Power Factor Correction Capacitor

By R.W. Hurst, Editor

Power Quality Analysis Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

A power factor correction capacitor improves energy efficiency by reducing reactive power in AC systems. It lowers utility costs, boosts voltage levels, and reduces electrical losses, making it essential for commercial and industrial power quality and load management.

What is a Power Factor Correction Capacitor?

It is used to improve the power factor in electrical systems by offsetting inductive loads. It is commonly applied in industrial facilities to optimize energy use and reduce utility charges.

✅ Reduces reactive power to improve energy efficiency

✅ Stabilizes voltage and supports electrical system reliability

✅ Cuts demand charges and lowers electrical energy costs

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Power Factor Correction Capacitors (PFCC) are an essential component in electrical systems, designed to enhance efficiency by addressing the issue of reactive power (RP). Electrical systems often experience inefficiencies due to inductive loads, which cause excess reactive power (Q). This is where PFCCs come into play, as they reduce the amount of reactive power (RP) and improve the power factor (PF). Understanding how these capacitors work, their benefits, and best practices for their use is crucial for electrical workers aiming to enhance system performance and reduce energy costs.

PFCCs help electrical systems run more efficiently by reducing reactive energy and optimizing current flow. By compensating for phase shifts between voltage and current, they enhance energy efficiency and reduce utility charges. Businesses often use capacitors to meet energy standards and avoid penalties associated with low efficiency.

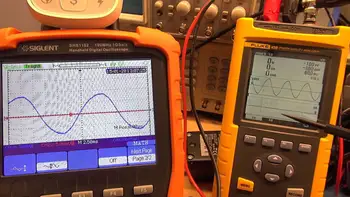

How Correction Capacitors Work

Power factor correction capacitors introduce leading current to offset the lagging current caused by inductive loads such as motors or transformers. This balance reduces strain on electrical infrastructure, improves voltage stability, and helps businesses manage peak demand costs more effectively.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

For a deeper understanding of how efficiency impacts electrical systems, visit our Power Factor Correction guide.

Capacitor Sizing Basics: How Much kVAR Do You Need?

Choosing the right capacitor size is essential for successful correction. A simple formula to estimate the required kVAR rating is:

kVAR needed = kW × (tan φ1 – tan φ2)

Where:

-

φ1 is the current phase angle

-

φ2 is the desired phase angle

Example:

A facility operating at 100 kW with an initial phase angle of 36.87° (PF 0.8) aims to increase its PF to 0.95 (phase angle 18.19°).

Using the formula:

-

tan(36.87°) ≈ 0.75

-

tan(18.19°) ≈ 0.33

kVAR = 100 × (0.75 – 0.33) = 42 kVAR

Thus, a 42 kVAR capacitor bank would be appropriate.

Need help with calculations? Try our Power Factor Calculator.

Types of Correction Capacitors

Not all capacitors are the same. Different types serve different electrical loads:

-

Low-Voltage Capacitors: Typically rated up to 1,000V, suitable for commercial buildings and smaller industries.

-

Medium-Voltage Capacitors: Rated above 1,000V, ideal for large industrial plants or utility applications.

They also come in control methods:

-

Fixed Capacitors: Always connected to the system, best for constant loads.

-

Automatic Capacitors: Switched on or off as needed through controllers, ideal for fluctuating loads.

For automated solutions, see our Automatic Power Factor Controller article.

Real-World Example: Savings from PFCC Installation

An industrial plant consuming 800,000 kWh annually noticed high demand charges due to inefficient load management. After installing a 300 kVAR automatic correction system, their monthly bills decreased by 12%, resulting in approximately $14,400 in annual savings.

Improving system efficiency not only reduced costs but also enhanced voltage stability, which protected sensitive machinery from fluctuations.

For a deeper dive into calculations, see How to Calculate Power Factor.

Installation and Maintenance Best Practices

Proper setup and regular care are critical to maximizing the lifespan and effectiveness of PFCCs:

-

Correct Placement: Install as close as possible to large inductive loads.

-

Overcurrent Protection: Use appropriate fuses or circuit breakers.

-

Periodic Inspection: Check for signs of overheating, bulging, or insulation breakdown.

-

Environment Control: Store power factor correction capacitors in cool, dry areas to extend their operating life.

If you're planning upgrades, consider reading about Capacitor Sizing and Installation Techniques.

Why PFCCs Matter

Correction capacitors are a cost-effective way to enhance electrical system performance, avoid demand penalties, and ensure stable operations. Whether using fixed banks or dynamic controllers, properly installed capacitors are crucial to modern load management strategies.

Frequently Asked Questions

What are the Benefits of Using a Power Factor Correction Capacitor?

There are numerous advantages to using PFCCs. First, they help reduce the amount of RP, resulting in a decrease in the electricity consumed by the system. This reduction results in lower electricity bills and improved energy efficiency. Additionally, by improving the PF, capacitors reduce the stress on the electrical infrastructure, minimizing energy loss and enhancing the overall PQ of the system. Furthermore, these capacitors contribute to a more reliable electrical system by reducing the load on transformers and other components, thereby prolonging their operational life.

How Do You Determine the Correct Size and Type of Power Factor Correction Capacitor?

Choosing the right PFCC depends on several factors, including the size of the inductive load, the system's electrical requirements, and the desired level of PF correction. Electrical engineers often perform calculations based on the system’s current consumption and AP to determine the appropriate size of the capacitance device. In many cases, automatic switched capacitors are utilized in systems with varying loads, enabling the dynamic adjustment of capacitance as needed. It’s essential to ensure that the capacitors are properly sized and designed to meet the specific needs of the electrical system.

What Common Issues or Problems?

Common issues include overvoltage, harmonic distortion, and improper sizing of capacitance devices. Overvoltage can occur if the device is too large for the system, potentially damaging both the cap and other system components. Harmonic distortion, caused by non-linear loads, can affect the performance of the cap and reduce the system’s overall PQ. To prevent these problems, it is essential to conduct regular maintenance and testing, ensuring that the caps are operating within the system’s parameters and that automatic switched caps are functioning correctly.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

What are Some Best Practices?

Proper maintenance is critical for ensuring the long-term performance of a PFCC. Regular inspections are necessary to ensure that the caps require minimal cleaning and replacement of components. In addition, systems should be tested periodically to measure the amount of RP and ensure that the correction PFC is effectively improving the PF. Installing protection systems, such as surge protectors, can also safeguard caps from electrical faults. Lastly, in systems where loads vary significantly, using automatic switched caps can optimize the cap's performance by adjusting to changing energy requirements, ensuring maximum efficiency and reliability.

A power factor correction capacitor is an essential tool for electrical systems seeking to reduce energy loss, enhance efficiency, and maintain optimal PQ. By reducing the amount of RP, these caps help increase the PF, resulting in lower energy costs and improved system performance. Understanding how to select, install, and maintain correct PFC caps is crucial for optimizing electrical systems and ensuring long-term reliability. Regular maintenance and dynamic adjustments, utilizing automatic switched caps, further enhance the system's efficiency and sustainability.

Related Articles