Latest Motors and Drives Articles

Variable Frequency Drive HVAC Explained

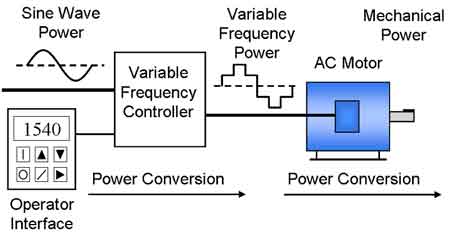

A Variable Frequency Drive (VFD) in HVAC systems adjusts motor speed and torque to control fans, pumps, and compressors, thereby boosting energy efficiency, lowering costs, reducing wear, and enhancing comfort in heating, ventilation, and air conditioning.

What is Variable Frequency Drive HVAC?

A Variable Frequency Drive (VFD) in HVAC is an electronic device that regulates motor speed and torque to control fans, pumps, and compressors, thereby optimizing system efficiency.

✅ Improves energy efficiency and lowers operating costs

✅ Enhances motor performance and building comfort

✅ Extends equipment lifespan with reduced wear

Electric Motor Testing Training

Request a Free Training Quotation

Variable Frequency Drives (VFDs) in HVAC systems allow operators to adjust the speed of motors rather than running at full speed continuously. By enabling users to control the speed of fans, pumps, and compressors, variable frequency drives VFDs and variable speed drives deliver significant energy savings and help reduce energy consumption across large facilities. In addition to efficiency, VFDs provide soft starts that limit inrush current, protect equipment, and extend motor life. This smoother operation also reduces maintenance demands while improving comfort through better airflow and water flow regulation. Overall, VFDs in HVAC systems optimize performance, reliability, and sustainability.

All buildings face the same challenge: how to heat or cool the air inside to create a more comfortable environment for their occupants. In small buildings such as a house, this task is easily handled with air conditioners and heaters. Larger buildings, such as offices, hotels, or factories, pose a more challenging problem due to their size and complexity. The most typical heating and cooling solution involves circulating air around the building while adjusting the air temperature by passing it over heated or cooled water as needed. Such a system consists of a water stage and an air stage. For deeper insight into how they function, see how does a VFD work and its role in reducing wear on motors used in HVAC systems.

Water Stage

The water stage is the first step of temperature control. Air is not an efficient medium for direct heating or cooling. The most efficient and inexpensive medium for heating or cooling is water. This water can then be used to change the temperature of the air passing through it. Heating water is very simple. Municipally-supplied water is pumped into a boiler where it is exposed to heat from oil, gas, coal, or electricity. The hot water is then pumped out into coils used for heating the building's air. Cooling water is a little more complex and revolves around a device called a chiller. A chiller consists of a compressor, a condenser, and an evaporator. Two separate water circuits exist in the chiller: one circuit removes heat from the building air, and another dissipates that heat via a cooling tower. Facilities can further optimize performance by combining VFD HVAC technology with efficiency opportunities through motor maintenance, ensuring reliable long-term operation.

Air Stage

The air stage is the medium for heat exchange in the building spaces. Air is constantly circulated through a building to either bring in or carry away heat as required. If the air needs to be cooled, it is directed over coils of cool water. If the air needs to be heated, it flows over coils of hot water. Outside air is also vented in at times to save chiller energy when the outside air temperature is cool enough to help the system.

HVAC System Architecture

Every building, when designed, presents a different type of heating and cooling challenge. Correspondingly, a wide range of HVAC solutions has been developed over the years, particularly for large buildings. Professionals seeking to master this technology can expand their skills through variable frequency drive training, tailored to HVAC and industrial applications.

Single Zone System

The simplest and common of all HVAC designs is the single duct/single zone system. This system is designed to supply air at a single temperature to a single large area (or zone) of a building. Some buildings are designed with the entire structure as a single zone. Although this system is simple and inexpensive to construct, the lack of control makes it difficult to keep all of the occupants comfortable, especially if parts of the building are affected differently by wind or sunlight. This type of system also wastes energy when heating or cooling areas that do not require it. Engineers designing HVAC systems benefit from understanding electric motor efficiency, since VFDs maximize savings only when paired with efficient motors.

The most flexible part of a single-zone system is the selectable recirculation of building air. Selectable air recirculation is a common feature in most HVAC architectures and is incorporated into all the systems discussed here. In this design, outside air is only used if its temperature will move the building temperature in the desired direction, warmer or colder. If the outside air is not at a useful temperature, the outside air dampers may be closed and the intermix damper opened to allow the building air to recirculate. However, the outside air dampers do not close completely. Some outside air must be brought in for health reasons. It is a general requirement that 20 cubic feet per minute of air be brought in for each occupant at all times. When applied to HVAC, a variable frequency drive adjusts motor operation to meet real-time load demands, lowering costs and boosting efficiency.

Terminal Re-heat System

A slightly more sophisticated system is called terminal reheat. These systems distribute uniformly cool or hot air to multiple zones within a building. Each zone is equipped with a thermostat and a heating coil. When a zone’s thermostat calls for warmer air, a heating coil is activated to provide the required heat.

Cooling Systems

Providing cooling is the most complex part of HVAC systems. The two primary components used to achieve this are chillers and cooling towers. By integrating VFDs with electric motor control, HVAC systems achieve precise speed regulation for fans and pumps, improving comfort and reducing waste.

Chillers

A chiller is the primary means of heat exchange between the interior and exterior of a building. The chiller serves two basic functions: to cool the air in a building and to provide dehumidification.

Water enters the evaporator and the condenser through external piping. Tubing inside the piping is surrounded by a chiller medium, which is a compressible gas such as freon. As the water circulates within the tubing, heat is transferred between the water and the chiller medium. The chiller medium is subjected to two stages of pressurization. First, the medium is fed into the condenser at high pressure by the compressor. When the medium is compressed, its temperature increases. The chiller medium then leaves the condenser through an expansion device that suddenly lowers the medium’s pressure before it enters the evaporator. When the medium is thus expanded, its temperature decreases. The change in pressurization between these two stages is the key to the cooling provided by the chiller.

From: Electric Motors and VFDs Handbook, Vol 4, The Electricity Forum

Related Articles

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

What is Starting Current? Motor Efficiency Explained

Starting current is the surge of electricity when a motor first begins turning. This inrush current, far higher than normal, influences torque, efficiency, power factor, protective devices, and overall electrical system stability during startup.

