What is Switchgear?

By R.W. Hurst, Editor

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Switchgear is an electrical device that controls, protects, and isolates power systems. It includes circuit breakers, fuses, and disconnect switches to manage current flow and ensure system safety. Used in substations and industrial plants, switchgear supports reliable power distribution.

What is Switchgear?

Switchgear refers to electrical equipment used to manage, protect, and isolate electrical circuits in power systems.

✅ Controls and isolates electrical circuits in substations and industrial facilities

✅ Includes devices like circuit breakers, fuses, and disconnect switches

✅ Ensures safety, reliability, and efficiency in power distribution

Basic Protection Relay Training

Request a Free Training Quotation

Switchgear plays a vital role in electrical power systems by providing protection, control, and isolation for electrical equipment. It is essential to understand the different types, their components, and how they are designed and manufactured to ensure the safety and reliability of power systems. Regular testing and maintenance are necessary to keep it in optimal condition and prevent potential issues that could impact the electrical system's performance. To better understand how it contributes to system safety, explore our detailed guide on electrical protection, which outlines essential strategies for fault management and reliability.

Switchgear plays a vital role in circuit protection by managing the flow of electricity through electrical panels, ensuring safe operation across commercial and industrial systems. It enables the isolation of faulty circuits, allowing maintenance work to be performed without disrupting the entire power supply. By integrating components like disconnects, circuit breakers, fuses, and protective relays, switchgear provides reliable fault detection and interruption. Whether installed in substations, motor control centers, or distribution networks, this equipment safeguards transformers, conductors, and other critical infrastructure. Properly maintained switchgear enhances operational efficiency, supports load management, and ensures compliance with electrical safety standards.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

The purpose of switchgear in an electrical system is to protect electrical equipment from damage due to overloads, short circuits, or other electrical faults. It does this by interrupting the flow of electrical current when abnormal conditions are detected. In addition, it helps manage the power supply, isolate faulty sections of an electrical circuit, and enable maintenance work to be carried out safely. Discover how arc fault interrupter breakers play a critical role in modern electrical protection systems to prevent fire hazards caused by arc faults.

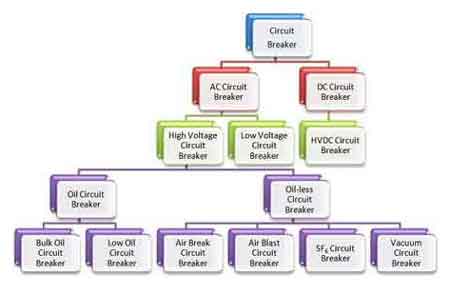

Several types can be classified based on their voltage levels: high voltage switchgears, medium voltage switchgear, and low voltage. HV types is used in power transmission systems and is designed to handle voltages above 36 kV. Medium voltage types are designed for voltages between 1 and 36 kV and are commonly used in distribution networks. On the other hand, low-voltage ones are designed for voltages up to 1 kV and are typically used in industrial and commercial applications. Learn how different circuit breaker types function and why they are a required evolution in overcurrent and arc fault safety.

Different types also vary in terms of their design and construction. However, some common types include air-insulated, gas-insulated, and vacuum circuit breakers. Air-insulated ones use air as the insulating medium, while gas-insulated ones use sulphur hexafluoride (SF6) gas for insulation. Vacuum circuit breakers, a type of medium voltage gear, utilize vacuum technology to interrupt the flow of electrical current.

Comparison of Switchgear Types

| Type | Voltage Range | Insulation Medium | Key Components | Applications |

|---|---|---|---|---|

| Low Voltage (LV) | Up to 1 kV | Air | MCCBs, MCBs, fuses, relays | Commercial buildings, light industrial loads |

| Medium Voltage (MV) | 1 kV to 36 kV | Air, Vacuum, SF6 Gas | Vacuum breakers, relays, CTs, VTs | Industrial plants, utility substations, hospitals |

| High Voltage (HV) | Above 36 kV | SF6 Gas, Oil, Air | GIS, oil circuit breakers, disconnect switches | Transmission networks, power stations |

Components include switches, fuses, circuit breakers, control panels, and protection switchgear such as relays and current transformers. These components work together to ensure the safe and efficient operation of the electrical system. The main components of protection systems are circuit breakers or switches, which interrupt the flow of electrical current when necessary. Fuses and switchgear provide additional layers of protection by detecting and responding to abnormal conditions, such as overloads or short circuits.

One of the critical aspects of design is the metal enclosure that houses the components. This enclosure provides a physical barrier to protect the equipment and personnel from electrical hazards and any potential arc flash incidents. Therefore, the choice of materials and the enclosure's design significantly determine its overall performance, safety, and reliability.

Manufacturing involves a series of processes, including the design, fabrication, assembly, and testing of various components. First, the design phase involves the creation of detailed drawings and specifications based on the requirements of the electrical system. Next, the parts are manufactured and assembled according to the design specifications. Finally, the deviceundergoes rigorous testing to ensure it meets safety and performance standards.

