Latest Power Quality Articles

Optimizing Equipment Maintenance with Hour Meters

Optimizing Equipment Maintenance with ENM meters boosts predictive maintenance, condition monitoring, and power quality analytics, enabling IoT/SCADA integration, reliability-centered maintenance, and downtime reduction for electrical assets across industrial power systems.

What Is Optimizing Equipment Maintenance with ENM Meters?

Using ENM meters to drive predictive maintenance, power quality insights, and asset reliability in electrical systems.

✅ Real-time power quality, harmonics, and load profiling metrics

✅ Predictive maintenance via trend analytics and alarm thresholds

✅ Integrates with SCADA, CMMS, and IIoT for asset workflows

Proper equipment maintenance is crucial for maximizing uptime, extending service life, and minimizing unexpected failures. One of the most effective tools for achieving this is the hour meter—a simple yet powerful device that tracks the duration of equipment operation. By accurately logging run-time, hour meters enable maintenance teams to schedule service intervals based on actual usage rather than relying on guesswork or calendar dates. ENM Company, a leading manufacturer of counting instruments, offers a range of hour meters specifically engineered to support this process in both industrial and commercial settings. Understanding the fundamentals of power quality helps teams align maintenance with the electrical environment.

Why Hour Meters Matter for Maintenance

Instead of relying on reactive maintenance or vague schedules, hour meters enable condition-based servicing. This not only helps avoid premature part replacements but also reduces the risk of catastrophic failures caused by overuse. Maintenance activities such as oil changes, filter replacements, and system inspections can be triggered precisely when needed—based on actual run-time data. This approach improves equipment efficiency, lowers operational costs, and enhances safety. When paired with targeted power quality monitoring, hour meters add context about voltage events that can refine service intervals.

ENM Hour Meters for Different Applications

ENM’s product line offers a variety of hour meters designed to meet specific application needs, whether for DC systems, AC-powered machinery, or vibration-based equipment.

T40 Quartz DC Hour Meter

Ideal for battery-powered or DC-powered systems, the T40 Quartz DC Hour Meter is a low-power, tamper-resistant solution that ensures precise time tracking without requiring battery backup. It is especially well-suited for vehicles, generators, and industrial machines where DC voltage is present. Its compact, sealed design ensures durability and long-term reliability. Download the T40 Datasheet here.

T50 Quartz AC Hour Meter

For AC-powered equipment, the T50 Quartz AC Hour Meter delivers robust performance using a quartz-crystal time base. Its high accuracy and simple panel mounting make it ideal for tracking runtime on motors, compressors, and HVAC systems. Designed for rugged use, the T50 performs reliably even in harsh electrical environments. Download the T50 Datasheet here. Facilities tracking motor loads often integrate a power factor meter alongside the T50 to correlate runtime with reactive power trends for improved efficiency.

T56E Vibration Activated LCD Hour Meter

When electrical connections are impractical or unavailable, the T56E Vibration Activated LCD Hour Meter offers an innovative solution. It detects equipment operation via vibration and features three separate time-tracking modes. With adjustable vibration sensitivity and no need for wired installation, it is perfect for portable or gas-powered equipment such as lawn mowers, construction tools, and small engines. Its LCD display is easy to read and stores data securely, even when power is removed. Download theT56E Datasheet here. For intermittent issues on small engines, referencing proven power quality troubleshooting techniques can guide root-cause analysis beyond simple runtime metrics.

Improved Efficiency and Lifecycle Management

By deploying hour meters across your equipment fleet, you gain the ability to forecast wear and tear, plan downtime strategically, and align spare parts inventory with real-world usage patterns. These devices act as silent sentinels, gathering essential data that supports predictive maintenance and improves the return on investment (ROI) of your capital equipment. Combining hour-based service data with a power quality analyzer helps identify electrical stressors that accelerate wear on critical components.

Industries That Benefit from Hour Meter Use

-

Manufacturing: Track runtime of CNC machines, presses, and conveyors. In plants with sensitive electronics, adherence to quality of electricity guidelines supports consistent output.

-

Construction: Monitor portable equipment, generators, and compactors. On sites with generator-fed systems, evaluating high resistance grounding options can reduce fault energy while maintaining service continuity.

-

Fleet Management: Service vehicles based on engine hours, not mileage.

-

HVAC: Schedule regular maintenance on fans, pumps, and air handlers.

-

Agriculture: Maintain tractors, irrigation systems, and diesel engines efficiently.

Optimizing equipment maintenance isn’t just about keeping machines running—it’s about running them smarter. ENM hour meters such as the T40, T50, and T56E give businesses the tools they need to make data-driven maintenance decisions. With reliable time-tracking across a wide range of electrical and mechanical systems, these meters provide an essential layer of operational intelligence that helps prevent downtime and improve performance.

ENM Company is a U.S.-based manufacturer specializing in electronic and electromechanical counters, hour meters, tachometers, and custom-engineered instruments. Founded in 1957, ENM has built a reputation for quality, innovation, and reliability, serving industries ranging from manufacturing and construction to agriculture and transportation. With a strong focus on precision time-tracking and monitoring solutions, ENM products are designed to enhance operational efficiency and equipment maintenance across a wide range of applications.

To learn more about these products and how they can support your maintenance goals, visit ENM Company’s official website.

For More Information

ENM Company

5617 Northwest Highway

Chicago, IL 60646-6135

Phone: 773 775-8400

Toll Free : 888 372-0465

Fax: 773 775-5968

Email: customerservice@enmco.com

Related Articles

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Power Quality And Harmonics Explained

Power quality and harmonics affect voltage distortion, THD, power factor, and equipment reliability; nonlinear loads, waveform distortion, IEEE 519 compliance, harmonic filters, and active mitigation ensure grid stability, efficiency, and PQ analysis accuracy.