What is Starting Current?

Starting current, sometimes referred to as "inrush current," is the surge of electricity drawn by a motor during startup, usually several times higher than normal operating current.

✅ Causes mechanical stress and voltage dips

✅ Impacts circuit breakers, fuses, and protective devices

✅ Managed by soft starters or VFDs to improve reliability

Starting current is often used interchangeably with inrush current or surge current, both of which describe the brief but intense demand placed on a system when a motor is first energized. In motor applications, this phenomenon is closely related to locked rotor current, the maximum current drawn when the rotor is stationary and torque is required to overcome inertia. At this point, the motor operates on the steepest part of the torque-speed curve, where starting torque must be high enough to accelerate the load while the electrical system sustains the temporary spike in current. Engineers and electricians rely on full-load current ratings as a baseline to estimate how many times higher the inrush current will be, since inrush current can range from four to eight times the rated load, depending on the motor size and design.

The effects of inrush current extend beyond the motor itself. High inrush can cause a voltage sag on the supply line, which may trip sensitive devices or reduce performance of other equipment sharing the same circuit. To prevent false trips and ensure reliability, protective systems are designed with a motor protection relay, which can differentiate between temporary inrush and sustained overload. By coordinating motor protection with system design, electricians can reduce the risks associated with inrush current, protect connected equipment, and ensure stable operation across industrial and commercial power systems.

Electric Motor Testing Training

Request a Free Training Quotation

Every industrial electrician must thoroughly understand this concept to ensure the safety and efficiency of electrical systems. This surge of electricity, far exceeding normal operating current, occurs in the instant an electrical device is switched on. From preventing unexpected short-circuit trips and equipment damage to implementing effective mitigation strategies, such as soft starters and star-delta configurations, this article provides a comprehensive overview of inrush current, its causes, effects, and practical solutions. Read on to gain the knowledge necessary to confidently tackle current challenges in your industrial electrical work.

Why Starting Current Is So High

Starting current, commonly referred to as high inrush current, is the initial surge of electrical energy required to power up a device such as an induction motor. This brief but intense burst occurs the moment the device is switched on and is often significantly higher than the operational current drawn during regular operation. This phenomenon is a critical consideration for engineers and electricians when designing systems that must accommodate the demands of motor starting, especially in industrial settings where electric motors play a pivotal role.

One of the key reasons the inrush current is higher than the running current is the low initial impedance of devices like motor windings. At the moment of activation, motors face the challenge of overcoming inertia while simultaneously creating the magnetic fields necessary for operation. This lack of back electromotive force (EMF), which usually opposes and reduces the flow of energy during regular operation, means the motor draws a large amount of energy from the system. In devices such as power converters, the charging of internal capacitors can also contribute to this surge, amplifying the demand placed on the system. High inrush current can reduce efficiency if not properly managed, which is directly related to electric motor efficiency strategies aimed at minimizing losses and enhancing performance.

Typical Values and Calculation

Starting current is commonly 5 to 8 times the full-load current (FLC) for small induction motors (1–5 HP). For larger machines (20–100 HP), the multiplier may be closer to 4 to 6 times FLC, as design and efficiency reduce the relative inrush.

A general formula often used is:

Starting Current (Is) = Locked Rotor Current (ILR) ≈ Full-Load Current (IFL) × k

Where k is typically between 4 and 8, depending on motor size and type.

Example:

A 10 kW induction motor with a full-load current of 60 A may have an inrush current of:

Is = 60 A × 6 = 360 A.

Using a soft starter, this can often be reduced to ~150 A, cutting voltage sag from 8% to 2%.

Motor Types and How They Differ

Different motor types exhibit distinct behaviour at startup, and understanding these differences enables electricians and engineers to select the appropriate protective devices and mitigation strategies. The magnitude of inrush current, duration of the surge, and overall impact on the system depend heavily on motor design.

-

Induction Motors: Typically 5–8× full-load current at startup, due to lack of EMF and inertia load.

-

Synchronous Motors: May have even higher surges without starting assistance, requiring external starters.

-

DC Motors: The inrush current depends on the armature's resistance and is often controlled with series resistors.

-

Universal Motors: High inrush but short duration, common in appliances.

Inrush current challenges also influence electric motor design, where winding configurations and rotor construction determine locked rotor current levels.

Terminology Clarified

Starting current is often confused with other electrical terms. Distinguishing between these related concepts facilitates the accurate analysis of motor performance and the design of effective systems. Each has a specific meaning in motor theory and practical applications.

-

Locked Rotor Current: Current drawn when the rotor is not moving (worst-case startup condition).

-

Locked Rotor Torque: Torque available at that same condition, critical for load acceleration.

-

Starting Torque vs Running Torque: Startup torque must overcome inertia; running torque maintains motion.

-

Surge Current / Inrush Current: Alternative terms for the same initial high current.

-

Startup Current Curve: Graph showing peak current at switch-on, decaying toward running current as EMF builds.

Preventing failures caused by repeated inrush is a crucial part of effective electric motor maintenance, which helps extend equipment life while reducing unplanned downtime.

Effects on Electrical Systems

through the electrical system, causing protective devices to trip, power quality issues, or premature equipment aging. Understanding these effects ensures better design and maintenance practices.

-

Circuit breakers and fuses may trip under the sudden load, causing unnecessary interruptions in power supply.

-

Voltage drops / sags are common when the motor draws more than the system can momentarily provide. Sensitive equipment connected to the same line may malfunction.

-

Thermal stress: Repeated surges heat up motor windings and insulation, leading to premature failure.

-

Harmonics and ripple effects: Fast switching and frequent restarts can increase distortion, affecting nearby devices.

Mitigation Strategies

Although inrush current is unavoidable, there are proven methods to reduce its negative effects. Choosing the right strategy depends on motor size, load characteristics, and cost considerations. Each option offers trade-offs between performance, protection, and expense.

-

Soft starters: Gradually increase voltage, reducing surge and mechanical shock.

-

Star-delta starters: Begin with a star connection to limit draw, then switch to delta for full load.

-

Variable frequency drives (VFDs): Provide precise control over voltage and frequency, reducing inrush current to 125–150% of rated current.

