Barbara County Fire Department's report."

He said PG&E remains focused on reducing wildfire risk across its service area while limiting the scope and duration of public safety power shutoffs, including strategies like line-burying decisions adopted by other utilities, and that the safety of customers and communities it serves are its most important responsibility.

Related News

When did BC Hydro really know about Site C dam stability issues? Utilities watchdog wants to know

BC Utilities Commission Site C Dam Questions press BC Hydro on geotechnical risks, stability issues, cost overruns, oversight gaps, seeking transparency for ratepayers and clarity on contracts, mitigation, and the powerhouse and spillway foundations.

Key Points

Inquiry seeking explanations from BC Hydro on geotechnical risks, costs, timelines and oversight for Site C.

✅ Timeline of studies, monitoring, and mitigation actions

✅ Rationale for contracts, costs, and right bank construction

✅ Implications for ratepayers, oversight, and project stability

The watchdog B.C. Utilities Commission has sent BC Hydro 70 questions about the troubled Site C dam, asking when geotechnical risks were first identified and when the project’s assurance board was first made aware of potential issues related to the dam’s stability.

“I think they’ve come to the conclusion — but they don’t say it — that there’s been a cover-up by BC Hydro and by the government of British Columbia,” former BC Hydro CEO Marc Eliesen told The Narwhal.

On Oct. 21, The Narwhal reported that two top B.C. civil servants, including the senior bureaucrat who prepares Site C dam documents for cabinet, knew in May 2019 that the project faced serious geotechnical problems due to its “weak foundation” and the stability of the dam was “a significant risk.”

Get The Narwhal in your inbox!

People always tell us they love our newsletter. Find out yourself with a weekly dose of our ad‑free, independent journalism

“They [the civil servants] would have reported to their ministers and to the government in general,” said Eliesen, who is among 18 prominent Canadians calling for a halt to Site C work until an independent team of experts can determine if the geotechnical problems can be resolved and at what cost.

“It’s disingenuous for Premier [John] Horgan to try to suggest, ‘Well, I just found out about it recently.’ If that’s the case, he should fire the public servants who are representing the province.”

The public only found out about significant issues with the Site C dam at the end of July, when BC Hydro released overdue reports saying the project faces unknown cost overruns, schedule delays and, even as it achieved a transmission line milestone earlier, such profound geotechnical troubles that its overall health is classified as ‘red,’ meaning it is in serious trouble.

“The geotechnical challenges have been there all these years.”

The Site C dam is the largest publicly funded infrastructure project in B.C.’s history. If completed, it will flood 128 kilometres of the Peace River and its tributaries, forcing families from their homes and destroying Indigenous gravesites, hundreds of protected archeological sites, some of Canada’s best farmland and habitat for more than 100 species vulnerable to extinction.

Eliesen said geotechnical risks were a key reason BC Hydro’s board of directors rejected the project in the early 1990s, when he was at the helm of BC Hydro.

“The geotechnical challenges have been there all these years,” said Eliesen, who is also the former Chair and CEO of Ontario Hydro, where Ontario First Nations have urged intervention on a critical electricity line, the former Chair of Manitoba Hydro and the former Chair and CEO of the Manitoba Energy Authority.

Elsewhere, a Manitoba Hydro line to Minnesota has faced potential delays, highlighting broader grid planning challenges.

The B.C. Utilities Commission is an independent watchdog that makes sure ratepayers — including BC Hydro customers — receive safe and reliable energy services, as utilities adapt to climate change risks, “at fair rates.”

The commission’s questions to BC Hydro include 14 about the “foundational enhancements” BC Hydro now says are necessary to shore up the Site C dam, powerhouse and spillways.

The commission is asking BC Hydro to provide a timeline and overview of all geotechnical engineering studies and monitoring activities for the powerhouse, spillway and dam core areas, and to explain what specific risk management and mitigation practices were put into effect once risks were identified.

The commission also wants to know why construction activities continued on the right bank of the Peace River, where the powerhouse would be located, “after geotechnical risks materialized.”

It’s asking if geotechnical risks played a role in BC Hydro’s decision in March “to suspend or not resume work” on any components of the generating station and spillways.

