Latest Electrical Protection Articles

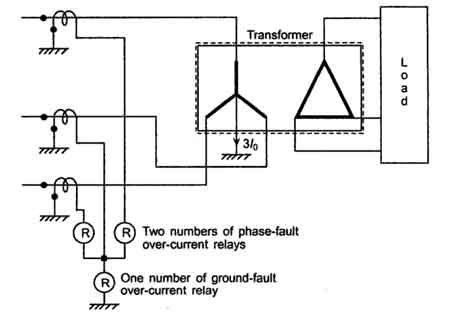

Ground Fault Protection

Ground fault protection detects leakage currents and interrupts power to prevent electric shock, equipment damage, and fire hazards. Using GFCIs, breakers, and relays ensures electrical safety and code compliance in industrial facilities.

What is Ground Fault Protection?

Ground fault protection is a safety principle built into electrical systems to protect both people and property from the hazards created when electricity escapes its intended path.

✅ Detects leakage currents to ground that standard overcurrent devices may miss

✅ Reduces the risk of electric shock, fires, and equipment damage

✅ Required by the NEC and CE Code in many commercial and industrial systems

When current leaves an energized conductor and flows to ground, the risk of shock, overheating, or fire increases dramatically. Protective devices sense this condition and trip the circuit before it becomes catastrophic.

Basic Protection Relay Training

Request a Free Training Quotation

Short-circuit protection addresses excessive current caused by faults between conductors, while ground-fault protection specifically targets dangerous leakage to ground. Both work together to provide a layered electrical safety system.

How Ground Fault Protection Works

Devices such as GFCIs, AFCIs, and earth leakage breakers monitor current flow and respond instantly to abnormal conditions. For example, a GFCI measures the balance between hot and neutral conductors—any imbalance signals a leakage to ground and triggers a trip. Similarly, fault current calculation and relay coordination studies help engineers establish the correct pickup points, ensuring that ground fault devices operate in harmony with upstream overcurrent protection.

To understand the function and importance of various fault response devices, refer to our guide on circuit protection devices, which includes fuses, relays, and breakers.

Understanding Common Fault Scenarios

A ground fault typically occurs when insulation is damaged or when a live conductor comes into contact with a grounded surface. The resulting low-resistance path can cause overheating and arcing. Ground fault protection devices such as GFCIs, RCDs, and ELCBs quickly detect these hazards. In larger facilities, the design of the grounding system is crucial to the operation of protective devices. Some industrial plants utilize high-resistance grounding to limit current during a fault, maintaining online operations while still detecting hazardous leakage. Where systems lack a neutral, earthing transformers are installed to establish a reference point for ground fault relays.

Ground Fault Circuit Interrupters (GFCIs)

GFCIs are the most common ground fault protection devices in residential and light commercial use. Required by the NEC in bathrooms, kitchens, garages, and outdoor areas, these devices trip the circuit within milliseconds if a leakage current as low as 4–6 mA is detected. Unlike overcurrent breakers, they respond to subtle, potentially fatal imbalances. See our detailed overview of GFCI protection for code applications and testing requirements.

AFCIs and ELCBs: Additional Protection Devices

Arc fault circuit interrupters (AFCIs) protect against fires caused by arcing faults. A ground fault protection device is especially important in bedrooms and living spaces where damaged cords or loose connections might ignite combustible materials. AFCI protection is now mandated in many parts of the NEC. Earth leakage circuit breakers (ELCBs), while less common in North America, are widely used internationally and function similarly to residual current devices. Understanding which device suits your system ensures layered safety across different applications.

NEC and CE Code Requirements

Both the U.S. National Electrical Code and the Canadian Electrical Code have expanded requirements for ground fault protection over time. For example, NEC 210.8 outlines residential GFCI locations, while NEC 230.95 requires ground fault protection on certain feeders. Articles such as NEC 250.122 and grounding and bonding and the NEC provide essential context for sizing conductors and maintaining an effective fault-current path. For a broader primer, see our pages on electrical grounding and the grounding electrode conductor.

Maintenance, Testing, and Troubleshooting

Like any safety system, ground fault protection requires regular testing and inspection. GFCI outlets should be tested monthly, and protective relays should be verified during scheduled maintenance. Problems such as nuisance tripping or undetected faults may stem from wiring errors, insulation breakdown, or malfunctioning devices. In industrial systems, engineers often rely on arc flash studies and available fault current calculations to confirm that ground fault devices operate correctly under worst-case conditions.

Ground fault protection is not just a code requirement—it is a life-saving measure. By detecting leakage currents, interrupting circuits before they cause harm, and complementing overcurrent and arc-fault protection, these systems provide a foundation for electrical safety. Whether in a home bathroom outlet or a large industrial power system, understanding and maintaining ground fault protection ensures people and property remain safe.