-

Motor protection relays: Monitor inrush and trip settings to prevent false faults.

Cost vs benefit:

-

VFDs are more expensive but provide the best control and energy savings. Modern solutions like VFDs are powerful tools for reducing inrush, and learning how does a VFD work explains why they are preferred in critical applications.

-

The star-delta configuration is cheaper but less effective for high-inertia loads.

-

Soft starters strike a balance between cost and performance for most industrial motors.

Because protective devices must react to large surges, knowledge of electric motor control is crucial for striking a balance between safety and operational reliability during startup.

Standards and Regulations

-

Global and national standards provide guidance on acceptable levels of inrush current and the application of protective devices. Compliance not only ensures safety but also reduces the risk of equipment damage and downtime due to improper system design.

-

NEMA (National Electrical Manufacturers Association): Defines locked rotor current codes for motors.

-

IEC standards (IEC 60034): Provide guidance on allowable inrush current ratios.

-

NEC / NFPA 70: Require protective devices to be sized for motor inrush without nuisance tripping.

-

CSA standards in Canada: Mirror IEC guidance with national adaptations.

Compliance ensures that protective devices, such as circuit breakers and fuses, handle line inrush without premature operation.

-

Practical Examples

Real-world applications demonstrate how starting current can disrupt systems and how mitigation strategies lead to measurable improvements. These examples, drawn from industrial, commercial, and residential settings, show both the risks of unmanaged inrush and the benefits of proper control.

-

Industrial Pump Station: A 10 kW induction motor with 60 A FLC produced 360 A inrush current. This resulted in an 8% voltage dip on the local bus. After installing a soft starter, the peak was reduced to 150 A, and the sag dropped to 2%.

-

HVAC Compressors: Inrush surges often trip undersized breakers; VFD retrofits allow smoother startup, lowering stress on both motors and building power systems.

-

Household Appliances: Refrigerators and air conditioners draw high surge currents briefly, but modern designs often integrate inrush limiters.

Since starting current is directly tied to locked rotor behavior, comparing synchronous motors and induction motors highlights the different ways each motor type manages initial torque and inrush.

Checklist

In essence, starting current is the initial surge of electricity that flows through an electrical device when it's first turned on. This surge, often significantly higher than normal operating current, occurs due to the low initial impedance of motor windings. While essential for getting devices running, high inrush current can cause voltage dips, trip circuit breakers, and damage equipment. Understanding this phenomenon and implementing mitigation strategies such as soft starters, star-delta starting, or VFDs are crucial for ensuring safe and efficient operation.

Checklist for managing starting current:

-

Calculate the expected inrush using the full-load current and the locked rotor ratio.

-

Compare the starting torque vs the running torque requirements of the load.

-

Verify that protective devices are sized to prevent nuisance trips during inrush.

-

Evaluate mitigation strategies (soft starter, VFD, star-delta).

-

Ensure compliance with NEMA, IEC, and NEC standards.

-

Monitor startup duration and acceleration time to avoid overheating.

Related Articles

Electric Motor Design Engineering

Electric motor design enhances efficiency, torque, and speed control by applying principles of electromagnetism. Optimized stator, rotor, and winding configurations deliver reliable performance, durability, and energy savings across industrial power applications.

What is Electric Motor Design?

Electric motor design is the engineering process of creating efficient, durable, and high-performance motors that convert electrical energy into mechanical motion.

✅ Balances electric motor efficiency, torque, and speed control

✅ Uses stator, rotor, and winding optimization

✅ Ensures reliability in industrial and consumer systems

Electric Motor Testing Training

Request a Free Training Quotation

Types of Electric Motors

Electric motors, including both AC motors and DC motors, come in a wide range of shapes and sizes. Some are standardized for general-purpose use, while others are tailored for specific applications. The main categories include:

-

AC Induction Motors – rugged, low-cost, and common in industrial applications.

-

Synchronous Motors – operate at constant speed with higher efficiency and power factor.

-

DC Motors – provide precise control but require brushes and commutators.

-

Brushless DC (BLDC) Motors – efficient, reliable, and widely used in EVs and appliances.

-

Stepper Motors – offer incremental motion for robotics and automation.

-

Linear Motors – produce direct linear motion without gears.

-

Switched Reluctance Motors – simple construction with high torque density, increasingly popular in EV design.

Each type involves trade-offs in cost, efficiency, control complexity, and application suitability.

Electric Motor Types Comparison

| Motor Type | Key Features | Advantages | Common Applications |

|---|---|---|---|

| AC Induction Motor | Rotor induced by stator field | Low cost, reliable, low maintenance | Pumps, fans, conveyors |

| Synchronous Motor | Rotor speed equals stator field speed | High efficiency, good power factor | Compressors, power correction |

| DC Motor | Uses brushes and commutators | Simple control of speed and torque | Cranes, hoists, rolling mills |

| Brushless DC (BLDC) | Permanent magnets, electronic drive | High efficiency, quiet, long life | EVs, appliances, robotics |

| Stepper Motor | Moves in discrete steps | Precise positioning, open-loop | CNC machines, 3D printers |

| Linear Motor | Produces linear motion | Direct motion, no gears required | Maglev trains, automation |

| Switched Reluctance | Reluctance torque, simple rotor | High torque density, robust design | EVs, aerospace, heavy drives |

Motor Selection Criteria

Regardless of type, motors should be selected to meet the dynamic requirements of the machine they drive without exceeding rated temperature. The first and most important step is determining load characteristics, specifically, torque and speed as a function of time. Motor selection also depends on mission goals, available power, and cost, as well as proper motor overload protection.

Torque and Acceleration

Starting and running torque are crucial in determining the size of motors. Requirements can vary from a fraction of full load to several times the rated torque. Variations occur due to load conditions or machine characteristics, such as lubrication or wear. The motor’s supplied torque must always exceed that required from start to full speed. Greater reserve torque allows faster acceleration.

When gear reducers are involved, rotating parts move at different speeds. To calculate the required acceleration torque, all component inertias must be reduced to a common reference point, typically at the drive shaft.

Electric Motor Power Rating

Electric motors provide the horsepower necessary to drive a machine. The common equation is:

hp = (torque × rpm) / 5,250

For variable loads, a horsepower vs. time curve helps determine both peak and RMS values. RMS load horsepower defines the continuous rating, while peak load horsepower indicates short-term capacity. If a peak is sustained, the motor rating must at least equal that load.

