Flywheel Energy Storage vs. Other Technologies

By R.W. Hurst, Editor

Battery Energy Storage Testing and Maintenance for Solar PV Systems

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Flywheel energy storage systems store kinetic energy in rotating mass to deliver rapid response, improve grid stability, and support renewable integration with high efficiency, reliability, long cycle life, low environmental impact, and sustainable performance.

What is Flywheel Energy Storage?

Flywheel energy storage (FES) is a mechanical system that stores energy in a rotating mass to deliver electricity quickly and efficiently.

✅ Provides rapid response for grid stability and renewable integration

✅ Offers long cycle life with minimal maintenance needs

✅ Enhances energy efficiency and reduces environmental impact

Flywheel energy storage is a promising technology for energy storage with several advantages over other energy storage technologies. Flywheels are efficient, have a longer lifespan, and can provide fast response times to changes in power demand. In addition, Flywheel systems have numerous applications, including grid stabilization, backup power, and UPS systems. While FES is still in the development and commercialization stage, ongoing research and development are expected to lead to further technological improvements, making it a more competitive option in the global energy mix.

Energy Storage Systems Training

How Does Flywheel Energy Storage Work?

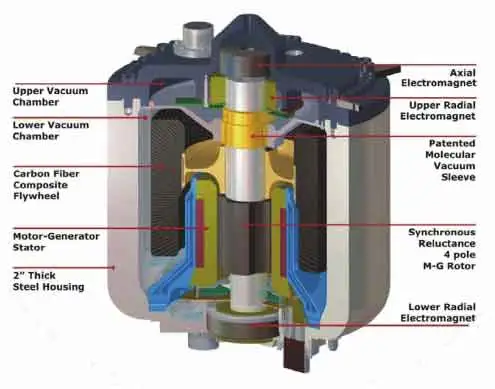

FES works by converting electrical energy into kinetic energy stored in a high-speed rotor. A typical system includes a flywheel rotor made of steel or advanced composites, housed in a vacuum enclosure to minimize air drag. Bearings—mechanical, magnetic, or superconducting—support the rotor and reduce friction. Power electronics connect the flywheel to the grid or local load.

When electricity is supplied, the motor accelerates the rotor, storing energy as rotational kinetic energy. When electricity is required, the generator decelerates the rotor, converting the kinetic energy back into electrical energy. Magnetic and superconducting bearings, along with vacuum containment, help minimize losses and extend operational life.

Sign Up for Electricity Forum’s Energy Storage Newsletter

Stay informed with our FREE Energy Storage Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Energy storage capacity is often measured in watt-hours per kilogram (Wh/kg), while response speed and round-trip efficiency (typically 70–90%) make flywheels competitive for short-duration, high-power applications.

Advantages and Disadvantages

One of the primary advantages of flywheels is their ability to respond almost instantly to fluctuations in power demand. Their long cycle life—often exceeding two decades—makes them sustainable compared to chemical batteries. Flywheels also exhibit minimal degradation over thousands of charge-discharge cycles and support ancillary services like frequency regulation.

However, challenges remain. Frictional and standby losses can reduce stored energy over time, even in vacuum-sealed systems. High rotational speeds demand strong, lightweight rotor materials such as carbon fiber composites, which increase manufacturing costs. Safety containment is crucial for handling potential rotor failure under extreme stress, which adds complexity and cost.

Flywheel Energy Storage Applications

Flywheel systems have been deployed across multiple sectors:

-

Grid Stabilization: Flywheels provide frequency regulation and voltage support, responding to demand spikes in milliseconds. Beacon Power has operated flywheel plants in the U.S. for grid ancillary services.

-

Backup Power and UPS Systems: In data centers, hospitals, and industrial facilities, flywheels serve as reliable, fast-response UPS solutions, reducing reliance on chemical batteries.

-

Transportation and Aerospace: Compact flywheel systems have been tested for buses, trains, and aircraft to recover braking energy and reduce fuel use.

-

Microgrids and Renewables Integration: Flywheels smooth variability from wind and solar power, stabilizing hybrid systems in remote or island grids.

Benchmarking Flywheel vs Other Energy Storage Technologies

| Technology | Energy Density (Wh/kg) | Cycle Life | Response Time | Typical Applications |

|---|---|---|---|---|

| Flywheel | 20–80 | >20 years, >100k | Milliseconds | Grid stability, UPS, short bursts |

| Lithium-ion Battery | 100–250 | 5–15 years | Seconds | EVs, portable electronics, grid storage |

| Supercapacitor | 5–10 | >1M cycles | Milliseconds | Power quality, regenerative braking |

| Pumped Hydro | 0.5–1 | 30–60 years | Minutes | Bulk, long-duration energy storage |

| Compressed Air | 2–6 | 20–40 years | Minutes | Grid-scale long-term storage |

This comparison highlights where flywheels excel: ultra-fast response, long cycle life, and high power density, but lower energy density than batteries or hydro.

Efficiency and Performance

Flywheel systems typically achieve round-trip efficiencies of 70–90%. Losses occur from friction, magnetic drag, and electrical conversion. Unlike chemical batteries, flywheels self-discharge more quickly, making them better suited for short-term storage rather than long-duration energy shifting.

Still, their high power density, fast ramp rate, and low lifecycle cost per cycle make them ideal for applications needing immediate power injection.

Market Outlook and Adoption

The global FES market is expanding, projected to grow from USD 351.94 million in 2025 to USD 564.91 million by 2032, at a CAGR of nearly 7% (Fortune Business Insights).

Leading companies such as Beacon Power, Amber Kinetics, and Temporal Power have demonstrated commercial-scale flywheel projects for grid regulation and UPS. While adoption lags behind batteries, niche markets like microgrids, critical facilities, and renewable integration are driving growth.

Challenges include high upfront costs, rotor safety concerns, and competition from falling battery prices. However, ongoing research is improving rotor materials, reducing friction losses, and lowering costs.

Future Trends and Research Directions

Flywheel development continues to advance with several key innovations:

-

Advanced Bearings: Active magnetic and superconducting bearings reduce friction and extend operational life.

-

Composite Rotors: High-strength carbon fiber improves energy density while reducing rotor mass.

-

Hybrid Systems: Integration with batteries or supercapacitors creates systems that combine high energy and high power.

-

Scalability and Modularization: Modular flywheels for microgrids and distributed energy resources are under active development.

-

Sustainability: Unlike chemical batteries, flywheels contain no toxic materials and are fully recyclable, making them attractive for green infrastructure.

Challenges and Limitations

Despite their advantages, flywheels face challenges in adoption. High-speed rotation requires costly materials and precision engineering. Safety containment must be robust to prevent catastrophic failure. Standby losses limit long-duration storage applications. Regulatory standards and market structures also influence their competitiveness compared to established technologies, such as lithium-ion.

Addressing these barriers is crucial for the broader adoption of energy storage in global markets.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Frequently Asked Questions

How long can a flywheel store energy?

Typically from seconds to several hours, depending on rotor design, size, and bearing technology. They are most efficient for short-duration, high-power applications.

What limits flywheel energy storage?

The strength of the rotor material, frictional losses, and the cost of high-speed composite rotors are the primary limiting factors.

Is flywheel storage better than batteries?

For short-term, high-power needs and frequent cycling, yes. For long-duration storage, batteries are typically more practical.

What is the efficiency of flywheels?

Round-trip efficiency ranges between 70–90%, with losses from bearings, vacuum drag, and electrical conversion.

Where are flywheels used today?

They are deployed in grid stabilization plants, UPS systems for data centers and hospitals, microgrids, and experimental transport systems.

Related Articles