Related Articles

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

What Is A Fuse Explained

A fuse is a protective electrical device that prevents circuit overload, short circuits, and wiring faults by breaking the flow of fault current. It safeguards electrical systems, equipment, and wiring from damage caused by unintended electrical paths or excessive current.

What Is A Fuse?

A fuse is an electrical safety device that protects electrical circuits and electronic devices from damage caused by excessive current.

✅ A fuse is an electrical safety device designed to interrupt excessive current flow and protect circuits from damage.

✅ A fuse prevents hazards caused by overloads, short circuits, and wiring faults.

✅ Fuses ensure electrical systems operate safely by stopping fault current through a thin, sacrificial wire or element.

Power System Protection Courses

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

A fuse is a protective electrical safety device designed to interrupt excessive current and prevent damage to circuits, equipment, and wiring. By disconnecting the circuit when an overload, short circuit, or wiring fault occurs, it safeguards against fire hazards and equipment failure. This fuse protection is achieved through a thin element that melts when the current exceeds safe limits, cutting off the fault current before it spreads further. To understand how engineers maintain electrical system safety, explore our electrical protection channel, which covers essential devices and best practices.

A fuse is one of the simplest and most effective forms of circuit protection. It acts as a sacrificial component that interrupts electrical flow when current levels exceed the system’s capacity. Unlike a circuit breaker, which can be reset, a fuse must be replaced once it operates.

Key purposes of a fuse include:

-

Protecting wiring, devices, and people from dangerous overcurrent

-

Isolating faults quickly to prevent fire or equipment damage

-

Providing reliable, cost-effective safety in electrical systems

How a Fuse Works

These devices function by creating a controlled weak point in a circuit. When the current surpasses the rating, the fuse protective element melts, breaking the connection. Different applications require different responses: fast-acting fuse designs protect sensitive electronics, while time-delay types (slow-blow) allow temporary surges, such as those from motor start-ups, without shutting down the circuit.

Key operational fuse concepts include:

-

Time-current curves, which show how quickly a device reacts to varying levels of overcurrent

-

Selective coordination, ensuring only the faulty section of a system disconnects while the rest remains powered

-

Energy limitation, often described by I²t ratings, which measure the total energy let through during fault conditions

Fuse Ratings and Standards

Every fuse carries specific ratings that define its performance. The current rating shows how much current it can safely carry, while the voltage rating ensures it can interrupt circuits at the required level. Breaking capacity (or interrupting rating) is equally important, as it defines the maximum fault current the device can clear without failing.

To ensure safety and consistency, manufacturers comply with international standards:

-

IEC 60269, covering low-voltage fuse applications globally

-

UL 248, used widely across North America

-

Local electrical codes, which define installation and safety requirements in homes, businesses, and industry

One important safeguard against dangerous wiring faults is AFCI protection, which helps prevent electrical fires caused by arc faults. For a deeper insight, see our guide on arc fault circuit interrupter protection devices, which detect and stop arcing conditions.

Fuse Construction and Materials

The construction of fuses varies depending on use. The fusible link may be made of copper, silver, zinc, or alloys selected for predictable melting behavior. The body may be glass, ceramic, or molded plastic. Sand-filled designs improve arc quenching and safety at higher fault levels. These choices directly affect performance, durability, and inspection methods.

Types of Fuses

Different styles of fuses are designed for various environments. Cartridge types are commonly used in panels and appliances, while blade-style elements predominate in automotive systems. High-voltage fuses protect power transmission and distribution equipment.

Other notable types include:

-

Resettable PTC fuses, which recover automatically once the fault clears

-

Thermal links, which trigger in response to overheating in appliances

-

NH and expulsion fuse designs, used in industrial and utility distribution systems

-

Specialty components for semiconductors, solar arrays, and electronics

Fuses in Everyday Use

In household systems, a blown fuse is often the first sign of trouble, typically caused by overloaded circuits or faulty appliances. When this happens, the affected area loses power until the component is replaced.

Safe replacement practices include:

-

Always matching the fuse type and rating specified by the manufacturer or code

-

Turning off the power before removing or installing a new element

-

Investigating the cause of failure before restoring the circuit

-

Considering an upgrade from older fuse boxes to breaker panels for convenience and safety

Methods for assessing risks and planning protective measures. A solid understanding of fault current calculation is essential for designing effective short-circuit protection systems.

How Is a Fuse Different from a Circuit Breaker?

Both devices protect against overcurrent, but their operation and convenience differ. A fuse melts and disconnects permanently, while a circuit breaker trips a mechanical switch that can be reset. Different circuit breaker types are designed to protect against short circuits and overloads in specific applications.

