Phase Rotation Meter

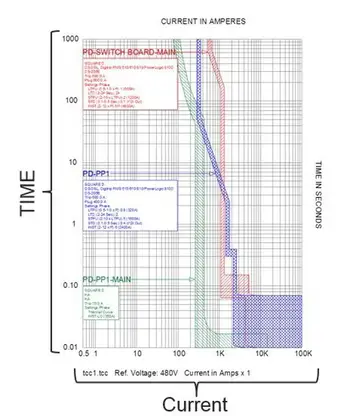

Short Circuit Study & Protective Device Coordination

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

A phase rotation meter determines the sequence of three-phase electrical systems, ensuring correct motor connections and preventing damage to the system. It verifies phase sequence, detects wiring errors, and improves safety in industrial, commercial, and utility power applications.

What is a Phase Rotation Meter?

A phase rotation meter is an indispensable tool for industrial electricians. It ensures the correct sequence in three-phase power systems, preventing potential damage to motors, transformers, and other critical equipment.

✅ Identifies the correct sequence of three-phase power systems.

✅ Prevents motor damage by ensuring proper rotation direction.

✅ Detects wiring faults and improves system reliability.

Power System Fundamentals Training

Short Circuit Study & Protective Device Coordination Training

Arc Flash Analysis/Study Training

By understanding how to use this device, you can guarantee the safety and efficiency of your electrical installations. These systems are widely used in industrial applications because they provide a stable and efficient power supply. The term phase rotation refers to the order in which the phases of an electrical system reach their peak values. This sequence is critical for devices like motors, as it determines the direction in which they rotate. Incorrect phase rotation can result in reverse motor operation, potentially damaging equipment and halting production. A rotational phase tester is specifically designed to detect and indicate the phase sequence, ensuring that systems are installed correctly and function safely. It is a vital tool in electrical engineering, ensuring the proper phase sequence and safe operation of motors and transformers.

Functionality

The role of this meter is straightforward yet vital. By connecting its test leads to the three conductors of a system, the device measures the sequence of the electrical phases. Many modern meters display results through intuitive interfaces, making them user-friendly even for those less experienced. The ability to verify a sequence quickly and accurately minimizes downtime during installations and troubleshooting. Understanding phase rotation is closely related to load flow analysis, which evaluates power distribution and system performance.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Comparison of Phase Rotation Meters and Other Testing Devices

| Device Type | Primary Function | Advantages | Limitations |

|---|---|---|---|

| Phase Rotation Meter | Determines the three-phase sequence | Quick, accurate phase sequence detection | Limited to phase rotation checks |

| Digital Multimeter | Measures voltage, current, and resistance | Versatile, widely available | Cannot directly detect phase rotation |

| Oscilloscope | Visualizes waveforms and signal timing | Detailed phase and signal analysis | Expensive and requires technical skill |

| Clamp Meter | Measures current flow without breaking the circuit | Easy to use for current measurements | Does not indicate phase sequence |

Addressing Starting Current Challenges

A critical aspect of using equipment is managing the starting current or inrush current. This surge of electricity occurs when devices like motors or transformers are first activated, and it can trip circuit breakers if not properly managed. Understanding the relationship between phase sequence and starting current is essential for maintaining system stability. Properly using tools like devices helps mitigate issues caused by these initial electrical surges. Industrial electricians often use this device in conjunction with power system analysis and design to ensure optimal motor connections.

Frequently Asked Questions

What does it do?

It is a specialized electrical testing device used to determine the direction of the rotating magnetic field in a three-phase electrical system. It identifies the sequence in which the three phases (L1, L2, L3) are arranged, which is crucial for ensuring proper motor rotation and the safe operation of equipment. Proper rotation is crucial for motors, generators, and other rotating equipment, as incorrect rotation can lead to malfunction or mechanical damage. Proper sequence verification is a key concept in power system engineering, helping prevent costly equipment failures.

What are the common applications?

From manufacturing plants to HVAC systems, the applications of testers are vast. These devices are particularly crucial when installing or maintaining machinery reliant on three-phase power, such as industrial compressors and large-scale motors. These machines could operate inefficiently or sustain permanent damage without first confirming the rotation. Additionally, they are widely used in power distribution to verify proper connections between transformers and load equipment.

How do you calculate phase rotation?

It is not "calculated" in a mathematical sense but is rather "measured" or "determined" using a rotation meter or an oscilloscope. Here’s how you determine phase rotation:

Use a Meter:

-

Connect the three test probes of the meter to the conductors (L1, L2, L3) of the system.

-

Turn on the device.

-

The meter will display the sequence as either "ABC" (positive rotation) or "CBA" (negative rotation).

Using an Oscilloscope (Manual Method):

-

Connect the oscilloscope probes to the three phases.

-

Observe the waveform

-

The order in which the waveforms cross zero from negative to positive indicates the rotation.

-

Label the order as ABC or CBA, depending on the sequence.

How to test phase rotation with a multimeter?

A standard digital multimeter (DMM) cannot directly measure rotation, as it lacks the capability to detect the sequence. However, you can indirectly check rotation using the following method:

Identify the Phases:

- Identify the three-phase wires L1, L2, and L3.

Voltage Measurements:

- Measure the voltage between L1 and L2, L2 and L3, and L3 and L1 using the multimeter.

- Note the values. In a balanced system, the voltages should be equal.

Compare Relative Voltages:

- If you have access to two separate points (like motor terminals), turn on the motor and observe its direction of rotation.

- If the motor rotates in the opposite direction of what is intended, the rotation is incorrect, and you should swap two of the three-phase connections (like L1 and L2).

Since a multimeter cannot detect the order of the voltages, it is recommended to use a meter for this task.

How to Check the Phase Sequence with a Meter?

To check the sequence, follow these steps:

Turn Off Power: Ensure the system is de-energized before connecting the meter.

Connect the Meter Probes:

- Attach the meter's probes to the three phases (L1, L2, and L3).

- Ensure the probes are properly connected to avoid false readings.

Test Your Knowledge About Electrical Engineering!

Think you know Electrical Engineering? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Turn On Power:

- Energize the system.

Check the Display:

- The meter will display the sequence as either ABC (positive sequence) or CBA (negative sequence).

- Some meters have indicator lights or arrows to show the direction.

Interpret the Results:

- If the sequence is incorrect, it can be corrected by swapping two conductors (such as L1 and L2) to change the rotation.

These steps ensure the proper functioning of motors and other equipment that rely on specific rotation for normal operation.

Electricians can enhance their skills with specialized power system training, which often includes hands-on use of rotation meters and testing tools.

Related Articles