The Role of AI and Machine Learning in Predicting Transformer Faults

By R. W. Hurst, Editor

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

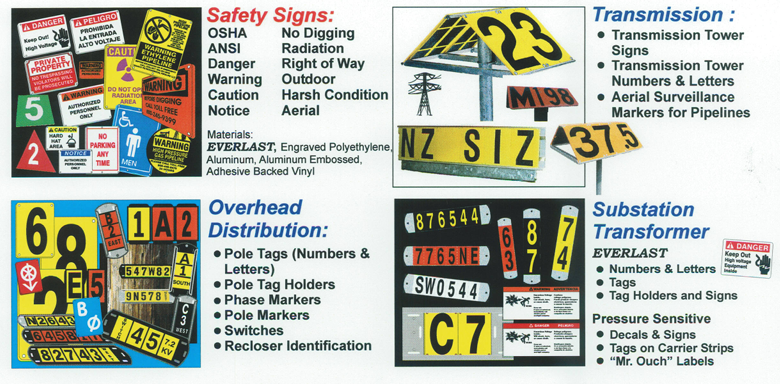

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

AI and Machine Learning can predict transformer faults by analyzing dissolved gas data, thermal patterns, and vibration trends to identify insulation degradation, detect anomalies, and prevent costly power transformer failures before they occur.

Why AI Integration into Transformer Diagnostics Matters

-

Applies machine learning to transformer data for predictive fault detection.

-

Analyzes DGA, temperature, and vibration trends for early anomaly alerts.

-

Enhances reliability through automated, data-driven maintenance decisions.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The Shift Toward Predictive Intelligence

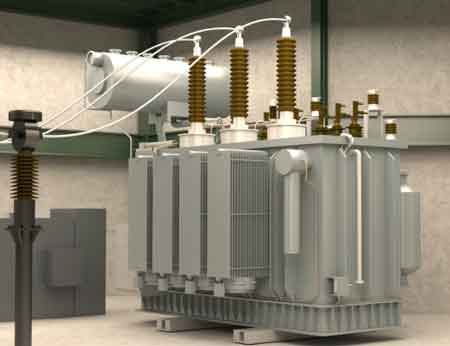

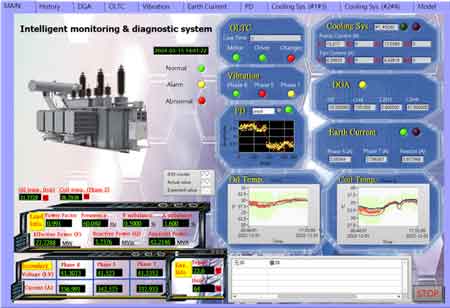

Artificial intelligence (AI) and machine learning (ML) are revolutionizing transformer diagnostics by transforming raw monitoring data into predictive insights. For decades, transformer condition assessment depended on manual interpretation of dissolved gas analysis (DGA), partial discharge readings, thermographic surveys, and insulation testing. These techniques remain vital, but they rely on human experience and periodic testing. Modern transformers, however, operate in environments generating massive volumes of continuous data from sensors and online monitoring systems—far more than any engineer can interpret unaided. Modern utility transformers are increasingly relying on AI and IoT connectivity to enhance condition monitoring, optimize performance, and extend service life across critical power networks.

AI changes that dynamic. Machine learning algorithms can process years of historical and real-time data in seconds, identify nonlinear trends invisible to the naked eye, and correlate patterns across multiple data sources. Instead of spotting faults after they occur, AI recognizes the subtle signatures of deterioration long before failure. This represents a fundamental shift from reactive maintenance toward proactive asset management, where every transformer becomes a continuously monitored, self-learning system. When applied to power transformers, AI algorithms analyze temperature, oil quality, and loading trends to detect emerging insulation or winding issues before they cause costly failures.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

