Hipot Testing Explained

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Hipot testing checks electrical insulation strength by applying high voltage to confirm there are no current leaks. It is essential for ensuring safety, detecting faults, and preventing electrical failures in power equipment, cables, transformers, and other high-voltage systems.

What is Hipot Testing?

Hipot testing is a critical procedure for evaluating the dielectric strength and insulation integrity of electrical systems.

✅ Detects insulation breakdowns and leakage currents.

✅ Ensures equipment safety and compliance with standards.

✅ Prevents electrical hazards in high-voltage systems.

Also known as dielectric withstand, hipot testing applies high voltage to confirm that insulation can endure operating and surge conditions without breaking down. This test is crucial across various industries, including medical devices, automotive electronics, and aerospace systems, where insulation failure can pose life-threatening hazards. Companies that fail to conduct a proper dielectric strength test risk product recalls, lawsuits, and reputational damage, while effective analysis ensures reliability and safety.

A comprehensive dielectric strength evaluation is essential to ensure electrical insulation can withstand high voltages without failure. During hipot evaluations, engineers closely monitor the leakage current limit to detect any early signs of insulation breakdown. Complementary procedures like the insulation resistance inspection verify the long-term reliability of insulating materials, while partial discharge measurement helps identify microscopic defects that may develop into serious faults under stress. Additionally, performing a ground bond measurement ensures that all conductive paths can safely carry fault currents, completing a robust safety and quality assurance process.

Hipot Testing and Dielectric Withstand Test

Hipot testing, also known as a dielectric withstand test, is a method used to verify the electrical insulation strength of a device or component. The term “dielectric” refers to an insulating material’s ability to resist the flow of electric current, while “withstand” indicates the material’s capacity to endure high voltage without breaking down. During this test, a voltage much higher than the device’s normal operating level is applied between the conductive parts and the insulation. The goal is to ensure that the insulation can safely block current flow, preventing electrical shock, equipment damage, or catastrophic failures.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

In practice, the dielectric withstand test checks for:

-

Leakage current: Measuring if any unwanted current flows through insulation when exposed to high voltage.

-

Breakdown point: Identifying the voltage level at which insulation fails or starts conducting.

-

Safety margins: Confirming the insulation can withstand voltage spikes far above normal operating conditions.

This test is essential in industries like medical, automotive, and aerospace, where insulation integrity directly impacts safety and reliability.

The Importance of Hipot Testing

Hipot testing is a cornerstone of electrical safety, particularly in industries where failure is not an option. In medical devices, patient safety is paramount—any breakdown in insulation resistance could lead to electrical shock or malfunctions during critical procedures. The same applies to automotive and aerospace systems, which must perform reliably under extreme conditions. High-voltage tests conducted during production ensure that every device meets rigorous safety standards before it reaches the field. Neglecting this step can result in product recalls, lawsuits, or catastrophic failures, both financially and ethically.

There are three primary hypot test methods:

-

AC test applies alternating current, which can expose insulation weaknesses that occur under dynamic voltage conditions.

-

DC test uses direct current and is effective for identifying leakage currents and insulation resistance over time.

-

Impulse test simulates sudden, transient voltage spikes to assess how components withstand extreme surges.

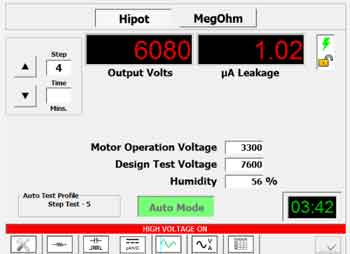

The examination process consists of three stages: preparation, examination, and analysis. It starts with ground bond tests to verify that the grounding path can safely handle fault currents. Once verified, the device under test is connected to a hipot tester, and the required voltage is applied for a set duration. During this period, leakage current is closely monitored, and any readings above acceptable limits indicate insulation failure or degradation.

Modern automated hipot testers have transformed the process, enabling the simultaneous examination of multiple devices, reducing human error, and accelerating production lines. These systems can store data for analysis, enabling trend monitoring and preventive maintenance. Equally important is the regular calibration and maintenance of the test equipment itself, as inaccurate or poorly maintained testers can lead to false pass/fail results, compromising both product quality and safety.

