Minimum Approach Distance Chart

By R.W. Hurst, Editor

NFPA 70e Training - Arc Flash

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

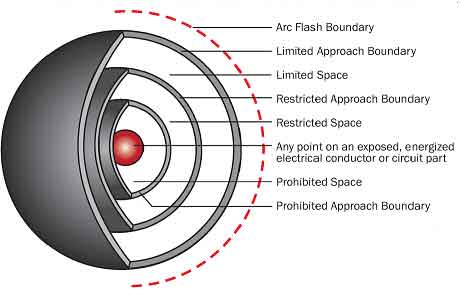

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

The minimum approach distance chart defines safe working distances to prevent arc flash injuries. Based on NFPA 70E and OSHA standards, it helps protect electrical workers by specifying limits by voltage level.

What is a minimum approach distance chart?

It is a critical tool that outlines the safe distances workers must maintain when working near energized electrical conductors or equipment. These distances, established by regulatory bodies such as OSHA, vary based on the system's voltage level and are designed to protect workers from electrical hazards.

✅ Defines Safe Distances: Specifies how close workers can get to energized equipment based on voltage levels.

✅ Based on Standards: Follows NFPA 70E, OSHA, and CSA guidelines for arc flash and shock protection.

✅ Protects Workers: Helps prevent electrical injuries by guiding proper approach limits for qualified and unqualified personnel.

For instance, OSHA's Table R-6 specifies minimum approach distances for various voltage ranges, ensuring workers adhere to safe practices when operating near live electrical parts. This chart guides how close workers can safely get to energized equipment based on system voltages and other factors, ensuring compliance with safety standards such as NFPA 70E. Maintaining a safe working distance from energized parts in electric power systems is critical to preventing electrical hazards.

Visit Our NFPA 70E Training Course

Visit Our Our CSA Z462 Training Course

Understanding and utilizing the minimum approach distance chart is essential for compliance with electrical safety standards and for safeguarding personnel against potential electrical shocks and arc flashes. Employers are responsible for ensuring that all workers are trained to recognize these distances and implement appropriate safety measures when working near energized components.

How is the Minimum Approach Distance Chart Determined?

The chart is developed through engineering analysis of various factors, including the phase-to-ground and phase-to-phase system voltages. Phase-to-ground voltage refers to the voltage difference between an energized conductor and the ground, while phase-to-phase system voltage represents the voltage difference between two energized conductors. Both of these voltages are considered when calculating the required separation distances.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Transient overvoltage is also a critical factor in determining these distances. Engineering analysis helps estimate the potential magnitude of transient events, ensuring that the minimum approach distances take these spikes into account. In environments with higher potential for transient overvoltage, greater separation distances are required to protect workers.

It is also influenced by environmental factors such as humidity, temperature, and altitude. These factors can affect the behavior of electrical systems and, therefore, influence the necessary distances for safe operation.

Example: Minimum Approach Distance (MAD) Chart

| Voltage to Ground (Phase-to-Ground) | Unqualified Worker Distance | Qualified Worker MAD |

|---|---|---|

| 0 – 50 V | Not specified (Avoid contact) | Avoid contact |

| 51 – 300 V | 3 ft 6 in (1.07 m) | 1 ft 0 in (0.30 m) |

| 301 – 750 V | 3 ft 6 in (1.07 m) | 1 ft 6 in (0.46 m) |

| 751 – 15 kV | Not permitted | 2 ft 1 in (0.64 m) |

| 15.1 – 36 kV | Not permitted | 2 ft 7 in (0.79 m) |

| 36.1 – 46 kV | Not permitted | 2 ft 10 in (0.86 m) |

| 46.1 – 72.5 kV | Not permitted | 3 ft 6 in (1.07 m) |

| 72.6 – 121 kV | Not permitted | 3 ft 9 in (1.14 m) |

| 138 – 145 kV | Not permitted | 4 ft 3 in (1.30 m) |

Minimum Approach Distance Chart and NFPA 70E Compliance

The NFPA 70E standard for electrical safety in the workplace outlines the requirements for safe work practices when dealing with energized equipment. The chart is a crucial component of this standard, ensuring workers maintain appropriate distances from electrical hazards. Compliance with NFPA 70E is essential for preventing accidents and protecting workers and equipment.

NFPA 70E defines safe working practices, including using personal protective equipment (PPE) and establishing safety zones around energized parts. The chart determines these safety zones, ensuring that workers do not come too close to live electrical components without the necessary precautions in place.

The chart helps employers comply with NFPA 70E and is also essential for meeting Occupational Safety and Health Administration (OSHA) requirements. OSHA mandates that employers provide a safe working environment; the chart is a key tool for ensuring compliance with this mandate.

