Everything Electric Vancouver spotlights EV innovation, electric vehicles, charging infrastructure, battery technology, autonomous driving, and sustainability, with test drives, consumer education, and incentives accelerating mainstream adoption and shaping the future of clean transportation.

Key Points

Everything Electric Vancouver is a premier EV expo for vehicles, charging tech, and clean mobility solutions.

✅ New EV models: better range, battery tech, autonomous features

✅ Focus on charging networks: ultra-fast and home solutions

✅ Consumer education: test drives, incentives, ownership costs

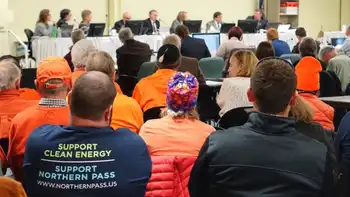

Vancouver has once again become the epicenter of electric vehicle (EV) innovation with the return of the "Everything Electric" event. This prominent showcase, as reported by Driving.ca, highlights the accelerating shift towards electric mobility, echoing momentum seen at the Quebec Electric Vehicle Show and the growing role of EVs in shaping the future of transportation. The event, held at the Vancouver Convention Centre, provided a comprehensive look at the latest advancements in electric vehicles, infrastructure, and technologies, drawing attention from industry experts, enthusiasts, and consumers alike.

A Showcase of Electric Mobility

"Everything Electric" has established itself as a key platform for unveiling new electric vehicles and technologies. This year’s event was no exception, featuring a diverse range of electric vehicles from leading manufacturers. Attendees had the opportunity to explore a wide array of models, from sleek sports cars and luxury sedans to practical SUVs and compact city cars. The showcase underscored the significant progress in EV design, performance, and affordability, reflecting a broader trend towards mainstream adoption of electric mobility.

One of the highlights of this year’s event was the unveiling of several cutting-edge electric models. Automakers used the platform to debut their latest innovations, including enhanced battery technologies, improved range capabilities, and advanced autonomous driving features. This not only demonstrated the rapid evolution of electric vehicles but also underscored the commitment of the automotive industry to addressing environmental concerns and meeting consumer demands for sustainable transportation solutions.

Expanding Charging Infrastructure

Beyond showcasing vehicles, "Everything Electric" also emphasized the critical role of charging infrastructure in supporting the growth of electric mobility. The event featured exhibits on the latest developments in charging technology, including ultra-fast chargers, innovative home charging solutions, and corridor networks such as B.C.'s Electric Highway that connect communities. With the increasing number of electric vehicles on the road, expanding and improving charging infrastructure is essential for ensuring convenience and reducing range anxiety among EV owners.

Industry experts and policymakers discussed strategies for accelerating the deployment of charging stations and integrating them into urban planning, while considering the B.C. Hydro bottleneck projections as demand grows. The event highlighted initiatives aimed at expanding public charging networks, particularly in underserved areas, and improving the overall user experience. As electric vehicles become more prevalent, the development of a robust and accessible charging infrastructure will be crucial for supporting their widespread adoption.

Driving Innovation and Sustainability

"Everything Electric" also served as a platform for discussions on the broader impact of electric vehicles on sustainability and innovation. Panels and presentations explored topics such as the environmental benefits of reducing greenhouse gas emissions, the role of renewable energy in powering EVs, insights from the evolution of U.S. EV charging infrastructure, and advancements in battery recycling and second-life applications. The event underscored the interconnected nature of electric mobility and sustainability, highlighting how innovations in one area can drive progress in others.

The emphasis on sustainability was evident throughout the event, with many exhibitors showcasing eco-friendly technologies and practices. From energy-efficient manufacturing processes to sustainable materials used in vehicle interiors, the event highlighted the automotive industry's efforts to reduce its environmental footprint and contribute to a more sustainable future.

Consumer Engagement and Education

A key aspect of "Everything Electric" was its focus on consumer engagement and education. The event offered test drives and interactive demonstrations, mirroring interest at the Regina EV event as well, allowing attendees to experience firsthand the benefits and performance of electric vehicles. This hands-on approach helped demystify electric mobility for many consumers and provided valuable insights into the practical aspects of owning and operating an EV.

In addition to vehicle demonstrations, the event featured workshops and informational sessions on topics such as EV financing, government incentives, and the benefits of transitioning to electric vehicles, reflecting how EVs in southern Alberta are a growing topic today. These educational opportunities were designed to empower consumers with the knowledge they need to make informed decisions about adopting electric mobility.

Looking Ahead

The successful return of "Everything Electric" to Vancouver highlights the growing importance of electric vehicles in the automotive landscape. As the event demonstrated, the electric vehicle market is rapidly evolving, with new technologies and innovations driving progress towards a more sustainable future. The increased focus on charging infrastructure, sustainability, and consumer education reflects a comprehensive approach to supporting the transition to electric mobility, exemplified by B.C.'s charging expansion across the province.

As Canada continues to advance its climate goals and promote sustainable transportation, events like "Everything Electric" play a crucial role in showcasing the possibilities and driving forward the adoption of electric vehicles. With ongoing advancements and increased consumer interest, the future of electric mobility in Vancouver and beyond looks increasingly promising.

Related News