Main differences include:

-

Function: a fuse relies on melting; a breaker uses an electromechanical trip

-

Reusability: fuses are single-use, breakers reset and reuse

-

Responsiveness: breakers typically react faster in modern systems

-

Flexibility: breakers offer adjustable ratings for different loads

-

Cost: fuses are cheaper initially; breakers save money over time

-

Size: fuses are smaller, while breakers are larger and panel-mounted

-

Indicators: breakers often include visual trip flags; fuses may require inspection

Industrial and Utility Fuse Applications

Beyond homes and small devices, fuses play a vital role in heavy industry and power distribution. High-voltage protection is critical in substations and transmission lines. NH fuses, expulsion fuses, and bayonet designs are widely used in these environments, offering robust fault-clearing capacity while meeting strict safety standards.

The fuse remains one of the most straightforward and dependable forms of overcurrent protection. By providing fast, automatic disconnection under fault conditions, they safeguard wiring, devices, and people from electrical hazards. While circuit breakers have become more common in modern installations, fuses continue to serve in automotive, industrial, and high-voltage applications worldwide. Choosing the right circuit protection device and understanding its ratings, standards, and construction are essential for maintaining safe and reliable electrical systems.

Related Articles

Maximum Fault Current Calculation Explained

Maximum fault current calculation quantifies short-circuit current using source impedance, transformer data, and conductor reactance for protective device coordination, equipment rating, arc flash studies, and IEC 60909 compliant fault level assessments.

What Is Maximum Fault Current Calculation?

Maximum fault current calculation estimates short-circuit current to size protective devices and verify ratings.

✅ Apply IEC 60909 or ANSI C37 short-circuit methods

✅ Include source, transformer, and line impedances

✅ Validate breaker kAIC, bus bracing, and arc-flash labels

Maximum Fault Current Calculation

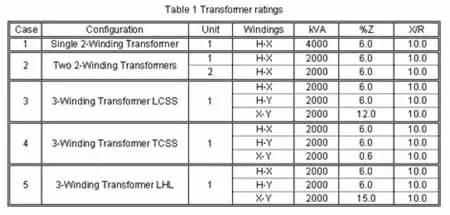

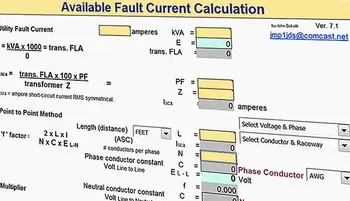

In order to determine maximum fault current in either a single-phase circuit or a three-phase circuit, you need to perform a calculation involving impedance. Total impedance is the sum of the impedances of the conductors from the origin of the installation to the circuit under consideration. For single phase circuits, the maximum fault current is between the phase and the neutral and in three-phase circuits the maximum fault current is when all phases are shorted (symmetrical current). The total impedance is that with operating temperature 20 degrees C (lower temperature means lower resistance).

For a concise refresher on definitions, see what is fault current to align terminology used here.

Power System Protection Courses

For broader context on relaying, coordination, and device schemes, consult power system protection as you plan your studies.

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

Maximum fault current calculations should be performed at all critical points in the system including:

- Service entrance equipment

- Transfer switches

- Panelboards

- Load centers

- Motor control centers

- Disconnects

- Motor starters

Normally, fault current studies involve calculating a bolted three-phase fault condition. This can be characterized as all three phases “bolted” together to create a zero impedance connection. This establishes a “worst case” (highest current) condition that results in maximum three- phase thermal and mechanical stress in the system.

To compare bolted faults with unsymmetrical events, review types of short-circuit faults to understand characteristic currents.

From this calculation, other fault condition types can be approximated. This “worst case” condition should be used for interrupting rating, component protection, “Table” method for determining PPE per NFPA 70E and selective coordination. In practice, quantifying available fault current at equipment line terminals informs PPE selection and device ratings.

Arc flash hazard analysis calculations should consider both maximum and minimum fault current calculations. Incident energy depends upon current and time. For lower arcing current values, clearing times could be longer than those for higher arcing current values, which could result in higher incident energy values. Therefore, an arc flash analysis must consider both spectrum of available fault current for calculating arcing currents, which are then compared with OCPD TCC curves to determine clearing times. Effective selection of TCCs starts with grasping overcurrent protection concepts that shape device behavior.

There are several variables in a distribution system affecting calculated bolted three-phase fault currents. Variable values applicable for the specific application analysis must be selected. The point-to-point method presented in this section includes several adjustment factors given in notes and footnotes that can be applied, and that will affect results. Some of the parameters that must be considered include utility source fault current, motor contribution, transformer percent impedance tolerance and voltage variance.

A step-by-step point-to-point example is summarized in fault current calculation to streamline hand calculations.