What Are Power Quality and Harmonics?

They describe voltage waveform integrity and harmonic distortion levels that impact power factor, losses, and compliance.

✅ Measure THD, voltage sags/swells, flicker, and unbalance per IEEE 519

✅ Mitigate with passive/active filters, reactors, and tuned capacitor banks

✅ Improve power factor, reduce losses, protect drives and transformers

More electronic equipment in the workplace raises the likelihood of potential interactions with the electric distribution system and requires a more sophisticated approach to preventing these interactions. Common power quality concerns, including voltage sags, swells, and surges, have led to the increased use of additional facility equipment, such as uninterruptible sources and battery-supported systems, to increase electrical reliability. In addition, signal interactions in sensitive equipment can be difficult to trace. Energy managers can engage in a number of practices that will improve overall power quality in a facility and reduce the interactions due to harmonic currents in the load devices. For foundational context, resources explaining what power quality is can help practitioners align terminology and expectations.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Beyond formal courses, implementing continuous power quality monitoring provides data to validate improvements and prioritize corrective actions.

FACILITY POWER DISTURBANCES

Facility design requires the consideration of a variety of load-source interactions. The power quality consensus standards of the Institute of Electrical and Electronic Engineers (IEEE 1100-1999) can provide a basis for understanding these loadsource interactions. The four areas of load-source interactions are:

- Electrical wiring and grounding of a facility

- Surge (transient) protection system

- Harmonics proliferation demands

- Electrical power reliability

Together, these domains shape the quality of electricity that equipment ultimately experiences in day-to-day operation.

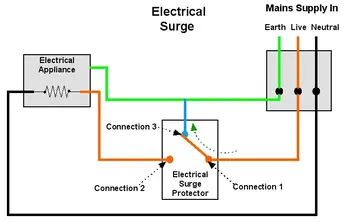

The electrical wiring and grounding of a facility includes the digital signal system and how it operates in the conventional wiring plan found in most facilities, as outlined by the National Electrical Code (NEC). The code provides for the safety of personnel and equipment, and specifically says that the equipment may not operate well (NEC 90-1.B); the NEC has no consensus for how to enhance operating integrity. The task is to find ways of turning electrical noise away from sensitive electronic devices and into the areas of the facility where the noise does no harm. The surge protection system includes power supplies, signal drivers, and receivers, which must be protected from high-speed surges traveling on the wiring. The IEEE C.62 standard describes a surge as a very fast occurrence of voltage to the system, which could come from a lightning strike, the operation of a lightning arrester, a utility switching operation, or even from energy moving in the earth. A clearer grasp of transient voltage events enables better coordination between grounding strategy and surge protective devices.

Since most of the printed circuits and chips used in modern electronic equipment cannot withstand more than eight to ten volts, lightning arresters and surge protection systems are needed. Many times, the main electrical service entrance is protected, but telephone, data, paging systems, fire detection, and other digital data systems must also be protected. Electronic loads also produce harmonics. Harmonics are different electrical sine wave frequencies that power supplies require of the electrical source, whether that source is the local utility, distributed generation units, or both. Solutions for electrical power reliability cause the remaining concerns. The term electric power reliability includes electrical continuity, not only the long-term continuing supply of electric energy, but also the behavior of the power system under fault and other short-term disturbances. These problems have always been resolved by purchasing a special power conditioner to make up for the power system's "deficiency". When symptoms persist, structured power quality troubleshooting can isolate sources and guide remediation.

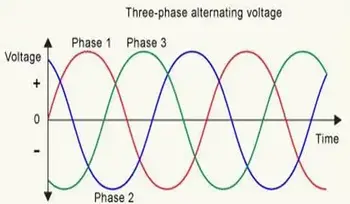

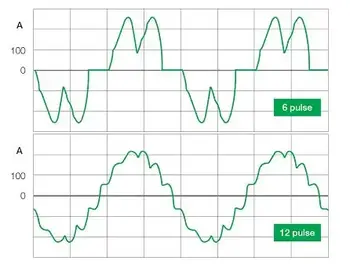

HARMONIC CURRENTS AND VOLTAGES

Harmonics in power circuits are frequencies that are integer multiples of a fundamental frequency generated by non-linear electrical and electronic equipment. The fundamental line frequency (50 or 60 Hz) combines with the harmonic sine waves to form repetitive, non-sinusoidal distorted wave shapes. Total harmonic distortion (THD) is a measure of the amount of distortion produced as current flows from the power line. This line current can flow at the fundamental frequency (60 Hz in the U.S.) or it may be combined with odd harmonic currents (multiples of the fundamental) such as 180 Hz (3rd harmonic), 300 Hz (5th harmonic), and 420 Hz (7th harmonic). While different in origin, voltage flicker can coexist with harmonic distortion and affect end-user experience.

The THD value is the effective value of all the harmonic currents added together, compared with the value of the fundamental current. For example, 20% THD means that the total harmonic current is equal to 20% of the total 60-Hz current. Contemporary electronic loads have different current and voltage wave shapes. For example, the voltage may still appear to be a sine wave, but the current waveform appears peaked, as if "squeezed" together. Such loads contain what is called a "switching" power supply. These power supplies operate at very high switching speeds and are very energy-efficient, but demand that the current provided to them consist of an unusually high amount of 3rd harmonics. These power supplies actually "request" their power in "pulses", first keeping the power turned off at the beginning of the cycle, then turning on the pulse, and then turning off again at the end of the first half cycle. This pattern appears first in the positive half cycle, then in the negative half cycle, and repeats in the same manner as the original sine wave. Practical verification typically relies on a power quality analyzer to capture waveforms, quantify THD, and document corrective results.