The commission also wants BC Hydro to provide an itemized breakdown of a $690 million increase in the main civil works contract — held by Spain’s Acciona S.A. and the South Korean multinational conglomerate Samsung C&T Corp. — and to explain the rationale for awarding a no-bid contract to an unnamed First Nation and if other parties were made aware of that contract.

Peace River Jewels of the Peace Site C The Narwhal

Islands in the Peace River, known as the ‘jewels of the Peace’ will be destroyed for fill for the Site C dam or will be submerged underwater by the dam’s reservoir, a loss that opponents are sharing with northerners in community discussions. Photo: Byron Dueck

B.C. Utilities Commission chair and CEO David Morton said it’s not the first time the commission has requested additional information after receiving BC Hydro’s quarterly progress reports on the Site C dam.

“Our staff reads them to make sure they understand them and if there’s anything in then that’s not clear we go then we do go through this, we call it the IR — information request — process,” Morton said in an interview.

“There are things reported in here that we felt required a little more clarity, and we needed a little more understanding of them, so that’s why we asked the questions.”

The questions were sent to BC Hydro on Oct. 23, the day before the provincial election, but Morton said the commission is extraordinarily busy this year and that’s just a coincidence.

“Our resources are fairly strained. It would have been nice if it could have been done faster, it would be nice if everything could be done faster.”

“These questions are not politically motivated,” Morton said. “They’re not political questions. There’s no reason not to issue them when they’re ready.”

The commission has asked BC Hydro to respond by Nov. 19.

Read more: Top B.C. government officials knew Site C dam was in serious trouble over a year ago: FOI docs

Morton said the independent commission’s jurisdiction is limited because the B.C. government removed it from oversight of the project.

The commission, which would normally determine if a large dam like the Site C project is in the public’s financial interest, first examined BC Hydro’s proposal to build the dam in the early 1980s.

After almost two years of hearings, including testimony under oath, the commission concluded B.C. did not need the electricity. It found the Site C dam would have negative social and environmental impacts and said geothermal power should be investigated to meet future energy needs.

The project was revived in 2010 by the BC Liberal government, which touted energy from the Site C dam as a potential source of electricity for California and a way to supply B.C.’s future LNG industry with cheap power.

Not willing to countenance another rejection from the utilities commission, the government changed the law, stripping the commission of oversight for the project. The NDP government, which came to power in 2017, chose not to restore that oversight.

“The approval of the project was exempt from our oversight,” Morton said. “We can’t come along and say ‘there’s something we don’t like about what you’re doing, we’re going to stop construction.’ We’re not in that position and that’s not the focus of these questions.”

But the commission still retains oversight for the cost of construction once the project is complete, Morton said.

“The cost of construction has to be recovered in [hydro] rates. That means BC Hydro will need our approval to recover their construction cost in rates, and those are not insignificant amounts, more than $10.7 billion, in all likelihood.”

In order to recover the cost from ratepayers, the commission needs to be satisfied BC Hydro didn’t spend more money than necessary on the project, Morton said.

“As you can imagine, that’s not a straight forward review to do after the fact, after a 10-year construction project or whatever it ends up being … so we’re using these quarterly reports as an opportunity to try to stay on top of it and to flag any areas where we think there may be areas we need to look into in the future.”

The price tag for the Site C dam was $10.7 billion before BC Hydro’s announcement at the end of July — a leap from $6.6 billion when the project was first announced in 2010 and $8.8 billion when construction began in 2015.

Eliesen said the utilities commission should have been asking tough questions about the Site C dam far earlier.

“They’ve been remiss in their due diligence activities … They should have been quicker in raising questions with BC Hydro, rather than allowing BC Hydro to be exceptionally late in submitting their reports.”

BC Hydro is late in filing another Site C quarterly report, covering the period from April 1 to June 30.

The quarterly reports provide the B.C. public with rare glimpses of a project that international hydro expert Harvey Elwin described as being more secretive than any hydro project he has encountered in five decades working on large dams around the world, including in China.

Read more: Site C dam secrecy ‘extraordinary’, international hydro construction expert tells court proceeding

Morton said the commission could have ordered regular reporting for the Site C project if it had its previous oversight capability.

“Then we would have had the ability to follow up and ultimately order any delinquent reports to be filed. In this circumstance, they are being filed voluntarily. They can file it as late as they choose. We don’t have any jurisdiction.”