In most situations, the utility source(s) or on-site energy sources (such as generators) are the major fault current contributors. The point-to- point method includes steps and examples that assume an infinite available fault current from the utility source. Generally, this is a good assumption for highest, worst case conditions since the property owner has no control over the utility’s system and future utility changes. In many cases, a large increase in the utility available fault current does not increase the building system’s fault current a great deal on the secondary of the service transformer. However, there are cases where the actual utility medium voltage available fault current provides a more accurate fault current assessment (minimum bolted fault current conditions) that may be needed to assess arc flash hazards.

Coordinating primary and secondary devices should consider transformer protection practices to balance sensitivity and security.

When motors are in the system, motor fault current contribution is also a very important factor to include in any fault current analysis. When a fault occurs, motor contribution adds to the fault current magnitude, with running motors contributing four to six times their normal full load current. Series rated combinations can’t be used in specific situations due to motor fault current contributions.

For short time duration capacitor discharge currents, certain IEEE (Institute of Electrical and Electronic Engineers) publications detail how to calculate these currents if they are substantial.

Read Other Electrical System Protection Articles

Transformer Protection Explained

Related Articles

Load Break Switch Explained

A load break switch safely interrupts electrical circuits under load, ensuring reliable power distribution, fault protection, and operator safety. Common in medium-voltage switchgear, it enhances system reliability, supports grid efficiency, and meets utility standards.

What is a Load Break Switch?

Also known as a load interrupter switch, this critical component enables safe and efficient operation within power distribution systems.

✅ Interrupts electrical circuits under load conditions

✅ Enhances safety in medium-voltage distribution networks

✅ Improves reliability and fault protection in switchgear systems

Understanding the different types, applications, and safety considerations associated with these devices is crucial for electrical professionals working with medium-voltage equipment.

Request a Free Electrical Protection Training Quotation

A load break switch plays a vital role in power system safety, complementing other circuit protection devices used in electrical distribution networks.

In medium-voltage distribution systems, this interrupter works in conjunction with switchgear and other circuit protection devices to provide safe disconnection under load. Variants include cost-effective air break switches for overhead lines, gas-insulated types for superior arc-quenching, and vacuum interrupter models for indoor or space-constrained applications. These configurations enhance fault isolation, operator safety, and grid flexibility by allowing maintenance without shutting down the entire system. Integrated with protective relays, fuses, and breakers, they reduce downtime and bolster overall power system protection.

Types of Load Break Switches

A load break switch comes in several forms suited to different voltage classes and environments. Pole-mounted air break versions serve outdoor distribution, while enclosed interrupters protect against harsh conditions. SF₆-gas units and vacuum interrupters are utilized in higher-voltage setups for enhanced insulation and improved arc management. The selection depends on voltage, current rating, and environmental demands. Unlike a circuit breaker, which interrupts short-circuit faults, a load break switch is primarily designed for safe switching under load, ensuring reliable power system protection.

Applications

Load break switches are essential across power grids. In medium-voltage networks, they isolate segments for maintenance or fault response. In industrial settings, technicians use them to safely disconnect equipment. Substations deploy them to manage power flow between network zones. Technicians may also compare their use against fuse-switch units and current-limiting fuses to determine the optimal protection strategy. Electrical engineers often compare the function of a load break switch with fuse types and current limiting fuses to determine the best solution for distribution safety.

Advantages

The ability to make and break load under energized conditions reduces arc flash risks and maintenance interruptions. They offer a simpler, cost-effective alternative to circuit breakers for routine switching and support flexible network reconfiguration—ultimately improving operational efficiency and system resilience. Coupling with protective relays enhances fault detection and coordinated response within switchgear assemblies. In medium-voltage switchgear, the coordination between a load break switch and protective relays enhances fault detection and relay and circuit breaker coordination.

Installation and Maintenance

Proper setup involves secure mounting, conductor connections, and performance testing. Regular inspection of contacts, mechanisms, and insulation is vital, especially for air-insulated and SF₆ units. Following manufacturer and industry best practices ensures long-term serviceability and safety. Although devices like Arc Fault Circuit Interrupters and GFCIs handle specific hazards, the primary role of this switch remains safe load interruption and isolation. While devices like arc fault circuit interrupters and GFCI protection safeguard against specific hazards, the load break switch provides essential switching for maintenance and fault isolation.

Safety Considerations

Safety is paramount when working with energized systems. Trained operators should follow established procedures, don appropriate PPE, and use clear signage. Lockout/tagout protocols are crucial for preventing accidental re-energization during service.

Frequently Asked Questions

What is the purpose of a load break switch?

It enables safe circuit operation under load, allowing maintenance and network reconfiguration without shutdown.

What are the disadvantages of a load break switch?

It’s typically more costly than a standard disconnect switch and lacks the capacity to interrupt high fault currents.

How much current can a load break switch interrupt?