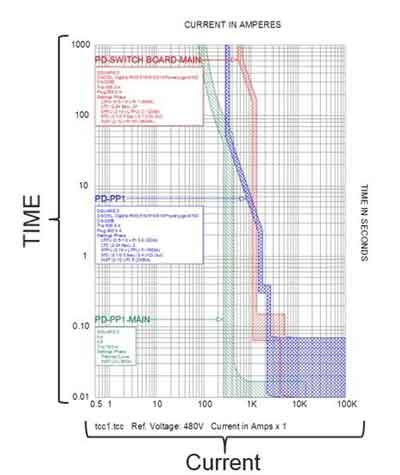

Predictive intelligence allows utilities and industrial facilities to manage risk more precisely. Rather than relying on calendar-based inspections or fixed testing intervals, maintenance can be triggered only when the data indicates genuine concern. For example, an AI model might detect a slow but consistent increase in ethylene or acetylene within a DGA profile, suggesting localized thermal stress in the insulation material. Engineers can then schedule an inspection or oil sample test before a breakdown occurs, preventing costly downtime. This shift toward condition-based maintenance extends equipment life and optimizes operating budgets.

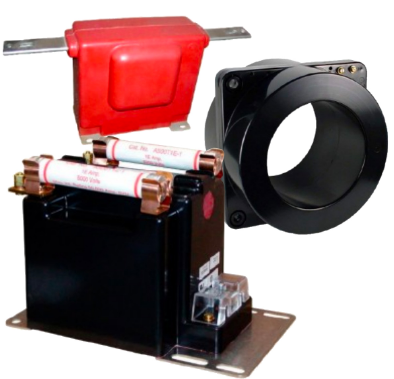

How AI Detects Anomalies and Integrates Complex Data

Anomaly detection is one of AI’s most powerful diagnostic tools. Machine learning models—especially unsupervised types such as clustering or autoencoders—learn what “normal” looks like for each transformer. They analyze data streams such as temperature, vibration, load current, moisture, and gas composition to establish a baseline pattern. When operating behaviour deviates from this baseline, the system flags an anomaly. Predictive models are particularly valuable in distribution transformers, where fault detection and remote diagnostics help utilities reduce unplanned outages and enhance grid reliability.

For instance, an autoencoder might recognize that a transformer typically exhibits a stable relationship between winding temperature and load. If the temperature begins to climb more sharply than expected at a given current, the algorithm registers an abnormal pattern—an early warning of cooling inefficiency or insulation deterioration. Unlike traditional threshold methods, which depend on preset numerical limits, AI adapts to each unit’s unique operating signature, making detection more precise and context-sensitive.

Data integration is another key advancement. Historically, transformer test results, such as DGA, power factor, bushing capacitance, partial discharge, oil moisture, and thermal images, were stored and analyzed separately. AI systems now merge these diverse datasets into a unified health index. They correlate variables across domains—for example, connecting moisture ingress in oil with partial discharge spikes, or linking tap-changer activity to rising gas levels. By integrating mechanical, thermal, and electrical parameters, AI creates a comprehensive picture of transformer condition, thereby reducing diagnostic uncertainty.

Digital twins extend this integration into the predictive domain. A digital twin is a virtual model of a transformer that mirrors its physical counterpart in real time. It continuously receives live data from sensors, compares actual performance to expected behavior, and predicts how aging, loading, or environmental conditions will influence future operation. Engineers can run “what-if” simulations—such as overloads, ambient temperature extremes, or cooling system failures—to evaluate risk without exposing equipment to stress. This capability transforms maintenance planning from reactive troubleshooting into predictive forecasting. AI integration supports continuous condition monitoring in an age of modernization, allowing operators to correlate DGA results, vibration data, and real-time thermal profiles for accurate risk assessment.

Benefits, Applications, and Emerging Best Practices

The adoption of AI-based diagnostic tools delivers measurable benefits across the power industry:

-

Improved diagnostic accuracy through real-time, data-driven pattern recognition.