Duty Cycle

Loads vary widely across applications. Fans and blowers operate continuously, while compressors or pumps may start and stop frequently. Some machine tools cycle many times per minute. Duty cycle—the ratio of on-time to total cycle time—becomes a crucial factor when motors idle or operate at reduced load for extended periods. Effective electric motor maintenance helps manage these stresses and extend equipment life.

Frequent starting consumes far more energy than steady operation, risking overheating. At a constant speed, torque is directly proportional to horsepower; however, during acceleration or overloads, equivalent horsepower is used. Examining motor performance curves helps ensure sufficient torque for friction, acceleration, and overload conditions.

Service Factors

NEMA standards define motor service factors and allowable temperature rise. A service factor above unity indicates a motor can be overloaded without overheating. For example, Class-B insulated motors with service factors of 1.15 and 1.25 are rated for the same 90°C rise; however, the higher service factor motor must be larger to dissipate the extra heat.

Service factors account for occasional overloads, undefined service conditions, or cooler-than-normal operation, thereby extending insulation life.

Materials and Magnetic Core Design

Magnetic materials play a critical role in performance. Laminated steel reduces eddy current losses, while silicon steel and soft magnetic alloys improve efficiency. Permanent magnets enhance torque density in BLDC and synchronous machines; however, cost and supply chain issues, particularly with rare-earth magnets, must be considered. Rotor slot shapes, bar configurations, and stator lamination geometry also influence torque ripple, efficiency, and manufacturability.

Loss Analysis and Efficiency Trade-Offs

Motor efficiency depends on minimizing losses:

-

Copper Losses – resistance heating in windings.

-

Iron Losses – hysteresis and eddy currents in the core.

-

Mechanical Losses – friction and windage in bearings and fans.

-

Stray Losses – leakage flux and harmonics.

Designers balance conductor size, lamination thickness, cooling, and material choice against cost, weight, and efficiency targets. Increasing copper content lowers resistance but increases cost and weight. Thin laminations cut eddy losses but complicate manufacturing.

Thermal and Cooling System Design

Heat management is vital. Motors use insulation systems rated by class, ensuring windings and cores remain within safe limits. Cooling methods include:

-

Natural air cooling – simple and low-cost.

-

Forced air cooling – fans to move heat away.

-

Liquid cooling – for high-density applications like EVs.

Thermal runaway can damage insulation and reduce motor life, so accurate thermal modeling is essential.

Simulation, Modeling, and Design Tools

Modern motor design relies on advanced tools:

-

Finite Element Analysis (FEA) for electromagnetic fields.

-

Computational Fluid Dynamics (CFD) for cooling airflow.

-

Multiphysics Simulation to couple electrical, thermal, and structural performance.

These tools predict losses, optimize designs, and shorten development cycles.

Standards, Nameplate Data, and Compliance

International standards (NEMA, IEC) define performance, efficiency, and safety. Nameplate data typically includes horsepower, voltage, current, efficiency class, duty cycle, power factor, and frame size. Engineers use this information to verify the suitability of the system for specific loads and ensure compliance with efficiency regulations.

Application-Specific Constraints

Motor design adapts to industry needs:

-

EVs – demand high torque, high efficiency, and compact size.

-

Aerospace – requires lightweight, fault-tolerant motors.

-

Industrial equipment – emphasizes durability and reliability.

Environmental considerations include noise, vibration, and cooling requirements. Cost factors, availability of rare earth materials, and manufacturability also shape design choices. In many cases, variable frequency drives are applied to optimize energy efficiency and improve control.

Design Geometry Considerations

Air gap size directly influences efficiency and torque production. Rotor and stator geometry, winding type (distributed or concentrated), and number of poles affect torque ripple, harmonic distortion, and manufacturability. Small changes in geometry can improve performance, but may also increase costs.

Cost and Manufacturability

A practical motor must strike a balance between performance and economic feasibility. Design decisions consider:

-

Material costs and availability.

-

Ease of winding and insulation.

-

Tolerance requirements for laminations and machining.

-

Overall manufacturability at scale.

Trade-offs between cost and performance guide final design choices.

Electric motor design is a complex balance of electromagnetic theory, materials science, thermal management, standards, and application needs. By addressing torque, power, duty cycle, losses, cooling, and manufacturability, engineers design reliable and efficient motors tailored to meet the demands of modern industrial, commercial, and consumer applications. Learn more in our Electric Motors and Drives guide.

From: Electric Motors and VFDs Handbook, Vol. 3, The Electricity Forum

Learn How An Electric Motor Transforms Potential Energy Into Mechanical Energy

An electric motor transforms potential energy into mechanical energy. Via electromagnetic induction, it delivers shaft torque through rotor-stator interaction, optimizing efficiency in AC and DC drives, automation, robotics, and industrial motion control.

How Does an Electric Motor Transform Potential Energy into Mechanical Energy?

It means a motor converts stored energy into shaft work via electromagnetic forces, producing torque and motion.

? Converts stored potential to rotational kinetic energy (electromagnetic)

? Rotor-stator magnetic fields generate torque on the shaft

? Used in AC/DC drives, robotics, CNC, pumps, and fans

An electric motor transforms potential energy into mechanical energy, a process that underpins countless modern technologies and industrial applications. It is similar to how an electric motor transforms electrical energy into mechanical energy. For engineering and maintenance professionals, understanding this transformation is critical to optimizing machinery, ensuring energy efficiency, and maintaining operational reliability. Electric motors power everything from manufacturing equipment to transportation systems, making their proper selection, operation, and upkeep essential for minimizing downtime and reducing costs. By exploring the science behind this energy conversion, professionals can gain insights that enhance performance, improve sustainability, and drive innovation in their respective fields. For a clear primer on core principles and components, this explainer on how electric motors work helps frame the conversion from input power to motion.

Electric Motors and VFD Drives Training

Many teams also clarify terminology early by reviewing what VFD stands for to align maintenance, controls, and procurement discussions.

Request a Free Training Quotation

At the heart of every motor lies electromagnetism, a fundamental force of nature. When a current flows through a conductor, it generates a magnetic field. This field interacts with magnets or other conductors to create motion. The design harnesses this principle to drive rotors, enabling mechanical energy output. The interplay between magnetic fields and currents underlies energy conversion in these devices.