Ratings vary by type; consult the manufacturer's data. They’re not designed to interrupt short-circuit currents and usually require redundancy from protective devices. To calculate ratings for a load break switch, engineers often rely on fault current calculation and short circuit analysis to ensure compliance and safe operation.

Can a load break switch trip?

No, these switches are usually manually or remotely operated and do not have automatic trip functions. Understanding how a load interrupter switch integrates with switchgear and transformer protection systems is crucial for designing safe, efficient electrical distribution networks.

Related Articles

What is Protective Relay?

Protective relays detect electrical faults, trigger breakers, and isolate damaged circuits to ensure equipment protection, electrical safety, and reliable power system operation across industrial, commercial, and utility environments.

What is Protective Relay?

A protective relay is a monitoring device that senses abnormal electrical conditions and initiates breaker operation to prevent damage and hazards.

✅ Detects faults such as overloads, short circuits, and ground faults

✅ Coordinates with circuit breakers for timely isolation

✅ Ensures system safety, reliability, and equipment protection

Basic Protection Relay Training

Request a Free Training Quotation

It is a vital component in electrical power systems, designed to safeguard equipment and personnel from the damaging effects of abnormal conditions, such as short circuits, overcurrents, and insulation faults. These devices function as the first line of defence, continuously monitoring the electrical system for any irregularities.

When it detects an anomaly, it initiates a rapid response, typically by sending a signal to trip a circuit breaker. This action isolates the faulty section of the system, limiting the extent of damage and preventing cascading failures.

At its core, it serves as a vigilant monitor of electrical systems, continuously assessing conditions like current, voltage, and frequency. When these values deviate beyond acceptable thresholds, the relay working mechanism is activated. Protective devices such as these are crucial in high-voltage environments where the consequences of a fault can be catastrophic. Their role extends beyond simple detection; they act as decision-makers, determining the appropriate response to an issue and activating circuit breakers accordingly.

The evolution of electrical protection systems has seen a shift from traditional electromechanical devices to more advanced digital protective relays and numeric relay technologies. Unlike their mechanical predecessors, digital relays leverage sophisticated algorithms and microprocessor-based technology to analyze electrical data with speed and precision. This shift enables enhanced functionality, improved diagnostics, and more efficient fault isolation. Modern systems can also incorporate distance relay technology, which detects faults based on the impedance of a line, offering faster and more accurate protection for transmission lines.

Types of Protective Relays

There are several types of relays, each designed to address specific electrical faults. Overcurrent relays, for instance, respond to excessive current flow that may result from a short circuit or overload. Distance relays, as previously mentioned, measure the distance to a fault along transmission lines and act accordingly. Other types of relays include earth fault relays, which detect ground faults, and differential relays, which compare the incoming and outgoing current of a system to identify inconsistencies. Solid-state relays have also become a popular choice due to their reliability and ability to handle high-frequency signals.

Modern electrical protection systems frequently utilize digital protective relays, which provide enhanced capabilities compared to traditional electromechanical or solid-state relays. These digital devices can perform complex calculations and adapt to changing system conditions, providing more precise and reliable protection.

Components of a Protective Relay

The components of protective relay systems play a vital role in their operation. Key elements include current transformers (CTs) and voltage transformers (VTs), which provide the relay with scaled-down versions of the high voltage currents and voltages for analysis. The data from these transformers feeds into the relay’s logic, where calculations are made to determine if a fault is present. When an abnormal condition is detected, the relay’s tripping circuit is activated, sending a signal to trip a circuit breaker and isolate the faulted section of the network.

-

Current Transformers (CTs): These devices reduce the high current in the power system to a lower, measurable level.

-

Voltage Transformers (VTs): Similar to CTs, VTs reduce the high voltage in the system to a safer level.

-

Microprocessor: The microprocessor is the "brain" of the digital relay, processing information from the CTs and VTs and making decisions.

-

Output Circuits: These circuits transmit the trip signal to the circuit breaker.

Applications for protective relays span a broad range of industries and electrical systems. They are fundamental in power generation facilities, transmission lines, distribution networks, and industrial plants. Wherever electrical power is generated, transmitted, or distributed, protective relay systems are present to ensure the continuous and safe delivery of electricity. Transmission lines, in particular, benefit greatly from distance relay systems, as they provide precise fault location and rapid disconnection, minimizing downtime and protecting valuable infrastructure.

The benefits of using protection relays are that they ensure the overall reliability, safety, and efficiency of electrical systems. By isolating faults quickly, they reduce equipment damage and prevent extended outages. For instance, when an overcurrent relay identifies excessive current flow, it can activate the tripping mechanism before any significant damage occurs. This proactive approach minimizes repair costs and enhances system stability. Furthermore, the introduction of digital protective relays and numeric relay systems has improved the speed, accuracy, and diagnostic capabilities of these devices, resulting in better fault analysis and system recovery times.

