Generator Step Up Transformer

By Harold WIlliams, Associate Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

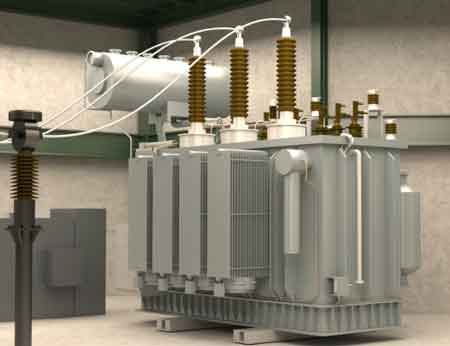

A Generator step up transformer increases the generator output voltage to transmission levels, supporting power plants, substations, and grid integration. It enhances efficiency, minimizes losses, and stabilizes electrical systems in both generation and distribution networks.

What is a Generator Step Up Transformer?

A generator step up transformer (GSU) raises voltage from a generator to transmission levels for efficient long-distance power delivery.

✅ Boosts generator voltage for grid integration

✅ Enhances efficiency and reduces transmission losses

✅ Supports power plants and substations in electrical systems

A GSU is a critical component in modern power systems, acting as the vital link between electricity generation and its efficient transmission across long distances. For electrical professionals, understanding the intricacies of GSUs is essential for ensuring reliable power delivery and maintaining the stability of the power grid. This article explores the fundamental principles, design variations, and maintenance aspects of GSUs, offering valuable insights into their role in power generation, transmission, and distribution. By exploring topics such as voltage ratings, cooling systems, insulation, and testing procedures, readers will gain a comprehensive understanding of these essential power transformers and their crucial role in ensuring the reliable operation of electrical infrastructure. To optimize performance and minimize heat losses in GSUs, it’s essential to understand transformer losses and their impact on efficiency across the grid.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Power Generation and GSUs

GSUs are essential components in a wide variety of power generation schemes. Whether it's a conventional thermal power plant fueled by coal or gas, a nuclear power station, or a renewable energy facility harnessing the power of wind, solar, or hydro, GSUs play a crucial role in preparing the generated electricity for transmission. The generator voltage produced by these power sources typically falls within the range of 13 kV to 25 kV. While sufficient for local distribution within the power plant, this voltage level is too low for efficient transmission over long distances due to the inherent resistance of transmission lines. This is where GSUs come in, stepping up the voltage to much higher levels, often reaching hundreds of kilovolts, to facilitate efficient power delivery across the power grid. In environments where oil-filled designs are impractical, dry-type transformers provide an alternative solution for reliable operation.

Test Your Knowledge About Electrical Transformers!

Think you know Electrical Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Transmission & Distribution

The high voltage output from the GSU transformer is fed into the transmission lines that form the backbone of the power grid. These high-voltage transmission lines enable the efficient long-distance transportation of electricity with minimal losses. By increasing the voltage, the current is reduced, which in turn minimizes the energy lost as heat in the transmission lines. This efficient transmission system ensures that electricity generated at power plants can be reliably delivered to distant cities and towns. While GSUs increase voltage, step down transformers perform the opposite function, reducing voltage levels for distribution and end-user applications.

Transformer Design & Technology

GSU transformers are engineered to withstand the demanding conditions of continuous operation and high voltage levels. They are typically large, custom-built units with robust designs to handle the immense electrical stresses and thermal loads. Different design considerations, such as core and shell types, cooling methods (oil-filled or dry-type), and insulation materials, are crucial to ensure the transformer's long-term reliability and performance within the power grid. For metering and protection alongside GSUs, instrument transformers such as CTs and PTs ensure accurate monitoring and safety.

Reliability & Maintenance

Given their critical role in the power system, the reliability of GSUs is paramount. Regular maintenance, condition monitoring, and diagnostic testing are essential to ensure their continued operation and prevent costly outages. Utilities and power plant operators employ various techniques to assess the health of these transformers, including analyzing oil samples, monitoring temperature and vibration levels, and performing electrical tests. These proactive measures help to identify potential issues before they lead to failures and disruptions in power supply. Similar in importance, a current transformer is designed to safely measure high currents in power plants and substations where GSUs are operating.