From: Power Quality & UPS Handbook, Vol 11, The Electricity Forum

Related Articles

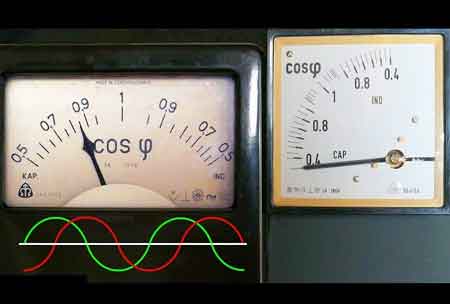

Lagging Power Factor and How to Correct It

A lagging power factor occurs when current lags behind voltage, typically in inductive loads like motors or transformers. It reduces electrical efficiency, increases losses, and may incur utility penalties. Correction involves using capacitors or power factor correction equipment.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

What is "lagging power factor"?

Lagging power factor, caused by inductive loads such as motors and transformers, leads to energy inefficiencies, higher operational costs, and system performance issues.

✅ Occurs when current lags behind voltage in AC circuits due to inductive loads

✅ Common in systems with motors, transformers, or fluorescent lighting

✅ Leads to inefficiencies, increased energy costs, and potential utility surcharges

Industrial electricians must understand how it arises, how it affects reactive energy flow, and how to correct it through proven engineering methods. Improving power factor (PF) not only boosts electrical efficiency but also helps facilities avoid penalties and reduce stress on equipment. A deep dive into power quality reveals the connection between harmonic distortion and PF in industrial settings.

Understanding Lagging vs. Leading Power Factor

In AC systems, the phase relationship between voltage and current determines whether a system exhibits a lagging or leading PF. The classic mnemonic “ELI the ICE man” helps explain this: in inductive circuits (ELI), voltage leads current, producing a lag; in capacitive circuits (ICE), current leads voltage, creating a leading power factor. Most industrial equipment produces it, which must be managed to ensure efficient operations. To grasp the full picture of phase relationships, it is essential to understand the breakdown of leading vs. lagging power factor and their impact on reactive loads.

What is an Inductive Load?

An inductive load—such as a motor or transformer—stores energy in magnetic fields. This delays the current relative to the voltage, creating a phase shift. The greater this phase angle, the lower the PF and the more inefficient the system becomes. This inefficiency leads to increased current demand, which strains distribution systems and results in higher utility charges.

Reactive Power and Apparent Power

Reactive power (Q), measured in VARS, does no useful work but circulates within the system due to the voltage-current phase shift. It combines with real power (watts) to form apparent power (S), measured in VA. A high amount of Q increases total current, leading to voltage drops, energy losses, and reduced system efficiency. Read more about this in our What Is Reactive Power? article.

The Power Triangle

The power triangle visually illustrates the relationship between real power, Q, and S. As the angle between voltage and current increases (due to inductive loads), the triangle’s hypotenuse (S) grows larger relative to real power, signalling a worsening PF. Minimizing this angle brings the system closer to unity PF.

PF Correction Methods

PFC involves adding capacitive loads that generate leading Q to cancel out lagging Q from inductive equipment. Correction can be done through:

-

Capacitor banks: Parallel-connected capacitors provide targeted compensation for inductive loads.

-

Automatic PFC units: These dynamically adjust compensation based on real-time conditions.

-

Synchronous condensers: Rotating machines that offer PFC and voltage regulation.

For a deep insight into Power Factor Correction Methods, read this article.

Harmonic Distortion and PF

Non-linear loads, such as variable-frequency drives and electronic devices, introduce harmonics—distorted waveforms that worsen PF and increase reactive power (Q) demand. Harmonic filters or tuned capacitor banks are often required to mitigate their effects. This article on Harmonic Distortion and PQ explains the most important factors.

Impact on Electrical Efficiency

LPF increases current demand, leading to:

-

Elevated voltage drop

-

Greater conductor losses

-

Increased equipment heating

-

Shortened lifespan of transformers and cables

These issues collectively degrade system reliability and raise operational costs.

Voltage Drop and Load Impact

A lower PF intensifies voltage drop across electrical systems, particularly over long cable runs or with undersized conductors. This can cause sensitive equipment to malfunction or degrade over time. Read all about Voltage Drop and Its Effects in this article.

Frequently Asked Questions

What causes a it?

It is caused by inductive loads, such as motors, transformers, and fluorescent lighting, where current lags behind voltage due to the storage of magnetic energy.

How does it affect an electrical system?

It increases current demand, causing higher energy losses, greater voltage drop, equipment overheating, and potential utility penalties.

How can you correct it?

It can be corrected by installing capacitors, synchronous condensers, or automatic PFC equipment to balance Q.

What are the consequences?

It increases current demand, resulting in energy losses and higher utility bills. It can degrade equipment, increase heat, and trigger utility penalties in industrial systems.

How is it corrected?

The most common method is installing PFC capacitors, which introduce leading Q to balance the system. Synchronous condensers and automatic PFC systems are also used in dynamic environments.

Why is it important in industrial settings?

Addressing it is essential in industrial settings because it directly affects energy efficiency and operational costs. With a lagging PF, facilities may incur additional charges from utility providers and risk overloading their infrastructure due to higher current demands. By improving PF, companies can reduce these costs, enhance system reliability, minimize equipment wear and tear, and contribute to more sustainable energy usage.

Understanding it is crucial for optimizing electrical systems, especially in industrial settings with prevalent inductive loads. By implementing PF correction techniques, such as installing capacitor banks, electricians can reduce energy waste, lower costs, and enhance the overall efficiency and reliability of the distribution system. For a practical example, learn how a power factor meter helps monitor and improve performance in systems affected by a lagging PF.

