IEC 61850 Protocol For Substations

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

IEC 61850 protocol enables fast, standardized communication between intelligent electronic devices (IEDs) in substations. It supports interoperability, real-time data exchange, and remote monitoring, making it vital for smart grid automation and modern power system protection.

What is IEC 61850 Protocol?

✅ Standardized communication for substation automation and control systems

✅ Enables interoperability between IEDs from different vendors

✅ Supports real-time monitoring, protection, and data exchange in smart grids

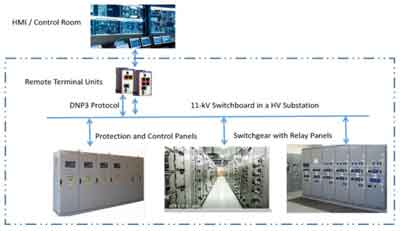

IEC 61850 is a communications protocol developed by the International Electrotechnical Commission (IEC) for substation automation systems. Unlike older legacy protocols that rely on fixed, vendor-specific formats, IEC 61850 uses an object-oriented data interoperability and abstract communication services to create a standardized method for data exchange among IEDs, SCADA system integration, and Human-Machine Interfaces (HMIs).

Its architecture is based on Ethernet and supports both client-server and peer-to-peer communications, making it ideal for smart grid applications that require high-speed, deterministic messaging. Explore how 3D substation design using AutoCAD can streamline planning for IEC 61850-based systems.

The IEC 61850 standard is an international standard defining the communication protocols used for intelligent electronic devices within electrical substations. Developed to support automation, this standard-defining framework enables interoperability and seamless data exchange between devices from different manufacturers. IEC 61850 is an international effort aimed at modernizing substation communications and improving reliability. One of its most innovative features is GOOSE (Generic Object-Oriented Substation Event) messaging, which facilitates high-speed, event-driven communication between devices without the need for a master controller. By standardizing these protocols, IEC 61850 plays a critical role in the development of secure, efficient, and future-ready power systems.

Key Features of the IEC 61850 Standard

-

Interoperability Across Devices

-

IEC 61850 enables seamless integration of equipment from multiple manufacturers by defining common data structures and naming conventions. This interoperability reduces engineering time and ensures long-term system flexibility.

-

-

High-Speed Messaging with GOOSE

-

The protocol includes GOOSE messaging (Generic Object-Oriented Substation Events), which allows IEDs to communicate critical event data in under 4 milliseconds. These peer-to-peer messages operate at the Ethernet layer, making them ideal for protection and control schemes.

-

-

Process Bus and Station Bus Architecture

-

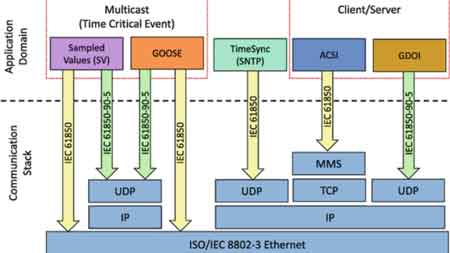

IEC 61850 divides communication into two logical layers:

-

Station Bus: Handles data exchange between IEDs, SCADA, and HMIs using MMS (Manufacturing Message Specification).

-

Process Bus: Replaces traditional copper wiring by transmitting sampled values (SV) and control signals between field equipment and IEDs over Ethernet via Merging Units (MUs).

-

-

-

Scalable Data Modeling

-

The standard uses Logical Nodes and Logical Devices to define all data points in a substation. This object-oriented modeling enables efficient configuration, simplified diagnostics, and faster system deployment.

-

-

Time Synchronization

-

IEC 61850 supports Precision Time Protocol (PTP) to align time-sensitive operations across devices, which is essential for fault analysis, event recording, and system coordination.

-

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Benefits of the GOOSE Messaging Protocol

The move toward IEC 61850-based systems brings significant advantages to utility operators and system integrators:

-

Reduced wiring complexity and installation costs

-

Improved protection system response through fast GOOSE messaging

-

Vendor-agnostic system design

-

Future-proofing with support for emerging smart grid technologies

-

Easier integration of renewable energy, energy storage, and microgrids

-

Enhanced cybersecurity through standards such as IEC 62351

See how RTU and HMI redundancy enhances system reliability within IEC 61850-enabled stations.

IEC 61850 Comparison Table

| Feature/Category | IEC 61850 | Legacy Protocols | Benefit of IEC 61850 |

|---|---|---|---|

| Communication Model | Ethernet-based, object-oriented, abstract services | Serial communication, vendor-specific formats | High-speed, scalable, and standardized communication |

| Messaging | GOOSE, MMS, Sampled Values (SV) | Modbus, DNP3, IEC 60870-5 | Real-time event handling and wide functionality |

| Device Interoperability | Multi-vendor interoperability via logical nodes and data models | Limited or no interoperability | Easier integration and future system upgrades |

| System Architecture | Station Bus and Process Bus architecture | Hardwired analog and digital signal routing | Reduced wiring, modular design, improved diagnostics |

| Time Synchronization | Precision Time Protocol (PTP/IEEE 1588) | Basic time stamping or GPS-based sync | Microsecond-level time accuracy for event correlation |

| Scalability | Fully scalable with support for DERs, virtual substations, and WAMS | Difficult to scale or integrate with modern systems | Future-proofed for smart grid expansion |

| Cybersecurity | Supports IEC 62351 security standards | Minimal built-in security features | Enhanced protection against cyber threats |

| Maintenance & Cost | Lower long-term costs, remote diagnostics, simplified updates | Higher installation/maintenance costs due to hardwiring | Operational savings and faster troubleshooting |

GOOSE Messaging: Real-Time Communication

GOOSE is one of the most critical innovations in the IEC 61850 protocol. It allows IEDs to send event-based messages without waiting for a master controller. These multicast messages can be received by any subscribed device on the network, enabling real-time fault isolation, breaker tripping, and interlocking logic.

For example, when a fault is detected by a protection relay, it can instantly broadcast a GOOSE message that trips nearby circuit breakers—within 4 milliseconds—minimizing damage and improving system stability.

Process Bus vs. Station Bus: Streamlining Substation Design

The protocol’s support for both station bus and process bus enables a more modular and efficient substation design:

-

The station bus handles monitoring, metering, and supervisory control via MMS messages.

-

The process bus connects high-voltage equipment to IEDs using digitized sampled values, eliminating the need for complex analog cabling.

This separation reduces installation and maintenance costs while improving measurement accuracy and enabling remote diagnostics. Understand the importance of substation accessibility when upgrading legacy systems to smart grid standards.

Future-Proofing Substations with IEC 61850

The IEC 61850 protocol is designed with scalability in mind. Its object-oriented structure allows new devices and functions to be added without major system reengineering. This makes it ideal for:

-

Integrating distributed energy resources (DERs)

-

Supporting wide-area monitoring systems (WAMS)

-

Enabling edge-based protection and control

IEC 61850 also facilitates the development of virtual substations, where protection and control functions can be virtualized, improving flexibility and reducing hardware dependency. For safe operations alongside modern protocols, review our 6 Basic Rules to Ensure Substation Safety.

Conclusion

The IEC 61850 protocol is the cornerstone of modern substation automation, providing a robust, interoperable, and future-ready platform for intelligent grid operations. With features like GOOSE messaging, process bus architecture, and standardized data models, it enables faster fault response, reduced engineering effort, and seamless integration of diverse systems.

As the power grid evolves to accommodate renewable energy, electrification, and decentralization, IEC 61850 remains essential to building safe, smart, and scalable digital substations.

Related Articles