-

Earlier fault detection enables condition-based interventions rather than emergency repairs.

-

Reduced downtime and fewer catastrophic failures.

-

Integration with SCADA and IoT platforms for continuous visibility across the grid.

-

Optimized maintenance budgets through prioritization of high-risk assets.

-

Knowledge retention as AI captures and replicates decades of expert analytical experience.

Utilities are already applying these methods in pilot programs and live operations. Some have trained neural networks to automatically interpret DGA results, identifying fault types such as overheating, partial discharge, or arcing with accuracy comparable to that of seasoned engineers. Others use reinforcement learning to optimize transformer loading, balancing efficiency with longevity. Predictive analytics have successfully identified winding failures, core defects, and oil degradation months in advance, allowing for planned outages instead of costly unplanned ones. In high-demand environments, high-voltage transformers benefit from machine learning systems that interpret load variation patterns and prevent overstressing under peak operation.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

In industrial settings, AI assists maintenance teams by consolidating data from numerous transformers into dashboards that highlight risk levels and maintenance priorities. When an anomaly appears, the system generates an automated report describing probable causes, severity ranking, and recommended next steps. This not only shortens response times but also standardizes decision-making across facilities.

Students and maintenance professionals learning about these systems should also consider the supporting infrastructure required for success. AI depends on high-quality, standardized data. Without consistent calibration, sensor accuracy, and proper data labelling, even sophisticated algorithms can produce misleading results. Following international standards such as IEC 61850 for data communication and IEEE C57 for transformer testing and monitoring ensures compatibility and reliability.

Cybersecurity is another vital consideration. As transformers become part of connected, data-driven networks, they are increasingly exposed to potential cyber threats. Protecting AI-enabled monitoring systems with robust encryption, access control, and secure communication protocols is crucial to maintaining operational integrity.

The Human-AI Partnership

Despite its analytical power, AI does not eliminate the need for skilled human expertise—it amplifies it. Engineers must interpret AI output, validate model conclusions, and apply contextual judgment. AI can recognize patterns, but it cannot yet account for all the operational realities, such as weather, system load fluctuations, or unique design differences, that influence transformer performance. Human oversight remains indispensable for verifying whether an anomaly is genuinely dangerous or a benign variation. Combined with innovations in transformer design and digital twin technology, AI allows engineers to simulate performance degradation and test maintenance scenarios without physical intervention.

Successful implementation, therefore, requires a hybrid model: AI provides speed, scale, and pattern recognition; humans provide understanding, context, and accountability. Training programs should emphasize this collaboration, helping professionals learn how to interpret AI reports, adjust algorithm parameters, and integrate predictive insights into day-to-day maintenance planning.

AI also promotes knowledge continuity in a workforce facing retirements and skill shortages. Machine learning systems retain diagnostic intelligence that might otherwise be lost when experienced engineers leave. In this way, AI becomes both a tool and a repository of institutional expertise—one that evolves as more data is gathered and analyzed.

Looking Ahead

The future of transformer maintenance lies in intelligent integration. AI will increasingly combine with Internet of Things (IoT) devices, digital twins, and cloud-based analytics to form self-learning ecosystems that continuously assess transformer health. As computing power grows and models mature, predictive accuracy will approach real-time reliability. The future of transformer diagnostics will rely on advanced analytics integrated into electrical substation transformers, ensuring real-time decision support and safer, more efficient grid operations.

Still, the objective is not to replace traditional testing but to enhance it. Routine tests, visual inspections, and manual diagnostics remain essential for confirming AI findings and ensuring compliance with safety standards. When technology and expertise work together, transformer management becomes not only more efficient but also more insightful.

AI integration represents a turning point in electrical asset management—a movement from hindsight to foresight, from reactive maintenance to predictive intelligence. By embracing these tools, the next generation of power engineers can ensure that transformers, the backbone of the electrical grid, operate more safely, reliably, and economically than ever before.

Related Articles