Industrial Electrical Maintenance Explained

By R.W. Hurst, Editor

NFPA 70b Training - Electrical Maintenance

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Industrial electrical maintenance ensures the reliability of plant and factory power systems through regular inspections, testing, and repairs. It minimizes downtime, extends equipment life, improves safety, and prevents costly failures in critical industrial operations.

What is Industrial Electrical Maintenance?

Industrial electrical maintenance (IEM) encompasses the routine upkeep, troubleshooting, and repair of electrical systems in manufacturing and industrial settings.

✅ Enhances equipment reliability through preventive maintenance

✅ Reduces unplanned downtime and costly repairs

✅ Ensures electrical safety and compliance with regulations

NFPA 70B Industrial Electrical Maintenance Training

Electrical Testing and Troubleshooting Training

Request a Free Training Quotation

Industrial electrical maintenance plays a crucial role in ensuring the safety, efficiency, and reliability of industrial facilities. By understanding the key components of a testing and repair program, including preventive maintenance, troubleshooting, equipment maintenance, and the role of automation equipment, companies can develop a robust plan that supports the overall performance and longevity of their systems. Furthermore, investing in the skills and knowledge of technicians, as well as adapting to technological advancements, are crucial for achieving long-term success in industrial electrical maintenance (IEM). Discover how advanced electrical test equipment enables teams to identify issues early and enhance safety across industrial systems.

At the core of an industrial electrical testing and maintenance program are various key components that contribute to a facility's overall success and efficiency. These include preventive maintenance, troubleshooting, and equipment repair. Preventive maintenance involves regular inspections and servicing of systems to identify and address potential issues before they escalate into significant problems. Troubleshooting involves identifying and fixing power-related issues that may arise during regular operations. Ultimately, equipment repair focuses on maintaining the integrity of components and machinery to ensure optimal performance and minimize downtime. For accurate voltage and current measurements, technicians often rely on tools like analog multimeters during regular testing routines.

Sign Up for Electricity Forum’s Test Equipment Newsletter

Stay informed with our FREE Test Equipment Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Industrial facilities rely on various types of equipment, including transformers, motors, generators, and power circuit breakers. Each of these components plays a vital role in the facility's operations. For example, transformers help regulate voltage levels to ensure a stable power supply, while motors and generators convert energy into mechanical motion and vice versa. In addition, power circuit breakers protect circuits from overloads and short circuits. Therefore, regular inspection and service of these components are essential for the smooth operation of an industrial facility.

Another critical aspect is the use of automation equipment, such as variable frequency drives (VFDs) and programmable logic controllers (PLCs). Variable Frequency Drives (VFDs) control the speed of electric motors to optimize energy consumption and reduce wear on mechanical components. At the same time, PLCs serve as the "brain" of automated systems, controlling and monitoring various processes. Therefore, properly maintaining these devices is crucial to ensuring the efficient functioning of automated processes in an industrial setting. See our guide on electrical testing to understand the methods used to verify the condition of high-voltage equipment.

Predictive Maintenance Tools and Techniques

Predictive maintenance is a proactive strategy that uses data and condition-based analysis to prevent failures. Top-performing facilities now include:

Key Predictive Tools:

-

Thermal Imaging (Infrared Thermography): Detects overheating components in panels, breakers, and motors before failure.

-

Vibration Analysis: Identifies wear or imbalance in rotating equipment, such as motors and generators.

-

Ultrasonic Testing: Used to detect arcing, corona discharge, and loose connections in high-voltage systems.

-

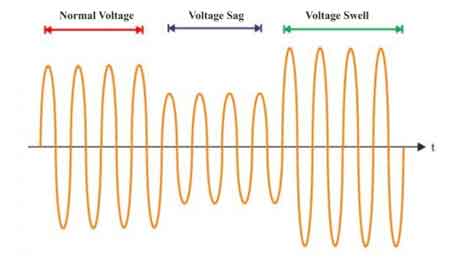

Current and Voltage Harmonic Analysis: Reveals abnormalities in power quality affecting VFDs, PLCs, and other sensitive electronics.

-

IIoT-Enabled Sensors and Remote Monitoring: Provides real-time insights into temperature, vibration, and power consumption trends across multiple assets.

Predictive maintenance reduces unplanned downtime, extends equipment life, and improves return on investment (ROI) over time compared to reactive or calendar-based methods. Troubleshooting faults is a critical skill—explore our electrical troubleshooting page for techniques and tools used in industrial settings.

The frequency of equipment inspection and service in industrial settings depends on several factors, including the type of equipment, operating conditions, and the manufacturer's recommendations. Generally, more frequent inspections are required for high-voltage or high-power equipment, while lower-voltage devices may need less frequent checks. Regular industrial electrical maintenance schedules can help detect potential problems early on and prevent costly breakdowns and downtime.

Common problems in industrial facilities include loose connections, overheating, and wear and tear. By addressing these issues through preventive testing and servicing, facilities can improve efficiency and safety. Regular inspection can also help prevent fires, equipment damage, and accidents caused by power system failures.

An IEM technician should understand principles, industrial equipment, and safety regulations. Additionally, they should be skilled in troubleshooting issues and able to work effectively with various tools and equipment. Many technicians also undergo specialized training programs to enhance their knowledge and skills in specific areas, such as PLC programming or VFD service.