Related Articles

Total Harmonic Distortion: THD Explained

Total Harmonic Distortion (THD) measures unwanted voltage or current harmonics that distort AC waveforms, lowering power quality and efficiency. Discover how THD impacts electrical systems and learn effective methods to reduce harmonic levels for reliable performance.

What is Total Harmonic Distortion?

Total Harmonic Distortion quantifies the harmonic content of a voltage or current waveform, expressed as a percentage of the fundamental frequency.

✅ Indicates overall power-quality health for equipment and grid

✅ Helps diagnose overheating, vibration, and energy losses

✅ Guides filter design and IEEE 519 compliance planning

Total harmonic distortion (THD) is a crucial factor in evaluating power quality in electrical systems. THD measures the level of distortion in a waveform caused by the presence of harmonics. Harmonics are multiples of the fundamental frequency of the waveform, which can result in a distorted waveform with irregular peaks and troughs. Therefore, THD is expressed as a percentage of the fundamental frequency of the waveform. To understand the broader context of THD, it's helpful to start with a clear explanation of what is power quality, as harmonic distortion directly impacts voltage and current stability.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

The distortion in the current waveform can be analyzed using Fourier analysis, which breaks down the waveform into its individual harmonic components. THD measurement is then used to quantify the waveform's distortion level. THD is calculated as the square root of the sum of the individual harmonic components' squares divided by the fundamental frequency's RMS voltage. This value is expressed as a percentage of the fundamental voltage. Nonlinear loads that generate harmonics may also cause voltage drops and irregularities, making it essential to monitor voltage flicker and distortion.

Total harmonic distortion measurement is essential for assessing power quality in electrical systems. However, high THD values can cause significant problems for sensitive equipment, including audio systems. Audio systems require a clean, sinusoidal signal with minimal distortion levels. Additionally, the input signal and output signal must match the sine wave to minimize crossover distortion. In such cases, THD is a crucial parameter that must be carefully controlled.

Voltage distortion caused by THD is also a concern in power systems. The voltage stress within a capacitor is related to the peak value of the voltage waveform, not its heating value. As such, THD is not a good indicator of voltage stress within a capacitor. For engineers analyzing THD in field environments, a power quality analyzer provides critical insight into waveform integrity and harmonic content.

Total Harmonic Distortion Limits and Effects

| THD (%) | Power Quality | Impact on Equipment | Recommended Action |

| < 3% | Excellent | No significant effects | No action needed |

| 3–5% | Acceptable | Slight heating, minor interference in sensitive devices | Monitor system regularly |

| 5–8% | Marginal | Equipment derating, increased transformer and motor heating | Consider harmonic filters |

| 8–10% | Poor | Distortion affects electronics, overheating risk increases | Install passive/active filters |

| > 10% | Unacceptable | Severe waveform distortion, equipment failure risk | Urgent corrective action required |

Analysts have developed total demand distortion (TDD) to address this limitation to characterize current distortion levels. TDD refers to the peak demand load current's fundamental frequency, rather than the fundamental frequency of the present sample. TDD is used in IEEE STD 519-1992 guidelines to assess current distortion levels in power systems.

Power quality is a critical issue in electrical systems, and Total harmonic distortion measurement is an essential tool for ensuring high-quality power. In addition to THD, other parameters such as voltage distortion, frequency domain, and signal processing must also be considered to ensure proper system response characteristics.

The root means square (RMS) voltage is a critical parameter for calculating THD. The RMS voltage is the square root of the sum of the squares of the individual voltages in the waveform. The fundamental frequency is the lowest frequency component of the waveform, and all other harmonic frequencies are multiples of this frequency. If your system includes capacitive components, understanding the capacitor voltage rating is vital, as high THD can stress capacitors beyond safe limits.

THD measurement is performed using a THD analyzer, a specialized instrument designed to accurately measure a waveform's harmonic components. The analyzer processes the waveform using signal processing techniques, such as Fourier analysis, to identify and quantify the individual harmonic components. For those managing grounding systems, high THD levels can interfere with effective electrical grounding, increasing risks and reducing equipment lifespan.

THD Measurement and Standards

Waveform distortion caused by nonlinear loads can significantly degrade signal integrity in electrical systems, making it essential to analyze the harmonic spectrum using a reliable THD analyzer. These analyzers break down the complex waveform into its individual harmonic components, helping engineers assess compliance with IEEE 519 and other power quality standards. Maintaining waveform purity ensures that sensitive equipment operates efficiently and without error, particularly in systems where stable RMS voltage is critical. By identifying the sources and magnitude of distortion, organizations can take corrective action to restore clean waveforms and improve overall system performance.

IEEE 519 THD Limits by Voltage Level

| Voltage Level (System Voltage) | Maximum THD for Voltage (%) | Maximum Individual Harmonic (%) |

|---|---|---|

| Below 1 kV | 5.0% | 3.0% |

| 1 kV to 69 kV | 3.0% | 2.0% |

| 69.1 kV to 161 kV | 2.5% | 1.5% |

| Above 161 kV | 1.5% | 1.0% |

Frequently Asked Questions

How is THD calculated?

THD is calculated as the square root of the sum of the individual harmonic components' squares divided by the fundamental frequency's RMS voltage. This value is expressed as a percentage of the fundamental voltage. Harmonic content also plays a crucial role in assessing the balance between apparent power and real power, particularly in distorted systems.

What are the sources of distortion in electrical power systems?

