Why Electrical Frequency Supply is 50 Hz or 60 Hz?

By G. Fox, Editor, Electricity Forum

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Electrical frequency supply ensures 50/60 Hz AC power, grid stability, frequency regulation, power quality, and synchronized operation across generation, transmission, and distribution networks, supporting loads, inverters, and synchronous machines reliably.

Why Electrical Frequency Supply Matters in Power Distribution

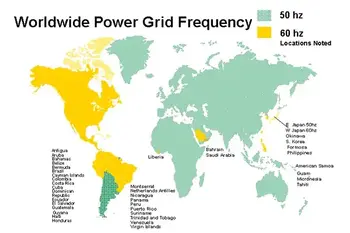

Many many years ago we did not have integrated power system as we have now. There were multiple standards and load items which weresuitable for their power system. Operating electrical frequency ranges were between 16.75 Hz to 133.33 Hz.

When people think about large power generation system, they puzzled with the standard that to be adopted by them. Finally it reveals about single standard for all. They came to conclusion regarding to their issue, from the analysis and performance evaluation conducted on different standards of power system by them. In parallel, understanding how electrical substations function shapes decisions about frequency standards.

Then they felt single standard is essential! because production of electric devices were limited by realm of power system boundary i.e., suppose a country consist of 10 different standards then 10 different manufacturing measures and processes are required for same device. This factor puts hurdles in batch production of device. It leads electric devices much more costly. In practice, standardization also simplifies electrical substation design across regions and manufacturers.

There is no strong technical reason behind 50 Hz or 60 Hz. This is not like that these values give best performance among all other available standard values of supply frequencies. But these two electrical frequencies give good optimized performance among others. Since superior performance has been found finally these values 50 Hz and 60 Hz were picked by most of the electrical power systems. Today, advanced controls in digital substations further support reliable operation at these frequencies.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Technical Reasons for not using Higher Frequencies

- It increases series impedance in electrical transmission system. This reduces power transfer capability so we cannot access full fruit of transmission system.

- Constant losses are directly proportional to frequency and its square, so they may increase system losses.

- Harmonics with higher frequency can carry more power and it introduces excess heat losses.

- As the frequency directly proportional to the rotating speed of alternator and it is not practical to construct very high speed gigantic alternators. Hence it is practically difficult to achieve high frequency electrical power during generation.

Problems with Lower Frequencies

In past days they observed some issues with electrical frequencies which are less than 40 Hz.

- Perceptible flickering in filament lamp, starting problem in arc lamp and arcing devices so they need additional devices for starting purpose and for maintaining better operation.

- Electrical Frequency is directly proportional to power hence size of lower frequency devices are quite larger than higher frequency so material involved, cost involved in manufacturing and transporting are also quite larger than that of higher frequency devices.

These are the reasons in aircraft, in ships and in similar type isolated loads, higher frequencies are used.

From these relations we can conclude without confusion, larger frequency reduces area of core in transformer and magnetic circuits. Devices which have bigger magnetic circuit weight more. It is needless to say weight of net system is in great concern in ship and aircraft. So there we have higher frequency devices.

These considerations influence the selection of electrical substation components that must tolerate expected impedance, losses, and thermal stresses.

Accordingly, protection philosophies in substation protection account for flicker, inrush, and stability concerns at lower frequencies.

Regardless of the chosen frequency, robust substation grounding ensures fault currents are safely dissipated and step-and-touch potentials remain within limits.

From these relations we can conclude without confusion, larger frequency reduces area of core in transformer and magnetic circuits. Devices which have bigger magnetic circuit weight more. It is needless to say weight of net system is in great concern in ship and aircraft. So there we have higher frequency devices. For high-voltage measurement and relaying, capacitor voltage transformers in substations provide accurate scaling and insulation performance across the adopted frequency range.