In addition to the six dozen questions, the commission has also filed confidential questions with BC Hydro. Morton said confidential information could include things such as competitive bid information. “BC Hydro itself may be under a confidentiality agreement not to disclose it.”

With oversight, the commission would also have been able to drill down into specific project elements, Morton said.

“We would have wanted to ensure that the construction followed what was approved. BC Hydro wouldn’t have the ability to make significant changes to the design and nature of the project as they went along.”

BC Hydro has been criticized for changing the design of the Site C dam to an L-shape, which Eliesen said “has never been done anywhere in the world for an earthen dam.”

Morton said an empowered commission could have opted to hold a public hearing about the design change and engage its own technical consultants, as it did in 2017 when the new NDP government asked it to conduct a fast-tracked review of the project’s economics.

Construction Site C Dam

A recent report by a U.S. energy economist found cancelling the Site C dam project would save BC Hydro customers an initial $116 million a year, with increasing savings growing over time. Photo: Garth Lenz / The Narwhal

The commission’s final report found the dam could cost more than $12 billion, that BC Hydro had a historical pattern of overestimating energy demand and that the same amount of energy could be produced by a suite of renewables, including wind and proposed pumped storage such as the Meaford project, for $8.8 billion or less.

The NDP government, under pressure from construction trade unions, opted to continue the project, refusing to disclose key financial information related to its decision.

When the geotechnical problems were revealed in July, the government announced the appointment of former deputy finance minister Peter Milburn as a special Site C project advisor who will work with BC Hydro and the Site C project assurance board to examine the project and provide the government with independent advice.

Eliesen said BC Hydro and the B.C. government should never have allowed the recent diversion of the Peace River to take place given the tremendous geotechnical challenges the project faces and its unknown cost and schedule for completion.

“It’s a disgrace and scandalous,” he said. “You can halt the river diversion, but you’ve got another four or five years left in construction of the dam. What are you going to do about all the cement you’ve poured if you’ve got stability problems?”

He said it’s counter-productive to continue with advice “from the same people who have been wrong, wrong, wrong,” without calling in independent global experts to examine the geotechnical problems.

“If you stop construction, whether it takes three or six months, that’s the time that’s required in order to give yourself a comfort level. But continuing to do what you’ve been doing is not the right course. You should have to sit back.”

Eliesen said it reminded him of the Pete Seeger song Waist Deep in the Big Muddy, which tells the story of a captain ordering his troops to keep slogging through a river because they will soon be on dry ground. After the captain drowns, the troops turn around.

“It’s a reflection of the fact that if you don’t look at what’s new, you just keep on doing what you’ve been doing in the past and that, unfortunately, is what’s happening here in this province with this project.”

Related News

Lightning Protection Systems Training

Lightning Protection Systems Training delivers live, instructor-led guidance on grounding, surge protection, NEC considerations, and risk mitigation for cell towers, broadcast antennas, coaxial cabling, tower lighting systems, maintenance, and compliance.

Key Points

A live online course on grounding, surge protection, and NEC-based risk mitigation for wireless and broadcast sites.

✅ Grounding, bonding, and surge suppression best practices

✅ NEC context for towers, antennas, and coax systems

✅ Risk assessment, earthing design, and maintenance checks

The Electricity Forum has organized a Lightning Protection Systems Training Course this Fall, as part of a broader curriculum that includes VFD drive training for maintenance professionals. Our 12-Hour live online instructor-led course is focused at companies who own or maintain wireless communications and broadcast towers and their antennas.

September 24-25 , 2020 - 10:00 am - 4:30 pm ET

Lightning damage to equipment results in losses exceeding twenty-six billion dollars annually in North America, and nearly three times that worldwide with more than 150 strikes per second. Insurance payout resulting from lightning damage, accounts for approximately 6.5 per cent of all industrial, commercial and institutional property and casualty claims, and following storm safety tips can help reduce risk. Ironically, lightning damage to equipment can be all but totally prevented.

Special lightning protection systems prevent damage and are simple, very reliable, and inexpensive, particularly when compared to the cost of equipment repair and replacement, as well as the possible consequences of harm to personnel. However, methods for lightning special protection cannot be found in the code books, i.e.; Mational Electrical Code (NEC) such as NEC 250 grounding and bonding requirements that inform safe installations.