The transformation of potential energy into kinetic energy is a finely tuned process. A motor begins with an energy input, often supplied by batteries or power grids. This energy generates a magnetic force, which, in turn, causes components such as rotors to rotate. This rotation produces mechanical energy, which powers various devices. The efficiency of this conversion process is a key focus for engineers, as reducing energy loss can enhance performance across applications. Engineers can benchmark designs against accepted metrics by consulting guidance on electric motor efficiency to identify loss mechanisms and opportunities for improvement.

The internal structure reveals its complexity and ingenuity. Components such as the rotor, stator, coils, and commutators work together seamlessly. The rotor, typically made of metal or composite materials, rotates within the stator, which houses the coils. These coils carry the current that produces the magnetic field. In direct current motors, the commutator switches the current direction, ensuring smooth, continuous rotation. Each part is essential for functionality, reflecting a careful balance of design and materials. These hardware fundamentals underpin strategies in electric motor control that govern torque, speed, and dynamic response.

Motors are omnipresent in today’s world, powering devices in industries, transportation, and everyday life. From the precision of robotic arms on assembly lines to the quiet efficiency of EVs, these are indispensable. They also find applications in home appliances like washing machines, refrigerators, and fans, where their energy efficiency and reliability enhance daily convenience. By transforming potential energy into mechanical energy, they enable innovations that define modern living. In many of these applications, performance and energy savings are improved with a variable frequency drive that modulates motor speed to match real-time demand.

The diversity of motors highlights their adaptability. Alternating current (AC), direct current (DC), and step motors are among the most common types. AC ones are widely used in large-scale industrial applications due to their robustness and efficiency. DC ones, on the other hand, excel in scenarios requiring precise speed control, such as in EVs. Stepper motors, with their ability to control incremental movements, are critical in robotics and automated systems. This variety allows engineers to choose the right motor for specific tasks, optimizing performance and cost-effectiveness. Within AC families, the widely used induction design is summarized here in an overview of induction motors that covers operation, benefits, and common use cases.

Motors continue to evolve, driven by advancements in materials science, electronics, and energy management. Innovations such as brushless motors and superconducting materials are setting new benchmarks for efficiency and power density. Meanwhile, researchers are exploring novel applications, from powering drones to driving renewable energy technologies like wind turbines. These developments promise to expand the role of motors in shaping a sustainable future. Complementing these advances are modern frequency converters that enhance grid compatibility and precision control in high-performance systems.

An electric motor transforms potential energy into mechanical energy through a remarkable interplay of science and engineering. By leveraging electromagnetism, optimizing energy conversion, and refining components, these devices power countless applications that define modern life. As technology advances, they will undoubtedly continue to play a pivotal role in driving innovation and progress.

Related Articles

VFD Variable Frequency Drive

A VFD Variable Frequency Drive controls AC motor speed and torque by adjusting voltage and frequency. They improve motor efficiency, ensure drive performance, and reduce energy consumption in industrial, commercial, and HVAC applications.

What is a VFD Variable Frequency Drive?

A VFD Variable Frequency Drive is an electronic device that regulates AC motor speed and torque for optimized performance and energy savings.

✅ Improves motor efficiency and energy consumption

✅ Enhances AC motor control and drive performance

✅ Extends equipment lifespan with smoother operation

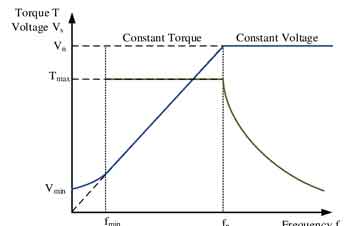

A modern AC drive, also known as an adjustable frequency drive or variable speed drive, allows operators to control the speed of motors by varying the frequency and voltage supplied to the motor windings. At the core of a frequency drive VFD are power electronics such as the insulated gate bipolar transistor (IGBT), which switch rapidly using pulse width modulation (PWM) techniques to deliver precise control. These technologies enable variable frequency drives (VFDs) to optimize performance, reduce mechanical stress, and save energy across industrial and commercial systems. By fine-tuning motor operation, an AC drive extends equipment life and enhances efficiency, making it one of the most effective tools for modern motor management.

Electric Motor Testing Training

Request a Free Training Quotation

Why does a VFD-operated motor produce more torque than across-the-line starting?

When you start an induction motor directly on line power, it pulls a surge of current because the motor is “standing still” while the supply is trying to drive it at full speed. This sudden demand creates a locked rotor current, many times higher than the normal operating current.

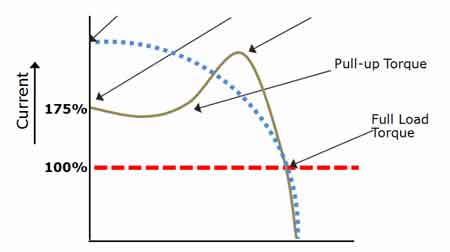

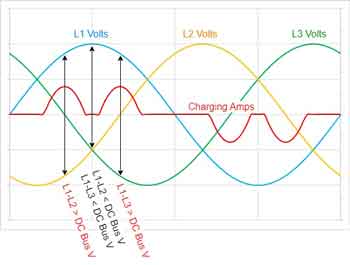

Starting an AC motor across the line causes a high locked rotor current to flow due to the difference between the stator rotating field and the rotor rotating field. At the initial start point, the two frequencies have a 100% difference, requiring the lock rotor current to flow (Figure 1, left chart). As the rotor speed increases, the difference between the two frequencies decreases, and the current begins to fall. It does not reach full load current until the rotor speed approaches the rated speed.

By contrast, a VFD starts at the rated slip frequency (2–3 Hz), enabling the rotor to produce constant torque with full-load current. As the drive frequency rises, the voltage proportionally increases, maintaining the rated motor flux at all speeds. (Figure 1, right chart). As the drive frequency increases, the voltage proportionally rises, maintaining rated motor flux and torque across the speed range.

The VFD can produce 100%, 125%, or even 200% of the rated torque at corresponding current levels, up to approximately 80% of the motor’s breakdown torque. Beyond that point, the current rises rapidly.

Figure 1: Current and torque characteristics for across-the-line starting versus VFD control.

