Fault Indicator Explained

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

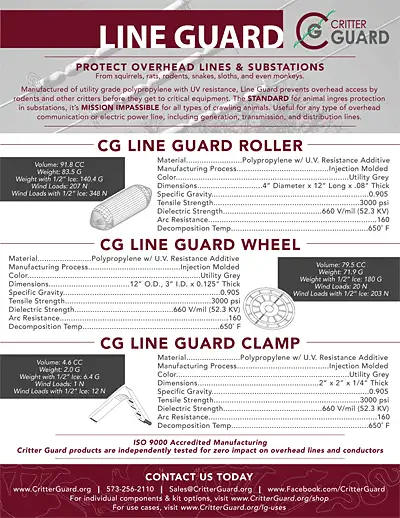

A fault indicator is an electrical device that detects and displays fault conditions in power systems. Used in distribution networks and switchgear, it improves fault detection, outage response, and grid reliability while supporting predictive maintenance.

What is a fault indicator?

A fault indicator is a monitoring device used in electrical distribution systems to quickly locate fault conditions and improve service reliability.

✅ Detects and displays fault conditions in power lines

✅ Enhances outage response and reduces downtime

✅ Supports predictive maintenance and grid efficiency

Understanding how this device functions and its role in maintaining a reliable power system is crucial for any electrician working in an industrial setting. Let’s explore the core concepts, their various applications, and the benefits they offer in terms of issue location, outage reduction, and overall system reliability. By reading this article, an industrial electrician will gain valuable insights into how a fault indicator contributes to safer, more efficient, and more resilient electrical infrastructure. Fault indicators play a crucial role in distribution automation, where remote monitoring and SCADA integration are essential for enhancing grid resilience.

They play a critical role in modern power systems by providing a rapid and reliable means of detecting and locating disturbances. These devices are essential for minimizing downtime, improving safety, and ensuring the efficient operation of electrical networks. In modern electrical distribution systems, fault indicators provide real-time fault location that speeds up troubleshooting and repair.

A faulted circuit indicator (FCI) is more than a simple signal device; it functions as a reliable circuit monitoring device that helps utilities quickly identify abnormal conditions. Whether used as an overhead line indicator on distribution networks or integrated into underground systems, these tools improve outage response and reduce downtime. When connected to SCADA fault detection platforms, they provide real-time data that supports proactive maintenance and rapid dispatch of crews. As utilities transition toward smart grid monitoring, advanced FCIs play a key role in creating safer, more resilient, and efficient power systems.

Sign Up for Electricity Forum’s Overhead T&D Newsletter

Stay informed with our FREE Overhead T&D Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Fault Location/Detection

A primary function of these devices is to pinpoint the exact location of a circuit problem. This capability is crucial in complex networks with extensive overhead lines and underground cables. Overhead indicators are strategically placed along power lines to visually signal the presence of an issue. When a disturbance occurs, the indicator activates, providing a clear cue to line crews that enables them to quickly identify the affected section and commence repairs. Underground indicators are installed in cable systems and vaults to detect conditions beneath the surface. This precise location capability reduces the time and effort required to identify and address problems, resulting in faster restoration of service. Utilities that depend on reliable electric power distribution benefit from fault indicators to quickly identify and isolate problem areas.

Technology/Functionality

Modern FCIs sense both magnetic and electric fields to distinguish between normal load surges and true electrical events, enabling directional detection and avoiding false trips. With detection speeds measured in milliseconds, they provide real-time pinpointing. Current sensing remains a common approach, but advanced models also utilize digital signal processing (DSP) to minimize false alarms. Some units feature inrush restraint to prevent tripping during temporary surges. Remote indication capability enables the wireless transmission of data to SCADA systems or control centers, providing operators with immediate insight and facilitating the faster dispatch of crews.

Standards & Features

Leading designs include variable trip thresholds, multiple reset types, and low-pass filtering to minimize misoperations. Many models are hotstick-installable for safety and conform to IEEE compliance standards, ensuring reliability across diverse applications. These features not only enhance accuracy but also reduce maintenance requirements, enabling efficient long-term operation.

