Why Electrical Testing and Maintenance Matters

Electrical Maintenance Training teaches professionals how to inspect, test, and repair electrical equipment and systems. Learn predictive maintenance, troubleshooting, and safety practices to improve reliability, performance, and compliance in industrial and commercial facilities.

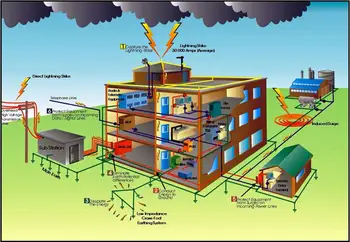

- Protects workers from life-threatening hazards

- Helps employers meet NFPA 70E and CSA Z462 regulatory requirements

- Teaches hazard recognition, proper PPE use, and safe work practices

- Reduces legal, financial, and operational risks for organizations

Certified Electrical Testing and Maintenance

- Ensure compliance with NFPA 70E and CSA Z462 Workplace Electrical Safety standards.

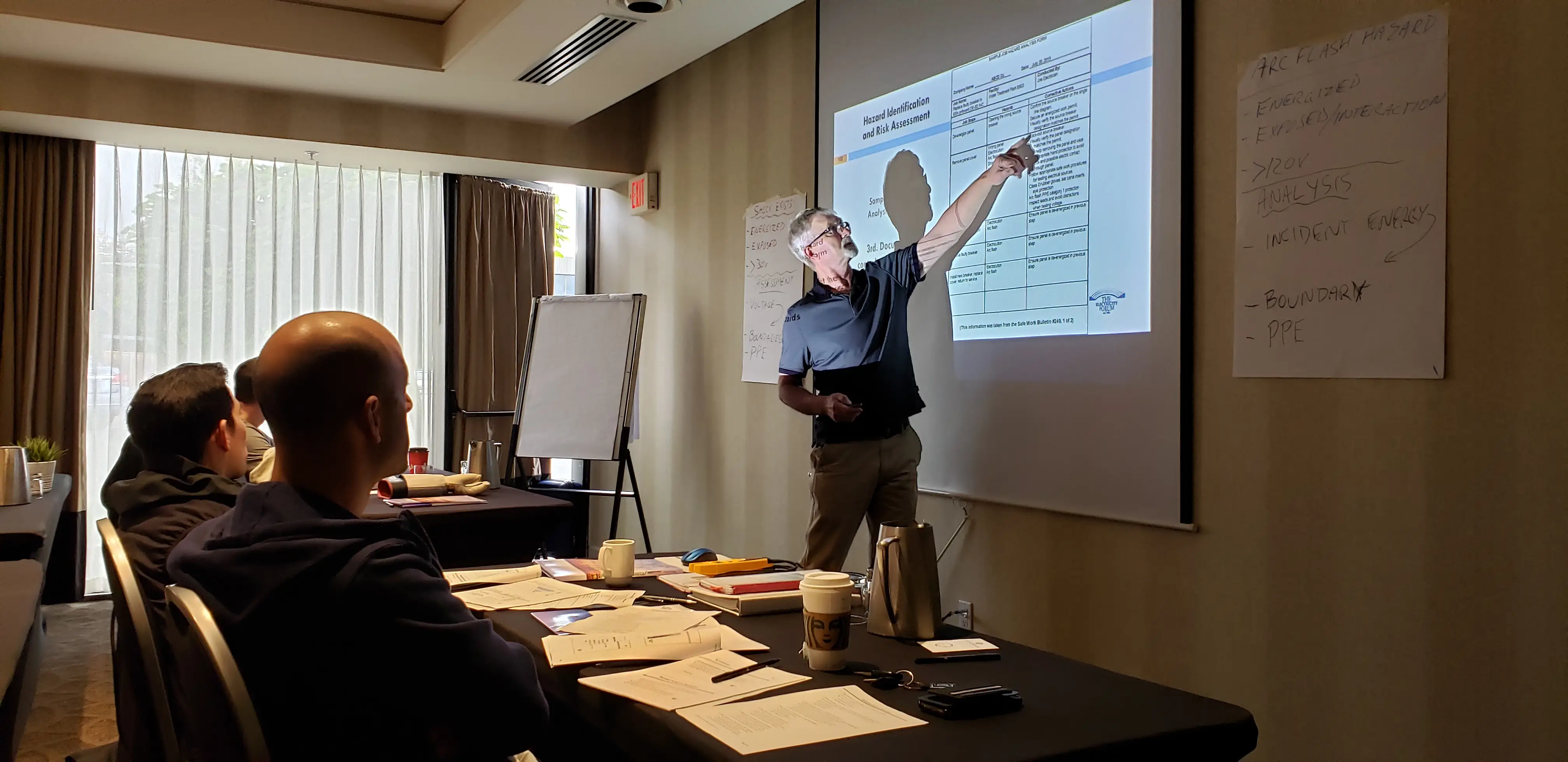

- Provide practical instruction for both qualified electrical workers and non-electrical personnel.

- Protect employees and reduce downtime through effective hazard prevention and mitigation education.

Explore EF Training Subjects

Arc Flash Electrical Safety Courses

Circuit Breaker Maintenance Training

Circuit Breaker Maintenance Training Course - Upgrade Your Skills Today! - The Electricity Forum Training Institute

Electrical Testing & Commissioning of Power Systems

Electrical Commissioning Training - This 12-Hour live online instructor led course covers practices and procedures that are essential to the safe start up of any Industrial, Commercial and Institutional power system.

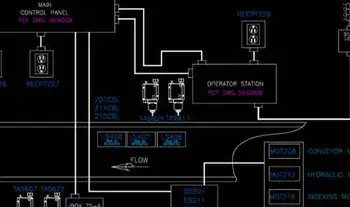

Electrical Troubleshooting Training

Electrical Troubleshooting Training - Our 12-hour live online course teaches how important it is to establishing a preventative maintenance program. The most important thing is to maintain the uptime of equipment and reduce planned and unplanned downtime.

High Voltage Maintenance Training Online

High Voltage Maintenance Training Online - Our 12-hour (2-Day) instructor-led course covers and exceeds provincial and federal electrical safety requirements for working on electrical equipment that is 750V or greater.

MV & HV Circuit Breaker Maintenance Training

Medium & High Voltage Circuit Breaker Maintenance - This 12-hour (2 Day) live online training course is designed for engineers and technicians who participate in the design, installation, testing, or maintenance of HV circuit breakers and substation controls.

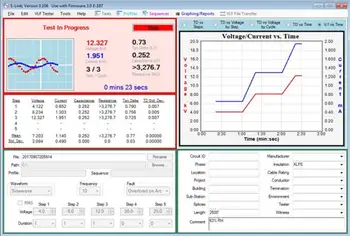

Medium Voltage Cable Testing Training

Medium Voltage Cable Testing Training covers VLF, Tan Delta, and Partial Discharge testing to ensure cable reliability and condition-based maintenance.

Electrical Testing and Maintenance Certification and CEU Credits

- Our Electrical Testing and Maintenance courses are recognized for Continuing Education Units (CEUs) and Professional Development Hours (PDHs).

- Delivered by industry-certified instructors with decades of field experience.

- Training meets or exceeds OSHA, NFPA, and CSA requirements.

Recognized by