Efficiency & Losses

While GSUs are designed for high efficiency, some energy losses are inevitable. These losses occur primarily in the core and windings of the transformer and are influenced by factors such as the core material, winding configuration, and load conditions. Minimizing these losses is crucial for overall system efficiency and reducing operating costs. Transformer manufacturers continually strive to enhance efficiency by utilizing advanced materials, optimizing designs, and implementing innovative cooling systems.

Cooling Systems

Effective cooling is crucial for the reliable operation of GSUs, especially given their high operating loads. Various cooling methods are employed, including Oil Natural Air Natural (ONAN), Oil Natural Air Forced (ONAF), Oil Forced Air Forced (OFAF), and Oil Directed Water Forced (ODWF). These methods employ various combinations of natural and forced circulation of oil and air, or water, to dissipate heat and maintain optimal operating temperatures within the transformer.

Insulation & Dielectric Strength

The high voltage levels present in GSUs necessitate robust insulation systems to prevent short circuits and ensure safe operation. The insulation materials used in these transformers must have high dielectric strength to withstand the electrical stresses. Factors such as voltage levels, temperature, and environmental conditions influence the choice of insulation materials and the design of the insulation system. While GSUs raise generator voltage for transmission, a control transformer provides stable, lower-level power for control circuits and equipment.

Frequently Asked Questions

Why is a GSU used in a power plant?

Step-up transformers are used in power plants because they increase the voltage of the electricity generated, which is necessary for efficient long-distance transmission. Higher voltage levels result in lower current, which minimizes energy losses in the transmission lines. This ensures that electricity can be delivered to consumers far from the power plant with minimal losses.

Sign Up for Electricity Forum’s Electrical Transformers Newsletter

Stay informed with our FREE Electrical Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

What is the typical voltage rating of a generator step-up transformer?

The voltage rating of a GSU varies depending on the specific application. However, typical generator voltage ranges from 13 kV to 25 kV, while the secondary voltage (after step-up) can range from 66 kV to 765 kV or even higher for long-distance transmission. The specific voltage levels are determined by factors such as the generator output, the transmission system voltage, and the desired level of efficiency.

What are the different types of generator step-up transformers?

GSUs can be broadly categorized into oil-filled and dry-type transformers. Oil-filled transformers utilize insulating oil for both cooling and insulation, whereas dry-type transformers rely on air or gas insulation. Within these categories, there are further variations in core type (shell or core) and insulation materials. The choice of GSU type depends on factors such as the transformer's size, voltage rating, environmental conditions, and safety considerations.

How does a generator step-up transformer handle surges and overloads?

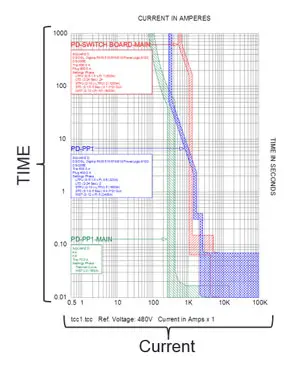

GSUs are designed to withstand temporary surges and overloads that can occur in the power system. They incorporate protective devices such as surge arresters to divert excess voltage caused by events like lightning strikes. Additionally, relays are used to automatically disconnect the transformer in the event of severe faults, such as short circuits, thereby preventing damage to both the transformer and the power system.

What are the key maintenance activities for a generator step-up transformer?

Key maintenance activities for GSUs include:

-

Oil Analysis: Regularly analyzing the insulating oil for signs of degradation or contamination.

-

Visual Inspections: Inspecting the transformer for any physical damage, leaks, or signs of overheating.

-

Electrical Testing: Performing tests like winding resistance measurements and insulation resistance tests to assess the transformer's electrical integrity.

-

Infrared Thermography: Using thermal imaging to detect hot spots that may indicate potential problems.

By adhering to a comprehensive maintenance program, power plant operators can ensure the long-term reliability and performance of their GSU transformers.