Testing and troubleshooting play a crucial role in IEM. They help identify issues, assess the condition of equipment, and determine the necessary corrective actions. This process involves using specialized tools and instruments to measure parameters such as voltage, current, and resistance and analyzing the results to detect potential issues or confirm that the equipment is functioning correctly.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Lockout/Tagout (LOTO) Best Practices

LOTO is a legally mandated safety protocol (e.g., OSHA 29 CFR 1910.147) to protect workers from hazardous energy during service. Your article should include:

Best Practices for Lockout/Tagout:

-

Perform a hazard assessment before work begins to identify all energy sources.

-

Use authorized lockout/tagout devices that physically prevent the activation of energy.

-

Communicate clearly: All affected employees must be informed of LOTO procedures.

-

Follow a written energy control procedure (ECP) tailored to each piece of equipment.

-

Verify zero energy state using voltage testers before beginning any service.

-

Each worker applies their personal lock; group lock boxes can be used for teams.

-

Train employees annually on LOTO steps, responsibilities, and hazard awareness.

-

Conduct regular audits of your LOTO program to ensure compliance.

Industrial electrical maintenance planning is a crucial aspect of optimizing the performance and lifespan of equipment in industrial environments. It involves developing and implementing a structured service plan outlining equipment upkeep tasks, frequencies, and responsibilities. By adhering to a well-defined service plan, facilities can minimize unexpected equipment failures, reduce downtime, and extend the life of their components. For accurate voltage and current measurements, technicians often rely on tools like analog multimeters during regular testing routines.

To maintain a smooth-running operation, it is crucial to invest in regular training programs for technicians. This allows them to stay up-to-date with technological advancements and safety standards. Moreover, continuous learning can help them enhance their skills and better serve the needs of the industrial facility.

It's essential to remember that IEM is an ongoing process that requires constant attention and effort. Additionally, new equipment and practices must be adopted as technology advances to remain competitive. Therefore, it's vital for companies to periodically review and update their testing and service strategies and plans to accommodate advancements in technology and industry best practices.

North American Industrial Electrical Maintenance Standards

In North America, standards are developed and enforced to ensure the safe and efficient operation of systems and equipment. These standards provide guidelines for inspection, testing, and procedures, outlining best practices and safety requirements for various industrial components. By adhering to these standards, facilities can minimize hazards, reduce downtime, and enhance the overall performance of their power systems. Assessing the condition of rotating machines requires specialized procedures, such as electric motor testing, to detect imbalances and insulation failures.

Two key organizations involved in developing standards in North America are the National Fire Protection Association (NFPA) and the Institute of Electrical and Electronics Engineers (IEEE). The NFPA publishes NFPA 70E, a standard for safety in the workplace, and also publishes NFPA 70B, Recommended Practice for Equipment Maintenance. IEEE also provides numerous standards related to equipment service.

NFPA 70E - Standard for Safety in the Workplace

The NFPA 70E is a widely recognized standard that addresses safety requirements for employees working on or around equipment. This standard covers safe work practices, personal protective equipment (PPE), hazard assessment, and the development of a safety program. Additionally, it provides guidelines for minimizing risks associated with hazards such as arc flash and electric shock. Adherence to the NFPA 70E is crucial for ensuring the safety of electricians and other personnel working with industrial systems.

NFPA 70B - Recommended Practice for Industrial Electrial Maintenance

NFPA 70B is a critical standard that complements NFPA 70E by providing comprehensive guidelines for maintaining equipment in industrial, commercial, and institutional settings. This standard aims to minimize the risk of hazards, equipment failures, and unexpected downtime by outlining best practices for the proper industrial electrical maintenance of systems and components. Our NFPA 70B 2023 page outlines the updated standards for preventive maintenance of industrial power systems.

The NFPA 70B covers various aspects of equipment maintenance, including:

-

Maintenance Organization and Planning: This section emphasizes the importance of having a structured maintenance program and outlines guidelines for developing and implementing a service plan that addresses a facility's specific needs and requirements.

-

Inspection and Testing: NFPA 70B provides guidelines for inspecting and testing various types of equipment, including transformers, circuit breakers, motors, and generators. It outlines recommended test methods, frequencies, and safety precautions during these activities.

-

Preventive and Predictive Maintenance: The standard emphasizes the importance of preventive and predictive inspection and testing in extending equipment life and minimizing the likelihood of failures. It offers recommendations for implementing these service strategies effectively.

-

Equipment-Specific Maintenance: NFPA 70B provides detailed guidelines for maintaining various types of equipment, including switchgear, batteries, grounding systems, and cables. It addresses the specific service requirements, procedures, and safety precautions associated with each type of equipment.

-

Maintenance Documentation and Recordkeeping: The standard emphasizes the importance of maintaining accurate records of equipment service activities, test results, and other relevant information. These records can help identify trends, assess equipment performance, and support decision-making on service activities and equipment replacement.

-

Training and Personnel Safety: NFPA 70B emphasizes the importance of providing proper training to maintenance personnel in safety procedures, equipment operation, and service techniques. It also emphasizes the importance of adhering to safety requirements, including lockout/tagout procedures and the use of personal protective equipment (PPE).

By adhering to the guidelines outlined in the NFPA 70B, organizations can establish a robust inspection and repair program that minimizes the risk of hazards and promotes equipment reliability and efficiency. Additionally, incorporating these best practices into a facility's service strategy can reduce downtime, prolong equipment life, and enhance overall operational performance.

Related Pages