EMT Electrical Conduit

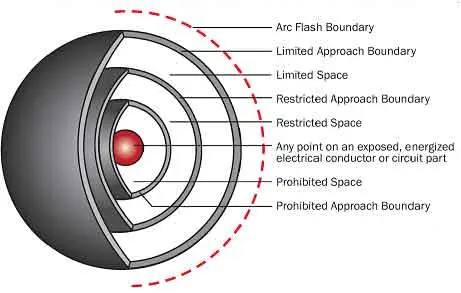

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

EMT electrical conduit, also called thin-wall conduit, is a lightweight metal tubing used to protect and route electrical wiring. Made from galvanized steel or aluminum, EMT conduit offers durability, easy bending, and cost-effective installation for residential, commercial, and industrial applications.

What is EMT Electrical Conduit?

EMT electrical conduit, also known as electrical metallic tubing, is a popular choice for protecting and routing wiring in residential, commercial, and industrial wiring projects. It is:

✅ Lightweight, thin-wall metal tubing made from steel or aluminum

✅ Protects and routes electrical wiring in buildings

✅ Easy to bend, cut, and install for versatile applications

Known for its lightweight, cost-effective design, EMT is often referred to as thin-wall tubing due to its slimmer structure compared to rigid alternatives. Its galvanized steel construction provides corrosion-resistant properties, making it suitable for a variety of environments, including both indoor and outdoor wiring installations. The lightweight design makes it easier to handle during installation, while the galvanized steel helps protect the wiring inside. While commonly used in dry locations, it can also be applied in wet locations with the appropriate fittings, such as compression couplings, to ensure a watertight seal. EMT’s ability to be installed in both exposed and concealed locations adds to its versatility. This article will explore its advantages, compare it to other tubing options, and discuss when it’s best to use.

Frequently Asked Questions

What are the advantages and disadvantages of using EMT electrical conduit?

One of the major advantages of EMT is its easy installation and versatility. Being lightweight, it’s easier to handle and can be bent with standard tools, making it suitable for a range of applications, from residential to industrial wiring. Additionally, EMT is cost-effective, fire-resistant, and non-magnetic, making it a safe and durable choice for many environments. However, it is not as strong as rigid alternatives, which makes it more prone to damage in environments where physical impact is likely. Therefore, it’s not recommended for hazardous locations or areas where heavy wear and tear are expected.

Sign Up for Electricity Forum’s Wiring Devices Newsletter

Stay informed with our FREE Wiring Devices Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

How does EMT compare to other types of EMT conduit?

Compared to rigid metal options, EMT is much more flexible and easier to install. While rigid types offer more durability, they require specialized tools and techniques, making installation more labour-intensive. EMT, on the other hand, is more cost-effective, as it requires fewer specialized tools, which helps reduce overall project costs. While rigid tubing might be preferred for heavy-duty applications, EMT works well for general-purpose commercial and residential wiring. In wet locations, PVC conduits are often preferred, but EMT can be used with the proper watertight fittings.

Is EMT electrical conduit suitable for outdoor use?

Yes, EMT can be used for outdoor wiring if installed with appropriate weatherproof fittings that ensure a watertight seal. While primarily used for indoor wiring, its corrosion-resistant properties allow it to be safely used outdoors in exposed locations. To ensure long-term performance in wet locations, it’s important to install EMT with weatherproof connectors, clamps, and straps. Always follow NEC guidelines for compliant installation.

How do I bend EMT conduit, and what tools are needed?

Bending EMT is relatively simple due to its flexibility. A standard bender can be used to create precise angles, allowing the tubing to navigate around obstacles or fit into tight spaces. When bending EMT, it’s important to ensure the bend doesn’t deform the tubing, as this can damage the wiring inside. Once the bends are made, set-screw or compression couplings are used to securely connect the sections.

EMT is a versatile, cost-effective, and corrosion-resistant option for a variety of installations, from residential to industrial wiring projects. Its lightweight and easy-to-bend properties make it ideal for both exposed and concealed locations. While it may not be as strong as rigid tubing, the balance of advantages makes it a suitable option for many indoor and outdoor wiring applications. By following proper installation techniques and using the right fittings, EMT can provide a durable, long-lasting solution that meets safety standards.