Practical Tip: Using VFDs reduces mechanical stress on motors and connected equipment during startup, extending equipment life while improving energy efficiency.

What is the weakest link in VFD components? How can better specifications mitigate this weak link?

The weakest link in a variable frequency drive is often the DC bus capacitors, rated between 950–1100 VDC. Units below 1000 VDC generally have shorter service lives. Proper specifications for VFD sizing can extend reliability and reduce failures.

To mitigate this, specifications for 575-volt VFDs should be written in either of the following ways:

-

The VFD should be capable of continuous operation with a line voltage up to 15% above the motor’s rated voltage (575V +15%).

-

The drive shall operate continuously from three-phase RMS line voltages ranging from the motor’s rated voltage to 650 volts.

Practical Tip: Specifying higher-quality capacitors and ensuring adequate cooling will improve drive performance, reduce failures, and increase service life.

What are the key considerations for single-to-three-phase conversion using VFDs?

When using a three-phase rated VFD on single-phase power, the unit must be oversized because single-phase current is 1.732 times higher than the motor’s three-phase rating. Properly matching the electric motor design with the drive is essential for safe conversion and performance. The solution is to size the drive at roughly double the motor’s full load amps (FLA).

For example, a 10 HP, 25.5-ampere three-phase motor at 230 VAC on a single-phase 208 V supply requires a VFD with a continuous output capacity of at least 51 amps. However, since the VFD can only output 193 V three-phase at 208 V, a step-up transformer (208 V to 240 V) is required to maintain voltage within the motor’s ±10% tolerance.

Practical Tip: Always verify both current and voltage requirements when converting from single-phase to three-phase with VFDs to avoid derating motor performance.

What is the typical harmonic spectrum from VFDs?

VFDs are nonlinear loads that distort current waveforms. For three-phase units, harmonics occur at 6n ± 1 (5th, 7th, 11th, 13th, …). For single-phase units, they occur at 4n ± 1 (3rd, 5th, 7th, 9th, …). This distortion affects overall motor performance and power quality.

Harmonics can be analyzed with the Fourier transformation, which breaks distorted waveforms into sums of pure sine waves. Mitigation strategies include line reactors, harmonic filters, or advanced rectifier designs.

-

For three-phase VFDs (six rectifiers), harmonics occur at 6n ± 1 (5th, 7th, 11th, 13th, 17th, 19th …).

-

For single-phase VFDs (four rectifiers), harmonics occur at 4n ± 1 (3rd, 5th, 7th, 9th, 11th …).

Figure 2: Odd Harmonics signals superimposed, 1st, 3rd, 5th, 7th, 9th, 11th and 13th

Figure 3: Current Waveform and the Fourier Harmonic Breakdown

The French mathematician Fourier demonstrated that distorted waveforms can be expressed as the sum of many sine waves of different frequencies and magnitudes, a concept now known as the Fourier transformation.

Practical Tip: Harmonic distortion can be mitigated with line reactors, harmonic filters, or 12-pulse rectifier designs to protect power quality and improve motor efficiency.

The above odd harmonics, with the inverse for their magnitude being added, will make a pure square sine wave if we add all the odd harmonics together. A mathematician named Fourier developed a relationship between a non-sinusoidal signal and a series of pure sine waves of different magnitudes to represent the distorted waveform. This is known as the Fourier transformation.

Why are motors rated at 230, 460 and 575 Volts and not at 240, 480 and 600 Volts?

NEMA motors are rated slightly below system voltage to account for real-world voltage drops. Since torque output is proportional to voltage squared, a 5% reduction in voltage results in a torque reduction of approximately 10%. Proper motor overload protection ensures reliability across varying supply conditions.

Practical Tip: Always verify nameplate ratings against the supply voltage to ensure optimal motor efficiency and drive performance.

Figure 4: How motor torque and performance vary with system voltage.

Why does the VFD seem to behave differently when it is operated on the standby generator?

Generators have higher impedance and weaker frequency regulation compared to utility power. The rapid response of a VFD in motor control can conflict with the slower response of the generator, resulting in instability, surges, and distorted voltage waveforms. Adjusting VFD programming (e.g., acceleration and deceleration times) can improve stability when operating on backup power systems.

The second issue is that generator impedance amplifies harmonic distortion. This flattens voltage waveforms at the VFD terminals, affecting not only the drive but all connected loads.

Practical Tip: Increasing VFD acceleration and deceleration times, as well as using filters, can help reduce instability when operating drives on standby generators.

Figure 5: VFD interaction with generator impedance and resulting waveform distortion.

Understanding electric motors and drives is critical for optimizing system efficiency and reliability. VFDs enhance synchronous motors, variable frequency drive in HVAC systems, and industrial applications, but they require correct VFD training and specification.

Related Articles

VFD Sizing: The main onsiderations

VFD sizing matches a drive’s current rating to motor amperage. Consider load type, torque demands, and conditions to choose a drive that prevents overheating and ensures long-term motor performance.

Quick Definition: VFD Sizing

-

✅ Definition: The process of selecting a Variable Frequency Drive (VFD) that matches the motor's electrical and operational requirements.

-

✅ Key Considerations: Motor full-load amperage, application type (constant or variable torque), overload capacity, and environmental conditions.

-

✅ Importance: Proper VFD sizing prevents equipment damage, ensures energy efficiency, and extends the lifespan of both the motor and the drive.

Proper VFD sizing is critical to ensure optimal motor performance, energy efficiency, and equipment protection. When sizing a Variable Frequency Drive (VFD), it is essential to consider the motor's full-load amperage, the application type, overload requirements, and environmental factors. Selecting a correctly sized Variable Frequency Drive prevents overheating, improves system reliability, and maximizes the lifespan of both the drive and the motor. When considering Variable Frequency Drive sizing, it's important also to understand how different VFD drives operate and the impact they have on motor control performance.

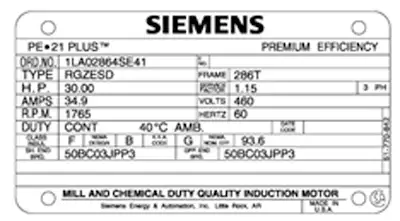

When selecting a Variable Frequency Drive, it’s essential to match the drive’s current rating to the motor’s full load amps (FLA) as listed on the motor nameplate. The horsepower (hp) rating alone is not enough, because different motors with the same hp can have varying current requirements based on efficiency, design, and application. Always use the motor nameplate data for accurate sizing to ensure the Variable Frequency Drive can handle the full operational load without overheating or tripping during normal operation.

