Vacuum Circuit Breaker Protection

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

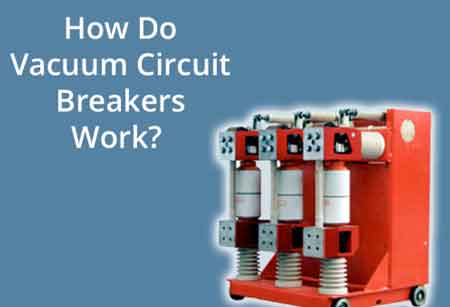

A Vacuum Circuit Breaker interrupts electrical current by extinguishing arcs in a sealed vacuum chamber, providing high-voltage switching, minimal maintenance, enhanced safety, and reliable performance for medium- and high-voltage electrical power systems in industrial and utility applications.

What is a Vacuum Circuit Breaker?

A vacuum circuit breaker (VCB) is an arc-extinguishing device used in medium-voltage power systems. It isolates faults by interrupting the flow of current in a vacuum environment, minimizing arc energy and equipment wear.

✅ Uses a vacuum chamber to extinguish electrical arcs during high-voltage switching

✅ Provides reliable performance and minimal maintenance in power systems

✅ Enhances safety and efficiency in medium- and high-voltage applications

Substation Maintenance Training

Electrical Transformer Maintenance Training

Request a Free Training Quotation

Why Vacuum Circuit Breakers Are Vital in Electrical Power Distribution

Vacuum circuit breaker technology plays a critical role in modern electrical engineering and maintenance, offering a reliable and efficient solution for interrupting electrical currents in medium-voltage power systems. Its ability to quickly extinguish electrical arcs within a vacuum chamber makes it essential for protecting equipment from short circuits, overloads, and voltage spikes. For electrical maintenance professionals, understanding how a VCB works is vital for ensuring system reliability, minimizing downtime, and improving overall operational safety. With its low maintenance needs, long service life, and superior arc-quenching capabilities, the vacuum circuit breaker has become a preferred choice in substations, industrial plants, and commercial power systems. Vacuum circuit breakers are essential components in many electrical substation designs, where medium-voltage protection and arc suppression are critical for reliable power distribution.

One of the key features of a vacuum circuit breaker is its ability to interrupt electrical current during a short circuit or fault condition. Unlike traditional breakers that rely on gas or oil to quench the electric arc, a vacuum interrupter extinguishes the arc in a vacuum environment. This is achieved by using specially designed contact materials and an operating mechanism that allows the contacts to separate quickly, creating a high dielectric strength gap that prevents the arc from re-establishing. The vacuum environment plays a vital role as it has no medium to sustain the arc, ensuring the arc is extinguished rapidly. This capability makes vacuum circuit breakers highly effective in both medium voltage and high voltage systems. Integrating 3D substation design using AutoCAD enables engineers to visualize breaker placement and optimize the layout for VCB maintenance and operation.

Test Your Knowledge About Electrical Substations!

Think you know Electrical Substations? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Common Applications of VCBs in Industrial and Utility Environments

The applications of a vacuum circuit breaker spans multiple sectors. In industrial settings, they are widely used in manufacturing plants, mining operations, and oil and gas facilities. Their ability to handle high fault currents and provide rapid arc interruption ensures minimal downtime and enhanced safety for personnel and equipment. Utility companies use them extensively for power transmission and distribution, particularly in substations where reliability is paramount. Vacuum technology is also being adopted in commercial buildings and data centers to safeguard critical infrastructure. While less common in residential applications, they may be used in specialized installations requiring high performance and minimal maintenance.