U.S. vs. Canadian Standards for Overhead Power Line Safety

In the United States, Minimum Approach Distances (MAD) are regulated primarily under OSHA 29 CFR 1910.269 for electric power generation, transmission, and distribution work, and 29 CFR 1926 Subpart V for construction. The required approach distances vary based on:

-

Voltage level

-

Whether the worker is “qualified” or “unqualified”

-

Conditions such as altitude and insulation

Qualified Workers

Here’s a simplified summary for qualified workers at sea level under standard conditions:

| Operating voltage between conductors of an overhead power line | Safe limit of approach distance for persons and equipment |

| Voltage Range (Phase-to-Ground) | MAD (Qualified Worker) |

|---|---|

| 0 – 50 V | Avoid contact |

| 51 – 300 V | 1 ft 0 in (0.30 m) |

| 301 – 750 V | 1 ft 6 in (0.46 m) |

| 751 V – 15 kV | 2 ft 1 in (0.64 m) |

| 15.1 – 36 kV | 2 ft 7 in (0.79 m) |

| 36.1 – 46 kV | 2 ft 10 in (0.86 m) |

| 46.1 – 72.5 kV | 3 ft 6 in (1.07 m) |

| 72.6 – 121 kV | 3 ft 9 in (1.14 m) |

| 138 – 145 kV | 4 ft 3 in (1.30 m) |

| 161 – 169 kV | 4 ft 9 in (1.45 m) |

| 230 – 242 kV | 5 ft 8 in (1.73 m) |

| 345 – 362 kV | 7 ft 6 in (2.29 m) |

| 500 – 550 kV | 11 ft 0 in (3.35 m) |

| 765 – 800 kV | 15 ft 4 in (4.67 m) |

For Unqualified Workers:

-

OSHA 29 CFR 1910.333(c)(3) requires a minimum distance of 10 feet (3.05 m) from overhead lines under 50 kV, and an additional 4 inches for every 10 kV over 50 kV.

Frequently Asked Questions

Why is it Important for Electrical Safety?

It outlines the safe distance workers must maintain when working near energized parts. These distances are designed to protect workers from the risks of electrical shock, arc flashes, and other hazards that can occur when working with high-voltage equipment. The chart is particularly crucial for workers involved in transmission and distribution operations, where the potential for electrical hazards is high due to the system voltages present.

In addition to reducing the risk of direct contact with energized parts, the chart considers potential transient overvoltage events, which can increase the risk of electrical incidents. Transient overvoltage occurs when the voltage in a system suddenly spikes due to factors such as switching operations or lightning strikes. Workers can avoid these potentially life-threatening events by ensuring a safe approach distance.

How Does the MAD Chart Change with Different Voltages?

The distances specified in the chart vary depending on the phase-to-ground and phase-to-phase system voltages. The required distance from energized parts increases as the system voltage increases. For example, the separation required for systems operating at 15 kV will be significantly smaller than the distance required for systems operating at 345 kV or higher.

In lower voltage systems, the risks associated with transient overvoltage are also smaller, meaning the required distances are shorter. However, in high-voltage transmission systems, where the potential for overvoltage events is greater, workers must maintain larger distances to ensure safety.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Another factor influencing the required distances is the equipment’s insulation level. Well-insulated equipment may allow for shorter separation distances, while poorly insulated or uninsulated components require greater distances to avoid electrical hazards.

What PPE is Required?

Personal protective equipment (PPE) is essential for protecting workers operating within the approach distances outlined in the chart. PPE requirements are typically defined by the incident energy levels and the system voltage workers are dealing with. For example, workers near energized parts at lower voltages might only need basic arc-rated clothing and gloves, while workers dealing with high-voltage systems may require full flash suits, insulated tools, and protective face shields.

Additionally, workers should be trained to use PPE to ensure maximum protection. This includes understanding when PPE must be worn, how to inspect PPE for damage, and how to use it properly while working near energized parts.

At higher voltages, the PPE required becomes more extensive due to the increased risk of arc flashes and other electrical hazards. Full-body protection is often necessary for transmission and distribution systems to ensure that workers are not exposed to dangerous incident energy levels.

The minimum approach distance chart is a critical tool for ensuring the safety of workers in electric power systems, particularly in transmission and distribution environments. By defining safe distances based on phase-to-ground and phase-to-phase system voltages and considering factors like transient overvoltage, the chart helps protect workers from electrical hazards. Compliance with NFPA 70E and the proper use of PPE are essential for maintaining a safe working environment when dealing with energized parts. Understanding and applying the guidance is key to preventing accidents and ensuring electrical safety.