For reference, the industry looks to grounding guidelines that help prevent electrical disasters and improve lightning resilience.

In less than 20 years, cellular mobile towers have proliferated on every continent, and are perfect lightning targets! To a lesser extent, AM, FM, and TV towers have also sprouted, sometimes sharing with cell systems. Not only are the towers at lightning risk, but also the cellular, broadcast, and communications antennas mounted on them, a fact underscored by a record-setting lightning bolt spanning multiple states. At risk too, are the attached cell site equipment, radio transmitters, coaxial cables, and tower light systems.

This Lightning Protection Systems Training course provides a general review of protection schemes and their impact on various industries. Strategies for mitigating damage and improving overall equipment performance are discussed, and related electric motor testing training supports predictive maintenance initiatives across facilities.

Professionals responsible for critical infrastructure also benefit from substation maintenance training to strengthen reliability under severe weather conditions.

Complete Course Details Here:

https://electricityforum.com/electrical-training/lightning-protection-systems-training

Related News

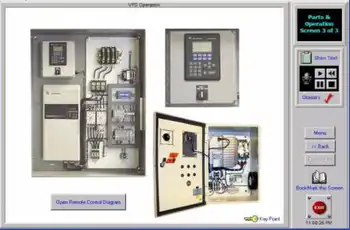

VFD Drive Training

VFD Training Courses deliver live, instructor-led guidance on variable frequency drives installation, commissioning, testing, maintenance, and troubleshooting across distribution systems, from PCC to motors, emphasizing grounding, harmonics mitigation, EMC, and best practices.

Key Points

Live, instructor-led VFD courses on installation, testing, maintenance, and safe operation in distribution systems.

✅ Live online, instructor-led with practical VFD commissioning steps

✅ Installation from PCC to motor: wiring, grounding, EMC, filters

✅ Troubleshooting VFD issues: harmonics, noise, overheating, faults

The Electricity Forum has organized a series of VFD Training Courses. Our 12- Hour live online instructor-led course covers the most important aspects related to the proper installation, commissioning, motor testing and maintenance and operation of Variable Frequency drives in the distribution system.

- September 17-18 , 2020 - 10:00 am - 4:30 pm ET

- November 9-10 , 2020 - 10:00 am - 4:30 pm ET

This course will highlight the proper installation of Variable Frequency Drives, including compliance with NEC 250 grounding and bonding requirements for safety. VFDs are being installed more frequently today; however there are still several installations with VFD Issues being ignored or incorrectly being addressed. Examples of improper installations will be discussed to indicate potential problems that can cause damaging consequences.

This course will provide an overview on the Distribution System from the Point of Common Coupling (Incoming Utility Power Connection Point), including large interconnections like the New England Clean Power Link project that influence system design, right down to the connection location of the motor(s). The student will be made aware of all the installation guidelines, including applicable grounding guidelines and best practices, needed to ensure a successful installation of VFDs.

As a special bonus, several technical papers and information on VFD operation and issues, including lightning protection systems considerations for facilities will be provided on a disc for the student to use as a reference source for covered course material.

All issues related to VFD and Motor installations will be presented with recommended solutions that align with substation maintenance training principles used across utilities. Students will work their way through a typical distribution system and discuss related issues or concerns, including electrical storm safety tips that inform field preparedness, at various points in the system.

Complete Course Details Here:

https://electricityforum.com/electrical-training/vfd-training

Related News

Substation Maintenance Training

Substation Maintenance Training delivers live online instruction on testing switchgear, circuit breakers, transformers, protective relays, batteries, and SCADA systems, covering safety procedures, condition assessment, predictive maintenance, and compliance for utility substations.

Key Points

A live online course on testing and maintaining substation switchgear, breakers, transformers, relays, and batteries.

✅ Live instructor-led, 12-hour web-based training

✅ Covers testing: insulation resistance, contact resistance, TLI

✅ Includes 7 days of post-course email mentoring

Our Substation Maintenance Training course is a 12-Hour Live online instruction-led course that will cover the maintenance and testing requirements for common substation facilities, and complements VFD drive training for professionals managing motor control systems.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Electrical Substation maintenance is a key component of any substation owner's electrical maintenance program. It has been well documented that failures in key procedures such as racking mechanisms, meters, relays and busses are among the most common source of unplanned outages. Electrical transmission, distribution and switching substations, as seen in BC Hydro's Site C transmission line work milestone, generally have switching, protection and control equipment and one or more transformers.Our electrical substation maintenance course focuses on maintenance and testing of switchgear, circuit breakers, batteries and protective relays.