Key Advantages of Vacuum Circuit Breakers Over Traditional Switchgear

The advantages over traditional technologies are numerous. They offer superior reliability and require significantly less maintenance. Unlike oil-based or SF6-based breakers, vacuum interrupters do not rely on consumable materials, which reduces the need for frequent servicing. Additionally, vacuum breakers have a compact design, making them easier to install and transport. Their lightweight nature and small footprint are valuable in environments where space is limited. Furthermore, since they do not use SF6 gas—a potent greenhouse gas—vacuum breakers are a more environmentally friendly solution, supporting global sustainability goals. Safety remains a top priority, and VCBs play a key role in adhering to the 6 basic rules of substation safety by quickly interrupting fault currents.

The Arc Interruption Mechanism Behind Vacuum Circuit Breakers

Understanding the working principle reveals the innovative nature of this technology. When a fault occurs, the operating mechanism causes the contacts within the vacuum interrupter to separate. As the contacts pull apart, an electric arc forms between them. However, since the separation occurs in a vacuum, the arc cannot sustain itself. The absence of air or gas to ionize ensures that the arc is extinguished almost instantly. The design of the contact materials and their configuration are critical to achieving this outcome, as they must endure the high thermal stress generated by the arc while maintaining electrical conductivity during normal operation. This sophisticated engineering is what makes vacuum circuit breakers a top choice for modern electrical grids. If you need a broader understanding of how substations function, visit our page on what is an electrical substation.

Types of Vacuum Circuit Breakers: Indoor, Outdoor, and Voltage Ratings

There are several types of vacuum circuit breaker designed for different environments and voltage levels. Indoor vacuum breakers are typically used in controlled environments like substations and industrial plants. Outdoor vacuum breakers, on the other hand, are designed to withstand harsh weather conditions. Voltage ratings for these breakers vary, from low-voltage systems in commercial buildings to medium-voltage and high-voltage installations in power grids. Current ratings also differ depending on the application, with certain models designed to handle higher currents in industrial and utility environments.

Comparison of VCBs with Air, SF₆, and Oil Circuit Breakers

| Feature | Vacuum Circuit Breaker (VCB) | Air Circuit Breaker (ACB) | SF₆ / Oil Circuit Breakers |

|---|---|---|---|

| Arc Medium | Vacuum – no gas or air; fast deionization | Air at atmospheric pressure | SF₆ gas (insulated) / Mineral oil (liquid) |

| Voltage Range | Medium voltage (up to 38–72.5 kV) | Low voltage (up to 1,000 V) | Medium to high voltage (up to 800 kV) |

| Arc Quenching Speed | Very fast | Moderate | Fast / Moderate |

| Maintenance Needs | Very low (sealed interrupters) | High (frequent arc chute maintenance) | Moderate to high (gas/oil handling) |

| Environmental Impact | Environmentally friendly (no gases or oil) | Neutral | Negative (SF₆ is a GHG, oil poses fire risk) |

| Physical Size | Compact and lightweight | Bulky in higher ratings | Compact (SF₆) / Large (Oil) |

| Applications | Substations, industrial plants, commercial use | Buildings, panels, low-voltage distribution | Transmission systems, legacy grids |

| Switching Frequency | High (ideal for frequent operations) | Low to moderate | Medium to low |

| Cost | Moderate | Low | High (SF₆) / Moderate (Oil) |

| Service Life | Long (20–30 years or more) | Shorter lifespan | Long (if maintained) / Shorter (Oil aging) |

Trends Driving Innovation in Vacuum Circuit Breaker Technology

The market for vacuum circuit breaker technology is evolving, driven by emerging trends and technological advancements. One of the most significant developments is the integration of smart grid technology. Vacuum breakers equipped with sensors and digital monitoring systems can provide real-time data on system health, enabling predictive maintenance and reducing the likelihood of unplanned outages. Digitalization is also playing a role in enhancing the operational efficiency of vacuum breakers. Advanced control systems allow for remote operation and diagnostics, making it easier to detect and address issues before they escalate. Proper control of the electrical frequency supply is vital when integrating vacuum breakers into substations with sensitive or fluctuating load conditions.