Nonlinear loads are the primary source of distortion in electrical power systems. These loads do not follow Ohm's law, meaning that the current drawn by the load is not proportional to the voltage applied to it. Instead, the current waveform is distorted, resulting in voltage distortion and harmonic frequencies multiples of the fundamental frequency.

What are the effects of distortion on electrical equipment?

High levels of distortion can cause significant problems for sensitive equipment, including audio systems. Audio systems require a clean, sinusoidal signal with minimal distortion levels. Additionally, distortion can cause equipment to overheat, resulting in damage and a reduced lifespan.

How can distortion be reduced or eliminated in electrical systems?

Filtering and other mitigation techniques can reduce or eliminate distortion in electrical systems. For example, filtering can remove harmonic frequencies from the waveform, while other techniques, such as power factor correction, can help reduce the distortion level. Harmonics significantly affect power factor correction, often requiring filters or capacitor banks to maintain system efficiency.

What is the difference between THD and individual harmonic distortion?

THD measures the total amount of distortion in a waveform caused by the presence of harmonics. On the other hand, individual harmonic distortion measures the distortion caused by a specific harmonic frequency. Both measures are essential for assessing power quality in electrical systems.

What does THD tell you?

THD tells you the level of distortion in a waveform caused by the presence of harmonics. This information is crucial for evaluating power quality in electrical systems and identifying potential issues that impact equipment performance and lifespan.

Is 0.5 THD good?

0.5 Total harmonic distortion is considered high and may cause problems for some applications. Generally, a THD of less than 5% is acceptable for most applications.

What are the effects of high THD?

High levels of Total harmonic distortion can cause significant problems for sensitive equipment, including audio systems. It can also reduce the efficiency of electrical systems, resulting in increased energy consumption and decreased overall efficiency. Additionally, high levels of THD can cause equipment to overheat, resulting in damage and a reduced lifespan.

Related Articles

What is Surge Suppression?

What is surge suppression? It’s the mitigation of transient voltage and overvoltage spikes using surge protectors/SPDs with MOVs, TVS diodes, grounding, and filtering to protect equipment, improve power quality, and ensure system reliability.

What Is Surge Suppression?

Surge suppression limits transient overvoltage with SPDs to protect equipment and maintain power reliability.

✅ Diverts surges via SPDs using MOVs, GDTs, or TVS diodes

✅ Limits clamping voltage, let-through energy, and response time

✅ Requires proper grounding, coordination, and standards compliance

A surge suppressor can be the first and best defense against the instant or gradual destruction of electrical equipment. Compared to the replacement cost of a computer or the costly impact of data loss, surge suppressors are very inexpensive. Surge protection is a defense against damage from extremely high voltages that can be caused by lightning strikes, short circuits somewhere on the line, or switching equipment on or off line. Until the introduction of solid state devices, most AC powered equipment was too robust to be upset by surging power. Understanding how transient overvoltages stress dielectric barriers and semiconductor junctions underscores the value of early protection.

However, modern electronic equipment such as computers, telecommunications equipment and controllers is vulnerable to surges and the damage they can cause. Many people think of surge damage as caused by a single catastrophic event such as a lightning strike. While lightning is one of the most powerful and destructive surges, it does not occur frequently in our service territory. Small surges can occur several times a day or a hundred times an hour, ranging from several thousand volts to under 100 volts. These repeated smaller surges can eventually degrade electronic equipment. Power surges can also be generated by equipment in your facility such as:

- Elevators

- Office machines

- HVAC equipment

- Electric motor starters

During startup, motors can draw substantial inrush surge current that propagates through distribution panels and stresses sensitive loads.

Utility operations such as switching may also cause surges that can be carried along utility lines. When the surge reaches an office, factory, or home, it may still have enough energy to jump across switches, even those that are turned off, and damage equipment. An understanding of surges, noise and the serious problems they cause will help you protect valuable equipment from these invisible, extremely fast, and destructive forces. Assessing these conditions within a broader power quality framework helps prioritize monitoring, grounding, and protective coordination.

Why Do We Need Protection?

Solid state devices depend on consistent, high quality power. A single, powerful surge literally melts, welds, pits and burns its way through solid state circuits. Damage from surges can be classified into three categories:

- Hard failures which cause permanent damage requiring repair or replacement of electronic components,

- Upsets which are temporary malfunctions or glitches and usually do not cause permanent damage, and

- Latent failures resulting from continuous exposure to smaller, non-catastrophic surges which erode equipment performance and eventually cause hard failure.

For facilities in storm-prone regions, integrated lightning protection systems further reduce exposure to catastrophic surge energy.

Surges also create noise which can upset sensitive electronic equipment as well as alter or completely destroy stored data. Noise interference is actually a series of low level surges, typically between 10 volts to less than a volt. In parallel, understanding power quality and harmonics helps distinguish noise-related errors from true overvoltage events.

Types of Surge Suppressors

The most common type of suppressors are diverters. Diverters are connected in parallel between any two conductors. Generally, they are line to line, line to neutral, or neutral to ground. There are two basic forms of diverting devices: clamps and crowbars. Clamps - Voltage-clamping devices simply limit the surge. However, these devices have a changing impedance depending on the current flowing through them or the voltage appearing across them. Metal-oxide varistors (MOV) and avalanche diode suppressors are examples of clamps. Metal-oxide varistors (MOVs) operate in the nanosecond range and were originally designed to protect electric motors. The disadvantage here is a limited pulse life. Each time an MOV suppressor reacts to a surge, its performance ability lessens. Therefore, it is difficult to predict an MOV product’s life.