The protective relay is indispensable to modern electrical power systems. Their ability to detect abnormal conditions, activate circuit breakers, and protect valuable equipment ensures the safe and efficient operation of high voltage networks. The advancement from electromechanical to digital protective relays has introduced faster, more precise protection methods, reducing downtime and equipment damage. With diverse applications across power generation, transmission, and distribution, protective relays remain a cornerstone of electrical system reliability and safety.

Frequently Asked Questions

What is the function of a protection relay?

The primary function of a protection relay is to detect abnormal conditions in an electrical system and respond accordingly to prevent damage to equipment and ensure the safety of personnel. It continuously monitors system parameters like current, voltage, and frequency. If these values deviate beyond predefined limits, the relay activates a tripping circuit to isolate the faulted section of the system by sending a signal to trip a circuit breaker.

Do protective relays trip circuit breakers?

Yes, protective relays trip circuit breakers. When a fault or abnormal condition is detected, the relay sends a signal to the circuit breaker’s tripping mechanism, causing it to open and disconnect the affected section of the electrical network. This process helps prevent the spread of electrical faults and minimizes equipment damage and downtime.

What is the difference between protection and relay?

Protection refers to the overall system or strategy designed to safeguard electrical networks from faults and other issues that could compromise system integrity. A relay, on the other hand, is a specific device within this protection system. While protection encompasses various components, including circuit breakers, transformers, and sensors, the relay’s role is to detect faults and signal the protective devices (like circuit breakers) to take action. In essence, protection is the goal, and relays are one of the tools used to achieve that goal.

Related Articles

Electric Motor Protection Explained

Electric motor protection ensures reliable operation by preventing overloads, short circuits, overheating, and arc flash hazards. It improves safety, extends equipment lifespan, and supports efficient industrial power systems.

What is Electric Motor Protection?

Electric motor protection refers to safety measures and devices that guard motors against electrical and mechanical faults, ensuring performance, reliability, and compliance.

✅ Involves the use of overload relays, circuit breakers, and thermal protection mechanisms

✅ Minimizes downtime, reduces repair costs, and safeguards personnel and infrastructure

✅ Commonly applied in factories, commercial buildings, and critical machinery installations

Basic Protection Relay Training

Request a Free Training Quotation

Understanding Electric Motor Protection

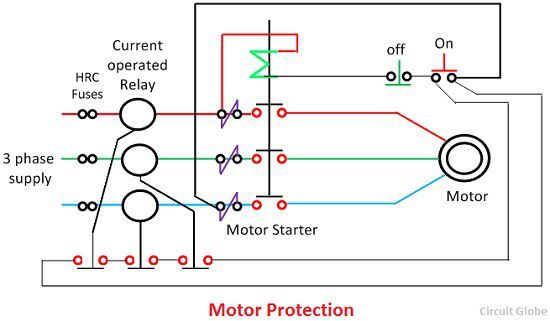

It is a critical aspect of power engineering focused on ensuring the reliability and durability of electrical motors. From small fans to massive industrial pumps, motors drive processes everywhere, and their failure can have far-reaching consequences. Protection systems defend against threats such as overload, phase failure, overheating, undervoltage, and short circuits. Modern protective schemes combine mechanical and electronic solutions to detect irregularities and disconnect power before significant damage occurs.

Electrical relay and fuse protection systems are designed to prevent damage to the motor by ensuring it operates within safe limits. Protective relays and solid-state devices can monitor the temperature to avoid overheating, while overload protection ensures the current does not exceed full load ratings. Modern systems often integrate with variable frequency drives, which provide smoother starting, improved efficiency, and added safeguards against faults that could compromise motor reliability.

Key Types of Motor Protection

-

Overload Protection: Protects motors from running at a current exceeding their rated capacity, which can cause overheating and insulation breakdown. Devices like thermal overload relays sense the heat generated and trip when necessary. Find a detailed explanation at Motor Overload Protection explained

-

Short-Circuit and Ground-Fault Protection: Circuit breakers and fuses rapidly disconnect faulty circuits, preventing catastrophic failures and fire hazards.

-

Phase Loss/Phase Imbalance Protection: Three-phase motors require a balanced supply. Phase failure relays monitor all phases and trip the motor if a disconnect or imbalance is detected.

-

Temperature Protection: Embedded thermistors or thermal switches can disengage the motor or raise an alarm if winding temperature exceeds safe limits.

-

Voltage/Current Monitoring: Undervoltage relays and current monitors prevent operation under unstable power conditions, minimizing stress on the motor’s windings.