Another key trend is the industry's focus on sustainability. Vacuum circuit breakers support this initiative by eliminating the use of SF6 gas, which has a high global warming potential. As utilities and industries prioritize greener technologies, vacuum breakers are becoming an integral part of sustainable electrical infrastructure. Efforts to develop energy-efficient designs and reduce the overall environmental impact of electrical equipment are driving innovation in this field. Substations with digital relays or automated systems benefit most from comprehensive analysis, especially during substation automation projects.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Frequently Asked Questions

How does a vacuum breaker work?

A vacuum breaker, also known as a vacuum circuit breaker, operates by interrupting the flow of current using vacuum technology as the medium for arc extinction. When a fault or overload occurs, the breaker separates its contacts inside a sealed vacuum chamber. As the contacts part, an electrical arc is formed. In a vacuum, the arc is quickly extinguished because the ionization of particles in the vacuum is minimal. This process ensures a fast and efficient interruption of the electrical current, preventing damage to electrical equipment and protecting the power system from faults. RTU and HMI redundancy enhances substation automation by ensuring that VCB operation and monitoring remain uninterrupted during system faults.

What is the purpose of VCB?

The primary purpose of a VCB is to protect electrical equipment and power systems from faults such as short circuits, overloads, and voltage spikes. VCBs act as automatic protective devices, isolating the faulty section of the system to prevent the spread of the fault. They ensure the safety of equipment and personnel by quickly cutting off electrical power. VCBs are widely used in medium-voltage systems due to their ability to handle high interrupting capacities with minimal maintenance, compact design, and longer lifespan compared to air or oil circuit breakers.

What is the difference between vacuum and air circuit breakers?

The primary difference between a VCB and an air circuit breaker (ACB) lies in the arc extinguishing medium and the type of application.

Arc Extinguishing Medium:

-

VCB: Uses a vacuum as the arc extinguishing medium. Since a vacuum lacks atmospheric pressure and particles, it suppresses the arc quickly and efficiently.

-

ACB: Uses air at atmospheric pressure as the arc extinguishing medium. When the contacts separate, the arc is extinguished using a combination of cooling, arc chutes, and deionizing plates.

Speed of Operation:

-

VCB: Faster arc extinction due to the rapid deionization in a vacuum, making it suitable for medium-voltage applications.

-

ACB: Slower than VCB in terms of arc extinction, typically used for low-voltage power distribution.

Maintenance and Durability:

-

VCB: Requires less maintenance due to the vacuum chamber's sealed design, which prevents contamination from dust and moisture.

-

ACB: Requires more frequent maintenance since air-based systems are exposed to environmental factors and wear of arc chutes.

Application:

-

VCB: Used in medium-voltage systems (typically 11 kV to 33 kV) for industrial, utility, and commercial applications.

-

ACB: Used in low-voltage systems (up to 1,000 V) for buildings, switchboards, and electrical panels.

Can a vacuum trip a breaker?

No, a vacuum itself does not trip a breaker. The term "vacuum" in a Vacuum Circuit Breaker refers to the medium in which the arc is extinguished, not the mechanism for tripping the breaker. The breaker trips when a protective relay detects an overcurrent, short circuit, or other fault condition. Once the relay sends a trip signal, the operating mechanism of the vacuum circuit breaker activates, causing the contacts to open inside the vacuum chamber. The vacuum allows for quick and efficient arc extinction, but it does not initiate the tripping action. Learn more about how safe circuit breakers, like VCBs, are shaping the future of substation reliability and operator protection.

A vacuum circuit breaker is a vital component of modern electrical systems. Their ability to extinguish the electric arc quickly, their reliability, and their environmental benefits make them a preferred choice for many applications. From industrial facilities and substations to commercial buildings, VCBs provide unmatched protection for electrical equipment and infrastructure. As the industry continues to evolve with the integration of smart grid technology and a focus on sustainability, VCBs are poised to play an even greater role in the future of power distribution and control systems.

If you’re looking for technical training or planning support, explore our electrical substation training programs or consult with our substation maintenance training team.

Related Articles