Distribution Automation Reliability

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

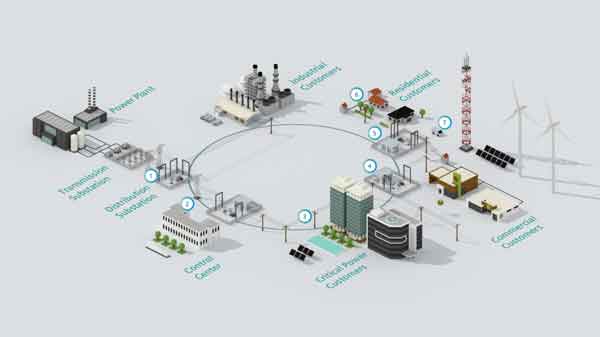

Distribution automation enhances grid reliability, efficiency, and fault detection using smart sensors, communication networks, and control systems. It supports smart grid operations, reduces downtime, and ensures consistent, safe power delivery.

What is Distribution Automation?

Distribution automation is the application of sensors, communication networks, and control technologies to monitor and optimize power distribution systems. It improves SCADA integration efficiency, reduces outages, and enables utilities to support smart grid functionality.

✅ Improves grid reliability and fault detection

✅ Enhances efficiency through real-time monitoring

✅ Supports smart grid operations and automation

Distribution automation is a vital component of smart grid modernization, enabling utilities to create more reliable, efficient, and adaptable power networks.

The Role of Distribution Automation in Power Systems

Distribution automation is one of the most important technologies driving the modernization of transmission and distribution (T&D) grids. By integrating sensors, communication networks, control devices, and software platforms, utilities can optimize performance, manage the integration of renewable energy sources, and enhance power quality.

While DA offers tremendous benefits, it also requires significant investment in infrastructure and skilled personnel. Still, most utilities recognize that the advantages outweigh the challenges, making DA a cornerstone of smart grid development and overall grid modernization. By combining DA with coordinated automation schemes, utilities can optimize system performance across substations and feeders, thereby enhancing resilience.

How Distribution Automation Works

Distribution automation systems rely on a combination of field devices and communication links. Sensors measure parameters such as voltage, current, and equipment status, while communication networks deliver this data to control centers. Software algorithms analyze the data and trigger appropriate actions. These analytics not only guide operational decisions but also support predictive maintenance, allowing utilities to anticipate failures before they occur.

Test Your Knowledge About Overhead T&D!

Think you know Overhead T&D? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

For example, if a feeder fault is detected, a DA system can remotely operate switches to isolate the problem and reroute power, restoring service to unaffected customers in seconds. This ability to detect and respond in real time minimizes downtime and enhances resilience. The success of DA depends on advanced data analytics, which transform real-time sensor data into actionable insights for operators.

Technical Applications of Distribution Automation

| DA Function / Application | Technical Description | Utility Benefit | Customer Impact |

|---|---|---|---|

| Fault Detection, Isolation, and Service Restoration (FDIR/FLISR) | Automated detection of faults, isolation of faulted sections, and restoration of power to unaffected areas. | Reduces SAIDI/SAIFI indices, lowers outage duration. | Faster restoration and fewer service interruptions. |

| Volt/VAR Optimization (VVO) | Uses sensors, regulators, and capacitor banks to maintain voltage within optimal limits. | Improves power quality, reduces system losses, supports DER. | More stable voltage, lower energy costs. |

| Conservation Voltage Reduction (CVR) | Adjusts feeder voltage closer to lower operational limits without violating standards. | Reduces peak demand and overall energy consumption. | Lower electricity bills without reduced performance. |

| Remote Switching & Control | Intelligent electronic devices (IEDs) allow remote operation of switches and reclosers. | Improves operational flexibility, reduces truck rolls. | Faster fault response, reduced outage duration. |

| Distributed Energy Resource Management (DERMS) | Integrates solar, wind, and battery storage into grid operations using real-time monitoring. | Balances supply-demand, enhances renewable integration. | Reliable service even with high levels of renewable energy penetration. |

| Automated Feeder Reconfiguration | Real-time reconfiguration of feeder topology in response to load changes or outages. | Optimizes load flow, prevents overloads, and improves reliability. | Stable supply even during high demand or equipment failures. |

| Predictive Maintenance | Uses sensor data and analytics to anticipate equipment failures before they occur. | Extends asset life, reduces maintenance costs. | Fewer unplanned outages, improved service reliability. |

Benefits for Utilities and Customers

Distribution automation is more than just a technical upgrade; it transforms the way utilities operate and how customers experience electric service. By creating a smarter, more responsive grid, distribution automation reduces disruptions, improves efficiency, and supports a sustainable energy future. For customers, this means fewer outages and more reliable service. Utilities must also be mindful of security, as highlighted in the DHS/FBI alert on vulnerabilities affecting critical infrastructure. Utilities must also adopt a robust grid cybersecurity strategy to safeguard DA systems from digital threats. For utilities, it means streamlined operations and the ability to meet growing energy demands without proportional increases in cost. These advantages span across operational, economic, and customer service dimensions, making DA a cornerstone of modern grid management.

-

Reliability: DA systems detect and respond to faults instantly, reducing the duration and frequency of outages.

-

Efficiency: By optimizing power flows and reducing energy losses, DA improves overall system performance.

-

Renewable integration: DA helps manage the variability of solar, wind, and other distributed energy resources, improving flexibility and stability.

-

Cost savings: A reduced need for manual inspections and faster restoration, lower utility operating expenses.

