Dissolved Gas Analysis Of Transformer Oil

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Dissolved Gas Analysis (DGA) is a key diagnostic tool for transformers, evaluating dissolved gases in insulating oil to identify overheating, arcing, partial discharge, and insulation breakdown. It enables predictive maintenance, improves power system reliability.

What is Dissolved Gas Analysis?

Dissolved Gas Analysis is a diagnostic method that evaluates gases in transformer insulating oil to identify electrical faults and ensure reliable operation.

✅ Detects partial discharge, arcing, and overheating

✅ Guides predictive maintenance and fault prevention

✅ Improves transformer reliability and system safety

DGA is a crucial tool for electrical engineering and maintenance professionals, providing vital insights into the health of transformers and other high-voltage assets. By detecting gases produced during insulation degradation or electrical faults, it offers early warning signs of potential failures. Proactive detection through DGA allows utilities and industries to prevent unplanned outages, extend equipment lifespan, and strengthen system reliability. As a cornerstone of condition-based maintenance, mastering DGA is essential for maintaining high-performance electrical infrastructure. Understanding dissolved gas analysis begins with the role of dielectric fluids, as the composition of transformer oil directly influences gas formation and the accuracy of fault detection.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Transformer Fault Diagnosis

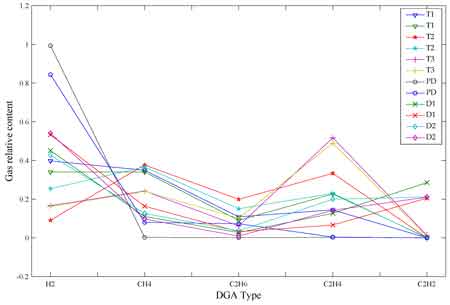

One of the key applications of DGA is transformer fault diagnosis. Under normal operating conditions, only trace gases form. During faults, such as partial discharge or arcing, heat and stress decompose insulating oil and cellulose, generating gases such as hydrogen, methane, ethane, ethylene, acetylene, carbon monoxide, and carbon dioxide.

-

Hydrogen (H₂): partial discharges

-

Methane (CH₄): low-temperature overheating of cellulose

-

Ethane (C₂H₆) and Ethylene (C₂H₄): higher-temperature thermal faults

-

Acetylene (C₂H₂): arcing

-

CO and CO₂: insulation paper degradation

The concentration and ratio of these gases provide a fingerprint of the fault type. Experts can distinguish between thermal faults, partial discharge, and severe arcing, enabling timely maintenance. New research highlights advancements in DGA data quality, improving reliability and reducing errors in transformer fault diagnosis.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Interpretation Methods and Fault Classification

Accurate interpretation is central to DGA. Several methods have been standardized:

-

Ratio Methods: Rogers and Doernenburg use gas concentration ratios to classify fault types.

-

Duval Triangle / Pentagon: graphical techniques plotting gas ratios (e.g., H₂:CH₄:C₂H₆) to identify fault zones (partial discharge, low/high thermal faults, arcing).

-

IEC 60599 and IEEE C57.104 Standards: provide threshold limits, diagnostic ratios, and guidelines for reporting and action.

Example: Using the Duval Triangle, a mixture rich in acetylene indicates arcing, while high ethylene levels suggest a high-temperature thermal fault.

Emerging methods, such as fuzzy logic and expert systems, refine interpretation when faults overlap, thereby enhancing the accuracy of fault detection. AI and machine learning now enhance accuracy, reducing misclassification in complex cases. Engineers applying DGA can benefit from recent advancements in dissolved gas analysis, which refine fault classification methods through better interpretation of gas ratios.

Case Study Example

A 230 kV transformer recorded abnormal gas levels:

-

H₂ = 750 ppm

-

CH₄ = 120 ppm

-

C₂H₆ = 40 ppm

-

C₂H₄ = 260 ppm

-

C₂H₂ = 15 ppm

-

CO = 900 ppm

Interpretation: The high hydrogen, ethylene, and carbon monoxide levels suggest a high-temperature thermal fault with cellulose insulation degradation. Using the Duval Triangle, this case falls into a “thermal fault >700°C” zone. Preventive maintenance avoided catastrophic failure. Specialists often review the CO/CO₂ ratio in dissolved gas analysis, since carbon gases provide unique insights into cellulose insulation degradation.

Predictive Maintenance

Predictive maintenance is another significant advantage of DGA. Since transformers are essential but costly assets, unplanned downtime can be financially devastating. Through DGA, utilities and industrial operators can predict when maintenance is required, rather than reacting to sudden failures. DGA monitors provide real-time tracking of gas concentrations, enabling maintenance teams to act before a minor issue becomes a major outage.

