Circuit Breaker Types Explained

By R.W. Hurst, Editor

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

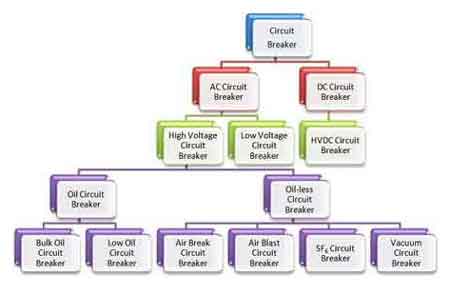

Circuit breaker types include air, vacuum, oil, and SF6 breakers, each designed for specific voltage levels and fault conditions. They protect electrical systems by interrupting current flow, ensuring safety, reliability, and efficient power distribution.

What are Circuit Breaker Types?

Circuit breaker types refer to classifications of breakers based on construction and application, ensuring system protection and fault interruption.

✅ Provides overcurrent and short-circuit protection

✅ Designed for low-, medium-, and high-voltage systems

✅ Ensures safety, reliability, and power system efficiency

Substation Relay Protection Training

Request a Free Training Quotation

Importance of CB Types

Understanding the various types of circuit breakers is crucial for ensuring safety and optimal system efficiency. Each type is designed to operate under specific voltage levels and environmental conditions, and choosing the wrong one can result in fires, equipment damage, or extended outages. By matching the right breaker to the right application, engineers and facility managers ensure protection, reliability, and compliance with standards.

Key benefits of selecting the correct breaker include:

-

Prevention of overloads and short circuits

-

Reduction of fire hazards and equipment failures

-

Improved coordination and fault-clearing performance

Voltage Classifications

Circuit breakers are categorized into voltage classes, which define their application and usage. Low-voltage devices are the most common in residential and commercial settings, while medium- and high-voltage designs provide essential protection in substations and transmission systems. Understanding these distinctions ensures that breakers are specified correctly for their operating environment.

-

Low-voltage (<1 kV): Miniature Circuit Breakers (MCB), Molded Case Circuit Breakers (MCCB), GFCI, AFCI, ELCB, and RCCB. Common in homes, offices, and the light industry.

-

Medium-voltage (1–72 kV): Air Circuit Breakers (ACB) and Vacuum Circuit Breakers (VCB), used in industrial switchgear and substations.

-

High-voltage (>72 kV): Oil and SF6 breakers, often integrated into air-insulated switchgear (AIS) or gas-insulated switchgear (GIS) for transmission networks.

Test Your Knowledge About Electrical Protection!

Think you know Electrical Protection? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Arc-Extinguishing Mechanisms

When a circuit breaker opens under fault conditions, an electrical arc forms that must be extinguished quickly and safely. Different breaker designs employ various arc-interruption techniques, each with its own advantages and trade-offs.

-

Air Circuit Breakers (ACB): Use pressurized air and arc chutes to cool and elongate the arc.

-

Vacuum Circuit Breakers (VCB): Extinguish arcs in sealed bottles where the absence of gas allows rapid dielectric recovery.

-

Oil Circuit Breakers: Rely on vaporized insulating oil that produces gases to cool and deionize the arc path.

-

SF6 Circuit Breakers: Utilize sulphur hexafluoride gas, which captures electrons and extinguishes arcs efficiently; however, environmental management is critical.

Common Circuit Breaker Types

Miniature circuit breakers (MCB) are used in residential and commercial circuits to protect branch wiring. Molded case circuit breakers (MCCB) extend protection to larger currents, often with adjustable trip units. GFCI and AFCI breakers improve residential safety by reducing shock and fire risks, while ELCB and RCCB protect against dangerous leakage currents. Magnetic and thermal breakers form the foundation of many designs by combining electromagnetic and thermal sensing for precise fault detection.

Standards and Ratings

Circuit breakers must meet rigorous standards to perform reliably under fault conditions. Global standards are set by IEC, IEEE, and UL, while national codes such as NEC and the Canadian Electrical Code define installation requirements. Breaker selection depends on ratings that define performance and coordination with other devices.

-

Rated current (In): Maximum continuous load current

-

Breaking capacity (Icu/Ics): Fault current interruption limit

-

Time-current curves: Define trip speed and selectivity with upstream/downstream devices

-

Trip units: Thermal-magnetic or electronic units, often adjustable for greater flexibility

Advantages and Limitations

Each breaker type carries distinct advantages and tradeoffs, influencing where it is most effectively applied.

| Type | Strengths | Weaknesses | Typical Applications |

|---|---|---|---|

| MCB | Compact, low cost, reliable | Limited capacity | Homes, offices |

| MCCB | Adjustable, handles higher loads | Bulkier, pricier | Industrial, commercial |

| ACB | Robust, reusable | Larger footprint | Switchboards, plants |

| VCB | Long service life, low maintenance | Higher initial cost | Medium-voltage substations |

| SF6 | High reliability, compact | Environmental issues | Transmission networks |

| Oil | Proven technology | Fire risk, heavy maintenance | Legacy HV systems |

Selection Guidelines

Proper selection requires evaluating more than just the current rating. Engineers must ensure breakers can handle the system’s operating conditions, coordinate properly with other devices, and remain cost-effective over their lifecycle.

-

Voltage level and available fault current

-

Current rating and trip unit type

-

Coordination with upstream/downstream devices

-

Environmental factors: enclosure, temperature, maintenance access

-

Lifecycle costs: spares, testing, modernization potential

Emerging and Specialized Types

As electrical systems evolve, new breaker designs are being introduced to improve safety and reliability. Automatic reclosers restore service after temporary faults in distribution networks. Disconnecting circuit breakers (DCB) integrate breaker and isolator functions. Solid-state breakers utilize semiconductors for ultra-fast switching, whereas smart breakers incorporate monitoring, diagnostics, and communication capabilities. Hybrid AFCI/GFCI devices combine dual protections in a single unit, enhancing safety in modern residential installations.

Maintenance and Lifecycle

Reliable performance depends on effective maintenance practices. Breakers should be inspected regularly for signs of contact wear, insulation condition, and proper mechanical operation. Testing methods such as secondary injection confirm trip unit accuracy, while thermal imaging and insulation resistance testing help identify hidden faults. Oil breakers require fluid analysis to detect aging, and SF6 breakers must be monitored for gas quality and leakage. Retrofit options, such as updated trip units or replacing older oil designs with vacuum technology, extend equipment life while improving safety and compliance.

Integration with Switchgear

Circuit breakers form part of larger switchgear assemblies that provide isolation, busbar connections, and coordination with protective relays. In low-voltage settings, breakers are installed in panels and switchboards, while medium- and high-voltage breakers are integrated into AIS or GIS systems for substations. Understanding this integration highlights their role not only as protective devices but also as critical elements in system reliability and grid stability.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Types of circuit breakers range from compact MCBs in homes to high-voltage SF6 breakers in transmission networks. By understanding their classifications, arc-interrupting methods, ratings, and applications, engineers and facility managers can select devices that strike a balance between safety, reliability, and sustainability. With innovations such as solid-state and smart breakers, the field continues to advance, offering more effective protection for modern electrical systems.

Related Articles