Why Protection Matters

When a motor operates outside its designed parameters, it is vulnerable to damage that may not be immediately evident. For example, persistent overloads can degrade insulation, leading to short circuits that are costly to repair. Early detection ensures only minor repairs are necessary and helps keep operations running efficiently. Strong protective technologies also improve workplace safety by reducing the risk of fires and hazardous shocks stemming from motor faults. For more information about protection strategies and devices, visit our main Electrical Protection page.

Implementation in Real-World Applications

In industrial environments, motor protection is standard in manufacturing plants, water treatment facilities, and processing plants—anywhere motors operate for extended periods under variable loads. Typical protection setups might include:

-

Thermal overload relays in motor control centers

-

Fused disconnect switches for short-circuit protection

-

Digital protection relays that offer remote monitoring and programmable settings

-

Integrated temperature sensors for larger machines

Consistent maintenance and periodic electric motor testing ensure protective devices and circuits remain responsive and reliable.

Best Practices for Motor Protection

-

Understand the application: Determine the normal and abnormal operating conditions for each motor in your facility.

-

Proper sizing of protection devices: Overload relays and fuses must match the motor’s rating and duty cycle for optimal response.

-

Routine maintenance: Regularly inspect protection equipment, wiring, and motor health.

-

Continuous monitoring: Leverage modern monitoring systems that provide real-time alerts and diagnostics, enabling the prediction of failures before they occur.

-

Documentation and training: Maintain records of protection settings and educate operators and technicians on troubleshooting and resetting protective devices.

Incorporating these best practices extends the lifespan of equipment and minimizes lost productivity due to unexpected failures. Learn more about maintenance strategies at Electric Motor Maintenance and Diagnostics.

Electric motor protection is not merely a technical requirement—it is a foundational component of modern safety management, reliability engineering, and cost control in every sector that depends on motors. By deploying the right combination of overload protection, short-circuit devices, and temperature monitoring, organizations minimize risk and maximize operational uptime. As both equipment and protective technologies advance, regular training and upgrades will ensure systems remain robust for years to come.

Related Articles

Overcurrent Relay Protection

An overcurrent relay is a protective device that detects excessive current flow and triggers circuit breakers to prevent damage. Commonly used in power systems, it safeguards equipment from faults, short circuits, and overload conditions by monitoring current levels and operating thresholds.

What is an Overcurrent Relay?

An overcurrent relay plays a pivotal role in safeguarding electrical systems from the detrimental effects of excessive current flow.

✅ Detects and responds to excessive current levels.

✅ Protects electrical systems from faults and overloads.

✅ Works with circuit breakers for reliable power system safety.

This essential protection device detects abnormal current levels and initiates corrective action to prevent damage. Its primary objective is to ensure the continuity and stability of power supply systems in the power generation, transmission, and distribution industries. Overcurrent protection is achieved through a combination of intelligent sensing, precise time characteristics, and efficient operation, all of which contribute to the reliability of the electrical network. Understanding electrical protection systems is essential for preventing equipment damage and ensuring safe power distribution.

Substation Relay Protection Training

Request a Free Training Quotation

The functionality of an overcurrent relay revolves around the concept of current sensing and response. The function is activated when the current flowing through an electrical system surpasses a pre-determined threshold. By using time delay mechanisms, protection ensures that transient surges, such as those caused by switching operations or short-term inrush currents, do not trigger an unnecessary shutdown. The delay allows the system to distinguish between temporary fluctuations and genuine faults. This strategic approach prevents unnecessary interruptions while still offering robust overcurrent protection. Modern protective relays use advanced technologies to monitor fault conditions and coordinate with circuit breakers.

Diverse Types, Tailored Protection

Different types of overcurrent relay are employed to address specific protection needs. The instantaneous overcurrent relay, for example, responds immediately when the current exceeds a set threshold without any intentional time delay. This type trips the circuit breaker as soon as a fault is detected, making it ideal for severe short-circuit scenarios. On the other hand, an inverse time overcurrent relay employs a delay that is inversely proportional to the magnitude of the overcurrent. Higher currents result in shorter operating times, ensuring a faster response to more severe faults. Another variant, the inverse definite minimum time relay, combines features of both instantaneous and inverse time, offering a minimum time delay regardless of the current magnitude. Choosing the right circuit protection devices is vital for maintaining electrical reliability and minimizing downtime.