It depends primarily on the number and frequency of surges it experiences. Ultimately, it will fail. It is important to plan for replacement of the MOV components. Silicon avalanche diodes respond within nano seconds to clamp excessive voltage but have low energy dissipation characteristics. Further, a surge that exceeds an avalanche suppressor’s rating could get through to the equipment or destroy the surge suppressor. These are rarely used due to short life and limited use. Crowbar - When an overvoltage occurs, the crowbar devices change from a highimpedance to a low-impedance state. This low-impedance state then offers a path to ground, shunting unwanted surges away from sensitive circuits. The effectiveness of any clamp or crowbar depends on a low-impedance grounding system that can return surge energy safely without creating dangerous potential differences.

Gas discharge tubes are one currently available crowbar device. For radio and TV antennas, a spark gap device may be the principal lightning protection. Gas discharge tubes offer a low resistance path for large currents to shunt highcurrent transients to ground and dissipate energy in the form of light and heat. At service entrances, appropriately rated lightning arresters coordinate with downstream suppressors to limit steep-front impulses before they reach branch circuits.

Related Articles

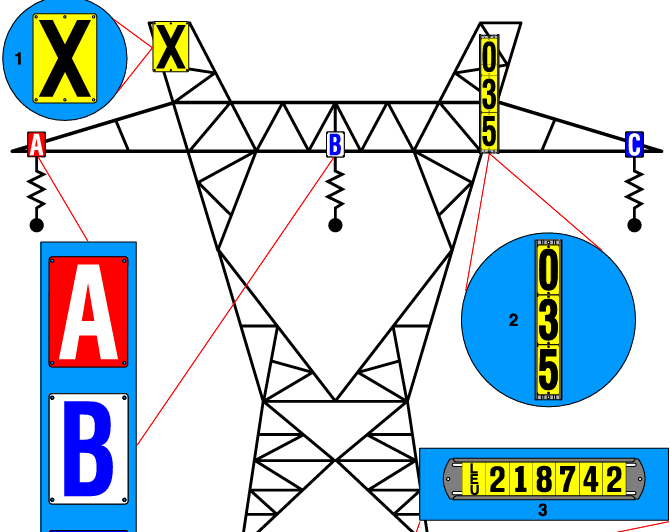

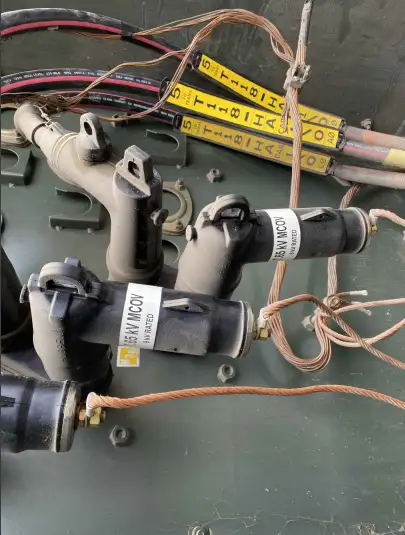

Three-Phase Power Calculation

Three phase power calculation helps determine the total power in a three-phase electrical system. It’s essential for electrical load planning, system efficiency, and safety. Learn the formulas for balanced and unbalanced loads, real power, apparent power, and reactive power.

What is: "Three Phase Power Calculation"?

A three phase power calculation is used to evaluate electrical power in industrial and commercial systems.

✅ Calculates real, reactive, and apparent power in three-phase circuits

✅ Essential for electrical design, efficiency, and load balancing

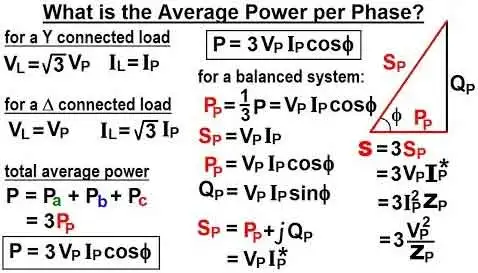

✅ Supports both balanced and unbalanced load analysis

Three phase power is vital to many industrial and commercial applications due to its efficiency and ability to handle high loads. Calculating three-phase power involves considering several key factors, including voltage, current, and power factor. The type of connection being used, the power triangle, and the power factor are also important considerations in three-phase power calculations. Understanding the basics of three-phase power calculation can help ensure the efficient and effective use of electrical power in various applications. For a broader overview of power parameters in commercial systems, visit our Power Quality resource hub covering grounding, harmonics, and voltage behaviour.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

To calculate the total power of a three-phase system, the formula used is as follows:

Total Power (W) = √3 × Voltage (V) × Current (A) × Power Factor

This formula assumes that the three-phase system consists of three separate phases, each with its own voltage and current. Therefore, the square root of three (√3) is a factor that is included to account for the relationship between the line-to-line voltage and the line-to-neutral voltage in a three-phase system.

To calculate the power in each phase of a three-phase system, the formula used is as follows:

Phase Power (W) = Voltage (V) × Current (A) × Power Factor

This formula is similar to the formula for calculating the total power of a three-phase system but only considers the voltage and current in one phase.

There are two main types of three-phase connections: delta and star (also known as wye). In a delta connection, the three-phase power supply is connected in a triangle configuration, with each phase connected to the next. Each phase is connected to a central neutral point in a star connection, creating a Y-shaped configuration. The type of connection being used can affect the voltage and current in the system and should be taken into account when calculating three-phase power. Explore the difference between apparent power vs real power to ensure proper sizing of equipment and accurate energy billing.

The power triangle is a visual representation of the relationship between different types of power in a three-phase system. The power triangle consists of three sides: real power, reactive power, and apparent power. Real power is the power used to perform useful work, while reactive power is the power required to create and maintain magnetic fields. Finally, apparent power is the combination of both real and reactive power.