In VFD Sizing, the main considerations are:

1. The Variable Frequency Drive continuous current shall be higher than the motor’s current at maximum load. It is not necessary to size the Variable Frequency Drive to the motor Full Load Amps (FLA) rating if the motor application is oversized. A motor that operates under worst-case conditions at 80% FLA current flowing only requires a Variable Frequency Drive that can continuously supply this 80% current value.

2. For Variable Torque Applications, the intermittent current shall be 115% greater than the motor current rating for the worst case starting scenario. If the motor rated current is 65 amperes, then the intermittent current rating should be greater than 74.8 amperes (65A x 115%).

For Constant Torque Application, the intermittent current shall be 150 to 200% of the motor rated current. The equipment OEM can provide the actual worst-case starting torque that they would normally expect for the application. By ensuring that the intermittent current capability of the Variable Frequency Drive is higher than this value, the ac drive will produce sufficient torque to start the HP motor under abnormal situations. Accurate VFD programming ensures that a properly sized drive operates within the correct voltage and current limits, protecting connected equipment.

3. The single-phase input voltage tolerance rating for the Variable Frequency Drive shall be higher than the highest line voltage and lower than the lowest line voltage that lasts longer than two seconds in the facility. Variable Frequency Drives have a 100% voltage rating of 200, 230, 460 or 575 Volts. Each site has different high and low line levels that the Variable Frequency Drive must be able to safely operate at without being damaged. If the measured low line voltage is 550 volts and the high line voltage is 625 volts, then we need a 575-volt-rated Variable Frequency Drive with a voltage tolerance of 575 volts plus 10.9% (625 volts), minus 4.6% (550 volts), or greater. Actual common tolerance values for Variable Frequency Drives are as follows: -5 %, 10%, 12%, 15%, and 20%. Some 575v commercial-rated Variable Frequency Drives are 575v +5%, -10% (518v to 603v), whereas an industrial-rated Variable Frequency Drive may be rated 575v +/- 15% (489v to 660v). If the tolerance rating of the Variable Frequency Drive does not meet the high-line actual site voltage condition, then the Variable Frequency Drive is subject to potential catastrophic failure. In some cases, a frequency converter may be necessary in conjunction with a Variable Frequency Drive to manage input or output frequencies that affect proper sizing.

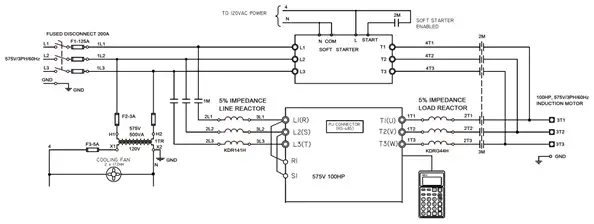

Other Variable Frequency Drive equipment to be upgraded or changed:

Many factors need to be considered when conducting Variable Frequency Drive Sizing in an existing application:

-

Is the existing motor suitable for the speed range, and is the insulation designed to withstand the dv/dt stress caused by the fast switching of the voltage pulses to the motor? If not, use a NEMA MG1 Part 31 designed motor.

-

All VFD manufacturers recommend replacing the motor feeder cable with a shielded, symmetrical cable for the Variable Frequency Drive.

Motor specifications:

In North America, NEMA MG1 standards are used to specify motors. In 1992, a new section (Part 31) was added to specifically address the motor design requirements to work on a Variable Frequency Drive application without installing motor feeder filtering. The original Part 30 design motor nameplate specification allowed for Variable Frequency Drive (VFD) operation if properly sized motor filters were installed in the VFD package.

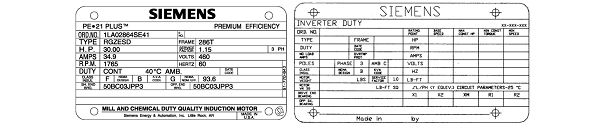

Figure 1: NEMA Part 30 & 31 Nameplates

Since each application required a custom-engineered solution for the proper selection of motor filters, most users and Variable Frequency Drive distributors were not qualified to select the filters properly, thereby increasing the risk of a successful filter selection. By installing the NEMA MG1 Part 31 designed motor, there is no requirement to install a motor filter. The deletion of the requirement for a motor filter typically offsets the slight cost increase associated with the Part 31 motor. The Part 31 motor has an enhanced nameplate that provides motor performance data when the motor is operated at the lowest operating speed, the base 60Hz speed, and the highest speed above 60Hz.

System component used with Variable Frequency Drives:

Many factors are required when the decision for installing a Variable Frequency Drive is made: The Variable Frequency Drive solution should be supplied with all the necessary equipment to provide for a long life and reliable Variable Frequency Drive solution:

-

Circuit Breaker,

-

Transient Surge Protection,

-

Line Filtering, Harmonics and Power Factor

-

Standard or High-Performance Variable Frequency Drive chassis, as needed for the application.

-

VFD cable

-

NEMA MG1 Part 31 motor should always be used

-

Ambient Temperature

-

Derating the VFD

Figure 2: Circuit breaker, MOVs, Reactor, Harmonic Filter, and Variable Frequency Drive Cable

For Variable Frequency Drives used in building systems, review the special considerations outlined in Variable Frequency Drive HVAC applications.

Related Variable Frequency Drives Articles:

VFD Programming: Crucial For Motor Control

VFD programming configures variable frequency drives for motor control, optimizing torque, acceleration, and energy efficiency. Proper setup ensures reliable performance, reduced downtime, and tailored operation in industrial and HVAC systems.

What is VFD Programming?

VFD Programming is the process of setting parameters in variable frequency drives to regulate motor performance, efficiency, and safety.

✅ Adjusts speed, torque, and acceleration profiles

✅ Enhances motor efficiency and reduces energy use

✅ Improves reliability, safety, and process control

Electric Motor Testing Training

Request a Free Training Quotation

In industrial applications, Variable Frequency Drive (VFD) programming plays a crucial role in motor control and energy efficiency. VFD programming involves configuring and optimizing the settings of a VFD to achieve desired motor performance and reduce energy consumption. With the right programming techniques, users can remotely control motor speed, improve energy efficiency, and leverage common VFD communication protocols for seamless operation.