Hipot Test Types – Comparison Table

| Test Type | Description | Applications | Advantages/Limitations |

|---|---|---|---|

| AC Hipot Test | Applies alternating current at high voltage to the DUT | Common for transformers, cables, and general devices | Detects weaknesses under dynamic voltage but can stress capacitive loads |

| DC Hipot Test | Uses direct current to check insulation integrity | Ideal for capacitive loads like cables and motors | Easier leakage measurement but may not reveal AC-related weaknesses |

| Impulse Test | Simulates transient high-voltage spikes (surges) | Aerospace, automotive, and lightning surge test | Closest to real surge conditions but highly specialized |

Voltage Levels and Test Duration

Determining the correct test voltage and duration is crucial for accurate dielectric withstand.

Standard Formula:

Test Voltage ≈ 2 × Operating Voltage + 1,000 V

For instance, a product rated at 480 V would typically be tested at:

(2 × 480) + 1,000 = 1,960 V.

Typical test durations:

-

Design tests (prototype/certification): ~1 minute for thorough insulation verification.

-

Production tests (quality checks): ~1 second for efficient, large-scale assessment while maintaining safety.

These parameters ensure that insulation can endure unexpected surges without damaging the device or compromising user safety.

Safety Considerations and Leakage Current Thresholds

Hipot testing involves high voltages, making the safety of both operators and equipment a top priority. Test setups must minimize the risk of electric shock or equipment damage.

Key safety practices:

-

Grounding design: Properly ground all exposed conductive parts to divert fault current.

-

Current limits: Keep total current limits as low as possible, typically between 0.1 mA and 20 mA, depending on the standard.

-

Safe fixtures: Use enclosures, interlocks, and warning indicators to prevent accidental contact.

-

Tester maintenance: Regular calibration ensures accurate readings and avoids false results.

In addition to dielectric strength tests, engineers often conduct insulation resistance tests and ground bond tests to confirm the existence of safe conductive paths. For high-voltage applications, partial discharge measurement is used to detect microscopic insulation defects that standard hipot testing may not reveal.

Sign Up for Electricity Forum’s T&D Test Equipment Newsletter

Stay informed with our FREE T&D Test Equipment Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Interpreting Hipot Test Results

Interpreting the results of a high-potential test requires technical insight, as even minor deviations can have significant implications. A common challenge is understanding the measurements of leakage current. While some leakage is acceptable, excessive current indicates insulation breakdown, which can compromise electrical safety. Accurate analysis of these results requires experience and technical expertise. Production lines often use statistical process control (SPC) to monitor these results over time, ensuring consistency and identifying trends that may signal a developing problem. A clear interpretation of these test reports enables timely corrective action, minimizing disruptions to the production line.

Standards and Regulatory Compliance in Hipot Testing

Hipot testing must align with global standards to guarantee product safety and certification.

Key standards include:

-

IEC 60950: High-voltage evaluation for IT and communication equipment.

-

IEC 61010: Safety protocols for industrial, laboratory, and control equipment.

-

UL and CSA: North American standards that require a dielectric strength test for certification.

-

Partial discharge test: Used alongside hipot tests in power systems and transformer industries for detecting latent insulation weaknesses.

Adhering to these standards ensures compliance with legal requirements, enhances market acceptance, and protects manufacturers from liability.

The Future of Hipot Testing: Automation, AI & Predictive Maintenance

Emerging technologies are transforming dielectric strength test (hipot testing), making it more efficient, accurate, and safe. Automated test systems now reduce human error, streamline production line integration, and provide real-time data analytics for improved fault detection. The next wave of innovation includes integrating AI and machine learning to analyze large test datasets and predict insulation failures before they occur, enabling predictive maintenance and continuous quality assurance. Remote measurement capabilities—such as PLC-controlled testers and even drone-equipped systems—are expanding access to examination in hazardous or remote environments while minimizing operator exposure to high voltage. Companies adopting these modern approaches stay ahead of evolving safety mandates and deliver reliable, future-ready inspection solutions.

Frequently Asked Questions

What is the meaning of hipot?

Hipot, short for “high potential,” is a high-voltage safety test that verifies the insulation strength of electrical devices, ensuring they can withstand surges and prevent leakage current.

How is a hipot test done?

A device under test is connected to a tester that applies AC, DC, or impulse voltage between conductive parts and insulation. Leakage current is measured, and any excessive value indicates a failure.

What is a hipot failure?

A failure occurs when insulation cannot withstand the applied voltage, resulting in high leakage current or breakdown, which could lead to electrical shocks or equipment malfunctions.

Is the hipot test AC or DC?

Hipot testing can be performed with either AC or DC voltage. AC tests reveal weaknesses under fluctuating conditions, while DC tests are preferred for stable, capacitive loads.

Related Articles