Key Components of Distribution Automation

The effectiveness of distribution automation relies on the seamless integration of multiple technologies. Each component plays a specific role, but together they form a system capable of monitoring, analyzing, and responding in real-time. Utilities rely on this integration to maintain reliability and efficiency while adapting to new demands, such as integrating renewable energy sources and increasing electrification. To function effectively, these automated distribution networks rely on interoperability, guided by standards such as IEC 61850 and IEEE 1547. Understanding these components helps explain how DA functions as the nervous system of a modern grid, continuously sensing, communicating, and adjusting to maintain stability.

-

Sensors – Monitor voltage, current, temperature, and equipment conditions.

-

Communication networks – Wired or wireless platforms that connect field devices with control centers.

-

Control devices – Switches, capacitors, and regulators that can be operated remotely to manage the grid.

-

Software platforms – Analytical tools and algorithms that process data and optimize grid operations.

Together, these elements form the backbone of automated decision-making in modern distribution systems, allowing utilities to run a more intelligent and adaptive network. Protecting distribution automation systems requires a comprehensive grid cybersecurity strategy that safeguards communication and control networks.

Reliability and Fault Detection

Fault detection and location (FDL) is a critical feature of DA. By quickly identifying and isolating faults, utilities can minimize outages and restore service faster. This capability not only enhances reliability but also boosts customer satisfaction.

Supporting Renewable Energy Integration

As more renewable energy sources connect to the grid, DA plays an increasingly important role. Variable and intermittent resources such as solar and wind require real-time monitoring and balancing. DA systems, often combined with advanced metering infrastructure (AMI), help maintain stability while supporting a sustainable energy transition.

Challenges of Implementing DA

Despite the benefits, DA adoption is not without hurdles. Utilities must invest heavily in infrastructure, train skilled personnel, and coordinate across multiple departments to ensure seamless operations. To ensure reliable operations, utilities combine DA with advanced sensor technology that enables faster fault detection and real-time system monitoring, adhering to standards such as IEC 61850 and IEEE 1547. These standards add further complexity but ensure interoperability and reliability.

One of the biggest barriers is capital investment. Deploying sensors, communication networks, and intelligent devices across a distribution system requires substantial upfront funding. Smaller utilities may struggle to justify costs without regulatory incentives or clear cost-recovery mechanisms.

Another challenge lies in interoperability. Many DA systems involve equipment from multiple vendors, and ensuring seamless communication between devices requires adherence to standards such as IEC 61850 and IEEE 1547. Without interoperability, utilities risk fragmented systems that are less reliable and harder to scale.

Sign Up for Electricity Forum’s Overhead T&D Newsletter

Stay informed with our FREE Overhead T&D Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Cybersecurity is also a growing concern. Because DA depends on digital communication networks and remote control systems, it introduces vulnerabilities that could be exploited by malicious actors. Protecting grid data and control systems requires continuous investment in cybersecurity strategies, including encryption, intrusion detection, and workforce training.

Finally, DA requires a skilled workforce capable of designing, installing, and maintaining advanced systems. Training engineers and operators to manage new technologies adds another layer of complexity to the implementation process.

Together, these challenges highlight that while DA is essential for modernizing the grid, it demands thoughtful planning, strong governance, and ongoing investment to achieve success.

Standards Guiding Distribution Automation

The success of distribution automation depends not only on advanced technologies but also on the consistent use of industry standards. Standards act as the blueprint that ensures DA systems are safe, reliable, and interoperable across different devices, vendors, and utility networks. Without them, utilities would face compatibility issues, fragmented systems, and reduced effectiveness.

-

IEC 61850 – Defines communication protocols for relays, switches, and control systems.

-

IEEE 1547 – Establishes technical requirements for integrating distributed energy resources.

-

NEMA SG-3 and SG-4 – Cover requirements for substation and distribution transformers.

-

CIGRE WG D2.27 – Provides guidelines for fault detection and location systems.

Compliance with these standards not only promotes interoperability but also ensures that DA investments deliver measurable improvements in reliability, efficiency, and sustainability.

Distribution automation is not just a technical upgrade; it is a strategic investment in the future of reliable, efficient, and sustainable power systems. By combining sensors, communications, and intelligent controls, utilities can modernize their grids, integrate renewable energy sources, and deliver higher-quality service to their customers. Despite the upfront challenges, distribution automation is indispensable for 21st-century utilities seeking intelligent grid management and resilient automated distribution networks. As DA evolves, it plays a key role in overall grid modernization, integrating renewable resources and enhancing customer reliability.

Frequently Asked Questions

How does distribution automation differ from traditional grid management?

Traditional grid management relies heavily on manual monitoring and switching, whereas distribution automation utilizes real-time sensors, remote control devices, and automated decision-making to detect and resolve issues more efficiently with reduced human intervention.

What role does cybersecurity play in distribution automation?

Because DA relies on digital communication networks, it introduces new cybersecurity risks. Utilities must implement robust security protocols to protect control systems and data streams from potential cyber threats that could disrupt grid operations.

Can distribution automation reduce greenhouse gas emissions?

Yes. By improving efficiency and integrating renewable energy sources more effectively, DA helps utilities reduce dependence on fossil-fuel generation and lower overall carbon emissions across the power system.

Is distribution automation only for large utilities?

No. While large utilities are often first movers, municipal and cooperative utilities also benefit from DA. Scaled solutions enable smaller utilities to enhance reliability and customer satisfaction without implementing the full infrastructure all at once.

What future technologies will enhance distribution automation?

Advancements in artificial intelligence, edge computing, and predictive analytics will expand DA capabilities. These tools will enable utilities to anticipate faults before they occur and optimize grid performance with even greater precision.

Related Articles