This Substation Maintenance Training course will cover the maintenance and testing requirements for common substation devices, including power transformers, oil, air and vacuum circuit breakers, switchgear, ground grid systems aligned with NEC 250 grounding and bonding guidance, batteries, chargers and insulating liquids. This course focuses on what to do, when to do it and how to interpret the results from testing and maintenance. This Substation Maintenance course will deal with all of these important issues.

You Can Access The Live Online Training Through Our Web-Based Platform From Your Own Computer. You Can See And Hear The Instructor And See His Screen Live.

You Can Interact And Ask Questions, similar to our motor testing training sessions delivered online. The Cost Of The Training Also Includes 7 Days Of Email Mentoring With The Instructor.

LEARNING OBJECTIVES

- Substation Types, Applications, Components And lightning protection systems safety procedures

- Maintenance And Testing Methods For Medium-Voltage Circuit Breakers

- How To Perform Insulation Resistance, Contact Resistance On Air, Oil And Vacuum Breakers, And Tank Loss Index On Oil Circuit Breaker And Vacuum Bottle Integrity Tests On Vacuum Breaker

- Switchgear Arrangement, Torque Requirements, Insulation Systems, grounding guidelines And Maintenance Intervals

- How To Perform Switchgear Inspection And Maintenance

WHO SHOULD ATTEND

This course is designed for engineering project managers, engineers, and technicians from utilities who have built or are considering building or retrofitting substations or distribution systems with SCADA and substation integration and automation equipment, and for teams focused on electrical storm safety in the field.

Complete Course Details Here:

https://electricityforum.com/electrical-training/substation-maintenance-training

Related News

EF Partner Media

Related Articles From ET Magazine

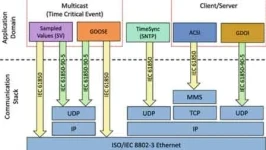

The Role of SCADA in Grid Monitoring and Control

As electric power systems grow in complexity, the need for real-time monitoring and control has never been greater. At the center of this transformation is SCADA—Supervisory Control and Data Acquisition—a system architecture that enables utilities to collect, process, and act on data from remote field devices. From high-voltage substations to distributed energy resources (DERs), SCADA platforms are the nerve center of modern grid operations.

SCADA systems provide utilities with critical operational visibility, allowing for effective grid management, improved reliability, and faster fault detection. As demand increases for automation, decentralized energy integration, and advanced analytics, SCADA’s role continues to expand well beyond its traditional boundaries.

SCADA Architecture: Core Components and Functions

The basic architecture of a SCADA system consists of three primary layers: field devices, communication infrastructure, and the central control system. Together, these layers enable seamless remote monitoring and control of electrical assets across wide geographic areas.

Field Devices: These include Remote Terminal Units

(RTUs) and Programmable Logic Controllers (PLCs) installed at substations, transformers, and switchgear. They interface with physical equipment and sensors to collect real-time data.

Communication Layer: Data is transmitted using telemetry protocols such as DNP3, Modbus, or IEC 60870-5-104 over Ethernet, fiber optics, or radio networks.

SCADA Control Center: A central Human-Machine Interface (HMI) displays data to operators and allows manual or automatic commands to be issued. This interface connects with historian databases, alarm systems, and control logic modules.

SCADA enables grid operators to supervise power flows, manage voltage levels, and respond to equipment failures in near real-time—essential capabilities for ensuring grid stability and minimizing downtime.

SCADA vs DMS vs EMS: Understanding the Differences

While SCADA forms the backbone of real-time operations, it’s often confused with other grid management systems like DMS (Distribution Management System) and EMS (Energy Management System). Each plays a distinct role in utility operations.

SCADA focuses on data acquisition and supervisory control. It provides real-time visibility into field equipment status and telemetry.

DMS builds on SCADA by adding distribution automation, outage management, volt/VAR control, and fault location isolation and service restoration (FLISR) capabilities. It is tailored for the medium- and low-voltage distribution grid.