The VFD service industry has long faced a safety dilemma. Traditionally, VFDs with a high arc flash risk potential were housed within the same cabinet as live 600-volt power. This dangerous combination required technicians to wear protective clothing when programming the VFD, increasing the risk of accidents due to limited dexterity and poor visibility. Fortunately, innovations like the JZB1000 MCC by Higrid Power Corp. have mitigated these risks by isolating the VFD from high-energy power sources. Effective VFD programming depends on understanding the fundamentals of electric motor control and how drives regulate torque, speed, and efficiency.

When programming a VFD, careful adjustment of acceleration and deceleration times is essential for smooth operation in applications that require precise control, such as fans and pumps. Proper use of digital and analog input signals enables operators to fine-tune speed settings according to the motor's rated values, ensuring both efficiency and protection. These parameters directly influence how the drive manages the motor's starting and stopping, minimizing stress on the equipment while extending its service life.

Figure 1. Typical VFD with 30 to 60kA short circuit capability

Key VFD Parameters and Settings

To understand the intricacies, it is essential to become familiar with specific VFD parameters and concepts. These include motor nameplate data, motor overload protection, full-load amperage, and analog inputs. Additionally, technicians should know how to reset the drive to factory or default settings when necessary and be able to navigate parameter numbers to configure the VFD for optimal performance.

Beyond the basics, modern programming requires deeper knowledge of:

-

Control modes: V/Hz scalar control, sensorless vector control, and closed-loop vector control.

-

Carrier frequency and PWM control: Determines switching noise, torque ripple, and harmonic distortion.

-

Acceleration and deceleration ramps: Control how quickly the motor reaches or slows from set speed.

-

Start/stop methods: Coast to stop, soft stop, or controlled braking, including regenerative braking options.

-

Direction control and minimum speed limits: Ensure safe and application-specific operation.

Motor nameplate data is crucial for ensuring proper VFD configuration. The motor's nameplate provides essential information, such as voltage, current, and speed ratings, to determine suitable VFD settings. Motor overload protection is also crucial to prevent damage to the motor due to excessive current or overheating. Full load amperage refers to the current a motor draws when operating at its rated horsepower. At the same time, analog inputs enable remote motor speed control via a proportional signal from an external device. Technicians can optimize energy use by combining VFD programming with efficiency opportunities through motor maintenance for long-term cost savings.

Figure 2. Typical VFD with 30 to 60kA short circuit capability with Draw out isolation

Wiring, Installation, and Environmental Considerations

Proper installation has a direct impact on performance and longevity. Key factors include:

-

Mounting and enclosures: NEMA or IP-rated enclosures protect against dust, moisture, and contaminants.

-

Cooling and ventilation: Adequate airflow prevents overheating.

-

Cable routing: Long motor leads can create voltage spikes, requiring dV/dt filters or output reactors.

-

Grounding and shielding: Essential to minimize electromagnetic interference.

-

Control wiring: Proper connections for digital inputs, analog signals, or communication protocols like Modbus, Profibus, or Ethernet/IP.

Programming a VFD requires accurate motor data, which is why knowledge of electric motor design and electric motor efficiency is essential.

Safety Enhancements

The JZB1000 MCC features two design versions that eliminate arc flash incidents during coding. In the first version, the complete VFD and necessary options are mounted in a draw-out unit that can be disconnected from the vertical bus. A low-energy control power supply, typically 24VDC or AC, powers up the microprocessor and keypad while the unit is physically disconnected from the 600-volt bus. This setup allows technicians to program the VFD safely without needing face shields or gloves. For safe and reliable operation, VFD parameters should always be set with proper motor overload protection in mind.

The second version also features a draw-out cell but utilizes a separate cell for the fused switch or circuit breaker. Once this feeder cell is padlocked in the disconnected position, the arc flash risk is reduced.

Additional safety functions include Safe Torque Off (STO), ground fault protection, thermal protection, and interlocks that ensure safer maintenance and operation.

Advanced Applications

Different loads demand different programming approaches:

-

Pumps and fans: Utilize PID loops and variable speed control for enhanced energy efficiency.

-

Conveyors: Require precise torque and acceleration control to avoid product damage.

-

Compressors: Benefit from soft start/stop to minimize mechanical stress.

-

Flying start: Enables the VFD to catch a motor that is already spinning.

By optimizing these advanced settings, technicians can tailor drive performance to specific industrial applications.

If you’re new to drives, learning how a VFD works provides the foundation for understanding more advanced VFD drives programming techniques.

Troubleshooting, Fault Codes, and Maintenance

Common VFD faults include overvoltage, undervoltage, overcurrent, ground faults, and motor overheating. Proper programming and monitoring help minimize these issues.

Maintenance practices should include:

-

Regular inspection and cleaning to prevent dust buildup.

-

Checking cooling fans and filters.

-

Monitoring diagnostic data (motor vibration, current, and temperature).

-

Updating firmware and reviewing fault logs.

In building systems, variable frequency drive HVAC programming shows how tailored drive settings can maximize comfort while lowering energy use.

Real-World Benefits and Energy Savings

The numerous benefits include energy savings, remote motor speed control, and improved motor performance. By optimizing the VFD parameters, technicians can ensure the motor operates at the most efficient point on its torque-speed curve, resulting in substantial energy savings and lower operating costs. Payback periods are often achieved within two to three years due to reduced power bills and extended equipment life.

Moreover, with modern VFD communication protocols, users can remotely monitor and control motor speed, adding flexibility to industrial operations. Comparative studies show that while soft starters provide reduced inrush current, VFDs deliver continuous energy efficiency, torque control, and diagnostic feedback.

It is an essential skill in the industrial sector. With innovations like the JZB1000 MCC, technicians can program VFDs more safely while understanding key parameters and concepts that will ensure optimal motor performance and energy efficiency. Whether you're an experienced engineer or new to VFDs, mastering these skills will undoubtedly prove invaluable in today's demanding industrial landscape. To apply this knowledge in real projects, variable frequency drive training courses expand skills in commissioning, VFD sizing, and practical programming.

Related Articles