DGA shifts maintenance from a reactive to a predictive approach. By monitoring gas concentration trends, utilities can:

-

Predict when interventions are needed

-

Extend transformer service life

-

Reduce operational costs and outages

Continuous monitoring ensures that problems are addressed before they escalate into system failures. By pairing dissolved gas analysis with condition monitoring in an age of modernization, utilities can transition from reactive repairs to predictive maintenance strategies.

Gas Chromatography

DGA relies on gas chromatography, which separates and quantifies individual gases. A sample of insulating oil is processed to measure the concentrations of hydrogen, methane, ethane, ethylene, acetylene, carbon monoxide, and carbon dioxide in parts per million (ppm). This precision enables consistent results across laboratories and forms the foundation of DGA reporting. Gas concentrations revealed through DGA provide insights that complement power transformer health check programs, ensuring reliable performance of these critical assets.

IEC Standards and Key Gases

International Electrotechnical Commission (IEC) standards play a pivotal role in ensuring consistency and accuracy in dissolved gas analysis. These standards provide guidelines for the collection, handling, and analysis of oil samples, as well as for the interpretation of results. By following IEC standards, utilities and maintenance teams can achieve more reliable and comparable DGA results across different transformers and facilities. This uniformity helps ensure that decisions regarding maintenance and repair are based on accurate, standardized data.

Key gases such as hydrogen, methane, ethane, ethylene, and acetylene are essential to understanding the types of transformer faults. For example, the presence of acetylene often points to arcing, while ethylene and ethane are indicators of high-temperature thermal faults. Hydrogen is commonly associated with partial discharge, while methane is linked to overheating of cellulose insulation. Recognizing the role of these key gases allows technicians to identify specific transformer problems, prioritize maintenance, and avoid costly failures.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

International standards ensure consistency.

-

IEC 60599: guidance on sampling, analysis, and interpretation.

-

IEEE C57.104: fault classification tables and gas thresholds.

Example gas thresholds (ppm):

| Gas | Normal | Caution | Dangerous |

|---|---|---|---|

| Hydrogen (H₂) | <100 | 100–700 | >700 |

| Acetylene (C₂H₂) | <1 | 1–10 | >10 |

| Ethylene (C₂H₄) | <50 | 50–200 | >200 |

Limitations and Caveats

While powerful, DGA has limits:

-

Cannot localize the exact fault location

-

Oil replacement can reset the gas history

-

Mixed faults produce ambiguous results

-

Stray gassing may occur at low temperatures

-

Sampling and handling errors can skew results

DGA should complement other diagnostics, such as dissolved moisture analysis, partial discharge monitoring, or infrared thermography. Dissolved gas analysis also supports the broader maintenance of substation transformers, where continuous monitoring is essential to preventing costly power disruptions.

Real-Time Monitoring

DGA monitors are essential tools for continuous tracking of gas levels in transformer oil. Unlike periodic sampling, DGA monitors operate in real-time, offering immediate insight into any changes in dissolved gases. By continuously observing gas concentrations, operators gain a deeper understanding of the transformer's condition, enabling swift responses to abnormal readings. Continuous tracking helps utilities maintain system reliability and prevent emergency shutdowns.

Online DGA monitors provide continuous tracking of gas levels, feeding data into SCADA and asset management systems. Unlike periodic lab sampling, online systems detect rapid changes, offering:

-

24/7 protection for critical transformers

-

Faster fault detection and intervention

-

Integration with predictive analytics dashboards

Though more costly, real-time systems are invaluable for utilities managing large fleets of high-value transformers.

Advanced Analytics and AI

Recent research applies machine learning and deep learning to improve DGA interpretation. Models such as convolutional neural networks (CNNs), ensemble classifiers, and copula-based correlation methods identify fault patterns with greater accuracy. Studies (2023–2025, Nature, MDPI, arXiv) show AI can detect stray gassing and overlapping fault signatures earlier than classical methods. Combining traditional ratios with AI enhances both precision and reliability.

Frequently Asked Questions

When should transformers be retested with DGA?

Typically, every 6–12 months for routine testing, but more frequently if abnormal gas levels are detected or if online monitors show sudden changes.

How do you choose a DGA monitor?

Consider transformer criticality, cost, required gases, calibration frequency, and SCADA compatibility.

What is the minimum oil sample size?

About 50–100 mL is typically required for laboratory gas chromatography.

What role does cellulose insulation play in gas generation?

Breakdown of cellulose produces CO and CO₂, indicating paper degradation in addition to oil fault gases.

Can DGA predict all failures?

No. While highly effective, it should be combined with other diagnostics for complete transformer condition monitoring.

Related Articles