-

To better understand how apparent power factors into three-phase calculations, explore the relationship between real and reactive components in AC systems.

-

For precise engineering estimates, use our apparent power calculator to quickly determine kVA based on voltage and current.

The power factor is also a crucial consideration in three-phase power calculations. The power factor is a measure of how efficiently the system uses power. A low power factor can lead to inefficiencies in the system and increased energy costs. To calculate the power factor in a three-phase system, the formula used is as follows:

Power Factor = Real Power (W) ÷ Apparent Power (VA)

The line-to-line voltage and line-to-neutral voltage in a three-phase system can also be calculated using the following formulas:

Line-to-Line Voltage (V) = √3 × Line-to-Neutral Voltage (V)

Line-to-Neutral Voltage (V) = Line-to-Line Voltage (V) ÷ √3

The total current can be divided by the square root of three to calculate the amps per phase in a three-phase system. This is because the current in each phase is lower than the total current in a three-phase system. The formula used to calculate amps per phase is:

Amps per Phase (A) = Total

The total current can be divided by the square root of three to calculate the amps per phase in a three-phase system. This is because the current in each phase is lower than the total current in a three-phase system. The formula used to calculate amps per phase is:

Amps per Phase (A) = Total Current (A) ÷ √3

Another important calculation in three-phase power is converting kilowatts (kW) to amperes (A). This can be done using the formula:

Amps (A) = (kW x 1000) ÷ (√3 x Voltage (V))

This formula assumes that in a three-phase system, the voltage is measured between phases, whereas in a single-phase system, the voltage is measured between a phase and the neutral.

In a three-phase system, the power factor is typically represented by the symbol cos φ. This value measures the phase angle between the voltage and current in the system. A high power factor indicates that the voltage and current are in phase with one another, while a low power factor indicates that they are out of phase.

Frequently Asked Questions

How do you calculate power in 3 phase supply?

To calculate power in a three-phase system, use the formula:

Total Power (W) = √3 × Voltage (V) × Current (A) × Power Factor

Why do we calculate 1.73 for 3-phase power?

We calculate 1.73 (the square root of 3) for three-phase power because the voltage measured in a three-phase system is line-to-line, whereas in a single-phase system, it is line-to-neutral. Therefore, the total voltage across a three-phase system is higher than that across a single-phase system.

How do you calculate 3-phase voltage?

The line-to-neutral voltage in a three-phase system can be found by dividing the line-to-line voltage by the square root of three. This is because the line-to-line voltage is higher in a three-phase system than the line-to-neutral voltage.

How do you calculate amps per phase in a 3-phase system?

To calculate amps per phase in a three-phase system, divide the total current by the square root of three. This is because the current in each phase is lower than the total current in a three-phase system. The formula used to calculate amps per phase is:

Amps per Phase (A) = Total Current (A) ÷ √3

What is three-phase power, and how is it different from single-phase power?

Three-phase power is a type of electrical power consisting of three alternating currents that are 120 degrees out of phase with one another. This allows for more efficient use of power, as the power flow is continuous and more stable than in a single-phase system composed of only one alternating current.

How do you calculate the total power of a three-phase system?

To calculate the total power of a three-phase system, use the formula:

Total Power (W) = √3 × Voltage (V) × Current (A) × Power Factor

How do you calculate the power in each phase of a three-phase system?

To calculate the power in each phase of a three-phase system, use the formula:

Phase Power (W) = Voltage (V) × Current (A) × Power Factor

What is a power factor, and how does it affect three-phase power calculations?

The power factor is a measure of how efficiently the system uses power. In an ideal system, the power factor would be 1, indicating that all of the power being used is being put to productive use. However, in practice, the power factor can be affected by several factors, such as inductive loads and reactive power. Therefore, power factor is a crucial consideration in three-phase power calculations, as it impacts the system's efficiency and can result in increased energy costs. Learn how power factor is calculated to improve system efficiency and minimize losses in industrial applications.

What is the difference between active, reactive, and apparent power in three-phase systems?

Active power is the power actually used to perform useful work, while reactive power is the power required to create and maintain magnetic fields. Finally, apparent power is the combination of both real and reactive power. Understanding the relationship between active, reactive, and apparent power is crucial in three-phase power calculations, as it helps identify inefficiencies in the system. Explore the difference between apparent power and real power to ensure proper equipment sizing and accurate energy billing.

What is a power triangle, and how is it used in three-phase power calculations?

The power triangle is a visual representation of the relationship between different types of power in a three-phase system. The power triangle consists of three sides: real power, reactive power, and apparent power. Real power is the power that is actually used to perform useful work, whereas reactive power is the power required to create and maintain magnetic fields. Apparent power is the combination of both real and reactive power. The power triangle can be used to calculate the power factor and identify areas of inefficiency in the system. Discover how capacitive loads can be used to correct lagging power factor in three-phase distribution networks.

How do you calculate the line-to-line voltage and line-to-neutral voltage in a three-phase system?

The line-to-line voltage in a three-phase system is calculated by multiplying the line-to-neutral voltage by the square root of three. Likewise, the line-to-neutral voltage can be calculated by dividing the line-to-line voltage by the square root of three. These calculations consider that the voltage measured in a three-phase system is line-to-line, whereas it is line-to-neutral in a single-phase system.

Calculating three-phase power requires considering various factors, including voltage, current, and power factor. The 3-phase power formula is the key to understanding the relationship between these factors. By using this formula, you can determine the total power in a three-phase system, as well as the power in each individual phase.

Additionally, converting kW to amps is an essential calculation for three-phase power, as it helps determine the load that a particular system can handle. Understanding the power factor is also critical for three-phase power, as it can have a significant impact on system efficiency. With the right knowledge of phase power equations, you can ensure that your three-phase system is running optimally and safely.