Switchgear testing and maintenance are essential for ensuring the reliability and safety of the electrical system. Some common testing procedures include insulation resistance testing, contact resistance testing, and high voltage withstand testing. These tests help identify potential issues and verify their performance under various conditions. In addition, regular maintenance, such as cleaning, lubrication, and inspection of components, helps prolong the service life of the switchgear and minimize the risk of failure. Accurate fault current calculation is essential for specifying the right switchgear rating and ensuring short-circuit protection is properly designed.

Comparison of Insulation Methods

| Insulation Type | Medium | Advantages | Disadvantages |

|---|---|---|---|

| Air-Insulated (AIS) | Air | Simple, low cost, easy maintenance | Larger size, susceptible to environmental effects |

| Gas-Insulated (GIS) | SF6 Gas | Compact design, high reliability, arc suppression | High cost, SF6 is a potent greenhouse gas |

| Vacuum Insulated | Vacuum | Minimal environmental impact, excellent arc quenching | Limited to medium voltage only |

Frequently Asked Questions

What is switchgear and how is it different from a circuit breaker?

Switchgear and circuit breakers are closely related but serve distinct functions within an electrical system.

It is a broader term for assembling various electrical components, including circuit breakers, switches, fuses, control panels, and switchgear such as relays and current transformers. The primary purpose is to protect, control, and isolate electrical equipment in power systems, ensuring the efficient distribution of electricity and the safety of the electrical network.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

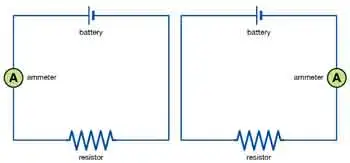

On the other hand, a circuit breaker is a specific component found within the switchgear. An automatic electrical switch protects electrical circuits from damage caused by overloads, short circuits, or other electrical faults. When a fault is detected, the circuit breaker interrupts the flow of electrical current, preventing damage to the equipment and reducing the risk of electrical fires or other hazards. Circuit breakers come in various types, such as air, vacuum, and gas-insulated, depending on the voltage level and application. Learn how short circuit protection systems, including current-limiting fuses and circuit breakers, are integrated into switchgear to prevent catastrophic failures.

Is switchgear AC or DC?

It can be designed for AC (alternating current) and DC (direct current) electrical systems. The choice of AC or DC switchgear depends on the specific application and the type of electrical system it will use.

AC switchgear is commonly used in power generation, transmission line networks, and distribution systems, as most of the world's electrical grids operate on AC. AC switchgear is designed to handle alternating current, where the flow of electricity changes direction periodically. It is used in residential, commercial, and industrial applications.

On the other hand, DC switchgear is used in situations where direct current is utilized. Direct current flows in a constant direction and is commonly found in applications such as battery energy storage systems, electric vehicles, data centers, and renewable energy systems (e.g., solar photovoltaic systems). DC switchgear is designed specifically to handle and protect DC electrical systems.

What are the disadvantages?

While it plays a critical role in electrical power systems by providing circuit protection, control, and isolation of electrical equipment, there are some disadvantages associated with its use:

Cost: High-quality models can be expensive, particularly for high voltage and specialized applications. This cost includes the initial purchase and ongoing maintenance, testing, and eventual replacement.

Space requirements: Gear, especially in high voltage applications, can be large and require significant space within a substation or electrical room. This can be a challenge in urban areas or other locations where real estate is at a premium.

Maintenance: Regular maintenance is crucial for ensuring the reliability and safety. This can involve inspection, cleaning, lubrication, and testing, which may require specialized personnel and equipment. Neglecting maintenance can result in reduced performance and an increased risk of failure.

Environmental impact: Some types, particularly older models and those using SF6 gas for insulation, can have a negative environmental impact. SF6 is a potent greenhouse gas, and leaks can contribute to climate change. Newer, more environmentally friendly switchgear designs are now available, but transitioning to these options may involve additional costs.

Arc flash hazard: An arc flash is a dangerous electrical event that can occur in switchgear due to a fault or short circuit. It can cause significant damage to equipment and pose a serious risk to personnel working nearby. Proper design, maintenance, and safety procedures are essential for minimizing the risk of arc flash incidents.

Despite these disadvantages, switchgear remains an essential component of electrical power systems due to its vital role in protecting and controlling electrical equipment. Many of these disadvantages can be mitigated by selecting the appropriate type and size for the application, ensuring proper installation and maintenance, and adhering to safety protocols.

What is the difference between control gear and switchgear?

Control gear and switchgear are important components in electrical systems, but they have different purposes and distinct functions. Switchgear often works alongside protective relays, which detect abnormal conditions and trigger safe system shutdowns.

Switchgear is a collection of electrical devices that protect, control, and isolate electrical equipment in power systems. It ensures the efficient distribution of electricity and the safety of the electrical network. It typically includes circuit breakers, switches, fuses, and circuit protection devices like relays and current transformers. The primary function is to detect and interrupt the flow of electrical current in case of a fault, such as an overload, short circuit, or other abnormal conditions.

Control gear, conversely, refers to the components and devices used to control and regulate the operation of electrical equipment, such as motors, pumps, and other machinery. Control gear includes components like contactors, motor starters, variable frequency drives, and programmable logic controllers (PLCs). The main function of the control gear is to start, stop, and control the operation of electrical equipment based on predefined parameters, ensuring optimal performance and energy efficiency.

Related Pages