EMS operates at the transmission level, optimizing power generation, load forecasting, unit commitment, and economic dispatch. EMS integrates market operations and power flow analysis into the control strategy.

In many utilities, these systems are integrated into a unified control platform to provide comprehensive situational awareness and efficient grid operations from generation to distribution.

Integrating DERs into SCADA Systems

As distributed energy resources (DERs)—such as rooftop solar, wind turbines, and battery storage—proliferate, SCADA systems must evolve to manage bi-directional power flows and maintain power quality.

Modern SCADA platforms are increasingly integrated with DER Management Systems (DERMS), enabling operators to:

- Monitor generation from behind-the-meter assets

- Control inverter settings for voltage regulation

- Coordinate dispatch with grid demands

- Ensure grid synchronization and stability

To achieve this, SCADA must support open protocols, real-time communication, and dynamic data modeling to accommodate the variability and intermittency of DERs. This shift is essential for grid modernization and the transition to a decentralized energy ecosystem.

Read the full article at:

https://online.electricity-today.com/electricity-today/q2-2025/

Cybersecurity in Substation and Grid Communications

As power systems become increasingly digitized and connected, the importance of cybersecurity in substation and grid communications has grown exponentially. With the integration of intelligent electronic devices (IEDs), SCADA systems, and remote monitoring, modern substations are now part of a broader cyber-physical infrastructure. While these technologies enable real-time control and improved reliability, they also expose utilities to cyber threats that can disrupt critical services and damage essential assets.

Ensuring the cybersecurity of substation networks is no longer optional—it’s a core requirement for grid stability, national security, and compliance with regulatory standards such as NERC CIP (North American Electric Reliability Corporation Critical Infrastructure Protection).

The Cyber Threat Landscape for Electric Utilities

Substations were once isolated, but the shift to remote access, IoT sensors, and cloud-connected platforms has expanded the attack surface dramatically. Today’s threats include malware, ransomware, insider threats, and state-sponsored attacks targeting the operational technology (OT) layer.

Because substations form the backbone of the transmission and distribution (T&D) network, any cyber incident can lead to blackouts, equipment failures, or cascading effects across the grid. Moreover, attackers often seek to exploit legacy devices, poor segmentation, or insecure remote connections to move laterally within the system.

NERC CIP Compliance: A Baseline for Protection

To address these growing risks, regulatory frameworks like NERC CIP have been developed to enforce a minimum standard of protection for critical infrastructure. NERC CIP governs the cybersecurity of bulk electric system assets across the U.S. and parts of Canada.

NERC CIP requires utilities to:

- Identify and categorize critical cyber assets

- Implement access control and authentication protocols

- Maintain audit trails and perform log analysis

- Conduct vulnerability assessments and incident response planning

Ensure physical and cyber perimeter security

Although NERC CIP provides a strong compliance foundation, it must be supplemented by real-time, adaptive defenses to address evolving threats and zero-day vulnerabilities.

Real-Time Threat Detection and Network Monitoring

Modern substations must go beyond static defenses and implement real-time threat detection capabilities. This includes the deployment of intrusion detection systems (IDS), network security monitoring (NSM) tools, and behavioral analytics platforms tailored for industrial control systems (ICS).

These tools enable operators to:

- Monitor communication patterns between IEDs, RTUs, and SCADA components

- Detect anomalies such as unexpected protocol usage or lateral movement

- Set automated alerts for known attack signatures or abnormal traffic volumes

- Analyze network flows in segmented OT zones

- Enhanced network visibility is critical, particularly when dealing with IEC 61850 protocols and other substation-specific communications that differ from traditional IT systems.

In addition, time-stamped logging, centralized SIEM integration, and forensic capabilities allow security teams to trace and respond to incidents rapidly, minimizing downtime and reducing impact.

Read the full article at:

https://online.electricity-today.com/electricity-today/q2-2025/

Understanding the IEC 61850 Protocol in Substation Automation

https://online.electricity-today.com/electricity-today/q2-2025/

Understanding the IEC 61850 Protocol in Substation Automation

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

EF T&D Live Online Forums

Register for our FREE T&D Live Online Forums and join our live expert-led webinars on the latest electrical industry topics.- Industry expert insights on trending technologies

- Free access to recorded webinar presentations

- Downloadable PDF presentations

- Convenient viewing on your schedule—no attendance required