Related Articles

Electrical Grounding Definition

Electrical grounding is the process of connecting electrical systems to the earth to ensure safety and stability. It protects people and equipment by redirecting excess electricity, such as lightning or electrical faults, into the ground, thereby reducing the risk of shock and fire hazards.

What is a good Electrical Grounding Definition?

Electrical Grounding is best described as a physical wiring path that provides a route for short-circuit current to flow to the earth in the event of a fault in the power system. Electrical grounding:

✅ Redirects excess electrical current safely into the earth

✅ Prevents electric shock, fires, and equipment damage

✅ Stabilizes voltage levels and improves circuit protection

A grounding and bonding system requires a physical connection between equipment and the earth, achieved through a ground rod driven into the ground.

Electrical grounding, also known as earthing, is a fundamental safety practice in all electrical systems. It involves connecting parts of the electrical circuit to the earth to protect people and equipment from electrical faults, surges, or lightning strikes. To explore the broader context of grounding in power systems, please visit our page on electrical grounding, which explains how it protects both people and equipment from electrical faults.

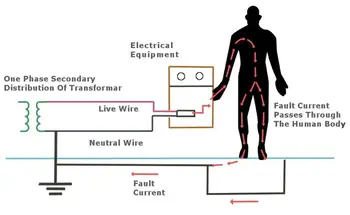

Industrial Electrical Grounding

Electricity in any industrial, commercial, institutional or residential wiring network is actually a flow of electrons moving through wires. This electricity flow is constantly seeking the shortest possible route to the earth. Hence, if there is a short circuit, the grounding and bonding system provides a direct route to the earth, rather than through people and equipment. The grounding and bonding system becomes a controlled pathway to earth, which is preferable to the current flowing through a person or piece of equipment, as it can be injurious and damaging. For a deeper look at code requirements, visit our detailed guide on electrical grounding code, which includes NEC and CEC standards.

In electrical installations, grounding conductors, such as the equipment grounding conductor (EGC) and the grounding electrode conductor (GEC), play a crucial role in establishing a safe path for fault current. Understanding the role of a grounding electrode conductor helps explain how fault currents are safely carried to earth in modern systems. These conductors connect non-current-carrying metal parts of electrical equipment to the grounding electrode, typically a ground rod or metal water pipe, ensuring a direct connection to the earth. This setup enables the safe redirection of any fault current from a short circuit, ground fault, or electrical surge away from people and sensitive equipment. A properly installed protective earth system minimizes the risk of electric shock and supports the overall integrity of the electrical distribution system. Learn how grounding and bonding work together to ensure electrical continuity and personnel safety in industrial and commercial facilities.

How does electrical grounding work?

In any electric power circuit, there is an active wire that supplies the power, a neutral wire that carries the current back, and a ‘grounding wire’ that provides an additional path for the current to return safely to the ground without causing danger to anyone in the event of a short circuit. The ground connection provides a path for electric current to flow, for instance, from a circuit breaker or electrical box through an electrical connection to a cold water pipe that extends into the earth, thereby assisting in dissipating energy into the actual ground. A reliable grounding system is essential for maintaining power quality and protecting sensitive electrical infrastructure.

The National Electrical Code and the Canadian Electrical Code provide guidelines to ensure the proper installation of ground wires in an electrical system, aiming to prevent potentially hazardous electric shock accidents. If you're unsure whether a facility is properly earthed, see our guide on how to check if an area is grounded for easy methods and safety tips.

Electrical Grounding Training Course Page

Grounding And Bonding Definitions (Article 100: National Electrical Code)

Bonded (Bonding). Connected to establish continuity and conductivity.

Bonding Conductor or Jumper. A reliable conductor to ensure the required conductivity between metal parts required to be electrically connected.

Bonding Jumper, Equipment. The connection between two or more portions of the equipment conductor.

Bonding Jumper, Main. The connection between the grounded circuit conductor and the equipment conductor at the service.

Bonding Jumper, System. The connection between the grounded circuit conductor and the supply-side bonding jumper, or the equipment grounding conductor, or both, at a separately derived system.

Ground. The earth.

Ground Fault. An unintentional, electrically conducting connection between an ungrounded conductor of an circuit and the normally non–current-carrying conductors, metallic enclosures, metallic raceways, metallic equipment, or earth.

Grounded (Grounding). Connected (connecting) to ground or to a conductive body that extends the ground connection.

Grounded, Solidly. Connected to ground without inserting any resistor or impedance device.

Grounded Conductor. A system or circuit conductor that is intentionally grounded.

Grounding Conductor, Equipment (EGC). The conductive path(s) installed to connect normally non-current-carrying metal parts of equipment together and to the system grounded conductor or to the electrode conductor, or both.

Grounding Electrode. A conducting object through which a direct connection to earth is established.

Grounding Electrode Conductor. A conductor used to connect the system grounded conductor or the equipment to an electrode or to a point on the electrode system.

Neutral Conductor. The conductor connected to the neutral point of a system that is intended to carry current under normal conditions.

Neutral Point. The common point on a wye-connection in a polyphase system or midpoint on a single-phase, 3-wire system, or midpoint of a single-phase portion of a 3-phase delta system, or a midpoint of a 3-wire, directcurrent system.

Separately Derived System. A premises wiring system whose power is derived from a source of electric energy or equipment other than a service. Such systems have no direct connection from circuit conductors of one system to circuit conductors of another system, except through connections made through the earth, metal enclosures, metallic raceways, or equipment conductors.

Ungrounded. Not connected to ground or to a conductive body that extends the ground connection.

Related Articles