Comparison of Overcurrent Relay Types and Key Features

| Overcurrent Relay Type | Operating Principle | Key Advantages | Common Applications |

|---|---|---|---|

| Instantaneous Overcurrent | Trips immediately when current exceeds set value | Fast response, simple design | Short-circuit protection, motors |

| Definite Time Overcurrent | Trips after a fixed time delay | Adjustable delay, reliable coordination | Feeder and transformer protection |

| Inverse Time Overcurrent | Trip time inversely proportional to current | Better fault discrimination, selective protection | Distribution networks, transmission lines |

| Directional Overcurrent | Considers current direction and magnitude | Prevents false trips, improved selectivity | Parallel lines, ring networks |

| Numerical Overcurrent | Microprocessor-based with multiple settings | High accuracy, event logging, remote control | Modern power systems, smart grids |

The Intricate Mechanism

Certain types of overcurrent relays have extremely inverse time characteristics, and extreme inverse responses are crucial in managing complex electrical environments. These time characteristics provide greater flexibility in differentiating between fault conditions and transient disturbances. By incorporating extremely inverse time logic, the device is better equipped to coordinate with other protection devices, such as fuses and downstream protective devices, to achieve selective tripping. This coordination is essential in large interconnected power grids where multiple overcurrent relays must work in harmony.

A series of well-defined principles underpin operation. The sensing element of an overcurrent relay detects current fluctuations and activates a response mechanism. The operating time is carefully calibrated to ensure the protective device trips the circuit breaker at optimal times. This precision is achieved through the use of protection devices that incorporate advanced electronics and programmable logic. The result is a system that minimizes downtime and enhances system reliability.

Applications Across Industries

Applications of overcurrent relays extend across various industrial and commercial sectors. These protective devices protect critical equipment from overloads and short circuits in power generation plants. Power transmission networks prevent cascading failures by isolating faulted segments of the grid. Similarly, in distribution systems, they safeguard transformers, switchgear, and feeder circuits. The versatility of the overcurrent relay allows it to be deployed in diverse environments, ensuring the continuous operation of vital infrastructure. Proper power transformer protection ensures that critical equipment is shielded from overloads and internal faults.

The Imperative of Maintenance and Testing

Regular maintenance and testing of an overcurrent relay is indispensable to maintain its effectiveness. Periodic testing verifies the accuracy of the trip settings and ensures its ability to detect and respond to faults. Maintenance includes inspecting the device's physical condition, cleaning its components, and updating its firmware when necessary. Neglecting these practices can result in malfunction, leading to unplanned outages or equipment damage.

Effective testing procedures involve subjecting the overcurrent relay to simulated fault conditions. This process assesses its operating time, verifies the accuracy of its time delay, and ensures its ability to trip the circuit breaker as intended. By conducting routine maintenance and testing, operators can confirm that the protection system is ready to respond to any potential fault, thereby reinforcing the overall stability of the electrical system.

Frequently Asked Questions

What are the 3 types of overcurrent?

Overcurrent, a condition where the current flowing through a circuit exceeds its rated value, can manifest in three primary forms:

-

Short Circuit: This occurs when a low-resistance path is created between two points in a circuit, resulting in a sudden and significant increase in current.

-

Ground Fault: This happens when a portion of the circuit comes into contact with the ground, creating an unintended path for current to flow.

-

Overload: This arises when a circuit is subjected to a continuous current that exceeds its rated capacity for an extended period.

What is the difference between an overload relay and an overcurrent relay?

While both overload and overcurrent relays are designed to protect electrical systems from excessive current, they differ in their primary functions and response characteristics.

-

Overload Relay: Specifically designed to protect against overload conditions where the current exceeds the rated value for an extended period. They typically have a delayed response to allow for temporary overloads, such as motor starting currents.

-

Overcurrent Relay: A more general-purpose overcurrent relay that protects against overload and short-circuit conditions. They are more sensitive and can respond quickly to sudden increases in current.

What is the difference between 50 and 51 overcurrent relay?

In the numerical system used to classify the protective device, 50 and 51 relays are commonly used for overcurrent protection:

-

50 Relay: This type is primarily used for instantaneous overcurrent protection. It responds very quickly to high-magnitude fault currents, such as those caused by short circuits.

-

51 Relay: This device provides time-delayed overcurrent protection. It has a characteristic curve that defines the time it takes for the overcurrent relay to trip as a function of the magnitude of the fault current. This enables selective coordination with other protective devices within the system.

By understanding these distinctions, engineers can effectively select and apply an overcurrent relay to safeguard electrical systems from various fault conditions. A thorough short circuit analysis helps engineers evaluate system safety and select the right protective devices.

An overcurrent relay is an indispensable protection device that ensures electrical systems' safety and reliability. Their ability to sense current fluctuations, apply time delay logic, and precisely operate circuit breakers makes them vital to modern power systems. Different types—such as instantaneous, inverse time, and inverse definite minimum time relays—offer tailored protection for various operational scenarios. Incorporating extreme inverse and extremely inverse time characteristics further enhances system coordination. Routine maintenance and testing ensure the long-term reliability of these devices, preventing costly damage and ensuring uninterrupted power delivery. Through their seamless integration into power generation, transmission, and distribution networks, they uphold the safety and resilience of the global electrical infrastructure.

Related Articles