Historical Evolution

Since their introduction in the 1940s, these devices have evolved from simple manually reset flags to sophisticated electronic equipment. Early versions required crews to manually reset them after repairs. Over time, automatic reset functionality, LED indicators, and remote communication were added. Today’s smart indicators integrate programmable logic, data logging, and seamless communication with grid monitoring systems, reflecting decades of advancement in line sensor evolution. As electricity transmission networks expand, indicators become increasingly critical in maintaining safety and reducing large-scale outages.

Benefits

The benefits of using these monitors are numerous and far-reaching. By quickly identifying the affected circuit, they significantly reduce outage time, minimizing disruption to customers and businesses. This rapid location capability also enhances the overall reliability of the power system, as it enables faster repairs and restoration of service. They improve safety by enabling quick isolation of the affected section, preventing escalation and hazards to personnel. In wildfire-prone areas, indicators support rapid response strategies that reduce risks associated with downed lines and delayed detection.

Smart Grid Integration

Today’s FCIs are part of broader smart grid monitoring strategies. Integrated with SCADA systems, they provide operators with real-time situational awareness. Some advanced designs incorporate wireless transmitters and receivers that signal directly to protective relays, allowing for rapid and coordinated isolation. This integration improves grid resilience, reduces downtime, and supports predictive maintenance by identifying intermittent or developing issues before they escalate. With the rise of smart grid technologies, fault indicators are evolving into intelligent sensors that enhance monitoring and predictive maintenance.

Comparison of Indicator Types

| Type | Features | Typical Application |

|---|---|---|

| Basic Visual | Manual reset, flag or LED indication | Overhead distribution lines |

| Automatic Reset | Resets after fault clears, simple indication | Overhead and underground |

| Electronic | Current/voltage sensing, inrush restraint, low-pass filtering | Substations, industrial systems |

| Smart/SCADA Integrated | DSP filtering, wireless communication, remote reset, programmable logic | Utilities, smart grid monitoring |

Analysis

The strong emphasis on line location highlights its critical importance in power system management. Accurately pinpointing the source of a disturbance is paramount for efficient troubleshooting and timely restoration. The increasing adoption of real-time monitoring, inrush restraint, and remote indication demonstrates a trend toward more sophisticated management systems. This technological diversity enables greater flexibility and customization, meeting the specific needs of utilities, industrial facilities, and smart grid operators. In overhead T&D, fault indicators complement devices like the electrical insulator by improving protection against system faults.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Frequently Asked Questions

What is a fault indicator, and how does it work?

It’s a device that detects and signals the presence of an abnormal condition in an electrical power system. It works by monitoring parameters such as current and voltage, triggering an alert when unusual activity is detected. This alert may be visual (flag or LED) or transmitted remotely to a control center.

What are the different types available?

They are categorized based on their application and functionality. Common types include:

-

Overhead: Used on overhead lines, typically visual.

-

Underground: Designed for cable vaults, often audible or remote.

-

Electronic: Offer advanced features like DSP filtering, inrush restraint, and communication.

-

Smart/SCADA: Fully integrated into monitoring and relay systems.

How do fault indicators improve power system reliability?

They reduce outage times, support immediate response through remote signaling, and enhance preventive maintenance by identifying intermittent problems before escalation.

What factors should be considered when selecting?

Consider factors such as application (overhead or underground), environmental conditions, functionality (visual vs. remote), accuracy, standards compliance, and installation requirements.

How are they installed and maintained?

Overhead indicators are typically pole-mounted, while underground versions are installed in vaults or directly on cables. Maintenance involves inspections, testing, and cleaning. Electronic units may require battery changes or firmware updates.

Do they ever give false alarms?

Advanced models use DSP filtering, inrush restraint, and directional detection to minimize false indications. Proper placement and settings further improve accuracy.

A fault indicator is an indispensable tool for maintaining the reliability and safety of modern power systems. From their origins in simple visual devices to today’s smart, SCADA-integrated models, their ability to quickly and accurately locate circuit issues significantly reduces outage times and improves overall grid resilience. By understanding their functions, standards, and benefits, electricians and system operators can make informed decisions that strengthen electrical infrastructure and support the transition to smarter, safer, and more efficient networks.