How Many Volts Go Into a Distributor Bucket Transformer

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

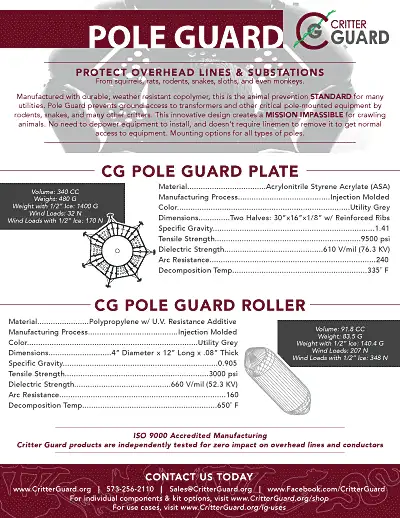

How many volts go into a distributor bucket transformer? Typically, a pole-mounted distribution transformer takes 7.2-13.8 kV primary and steps down to 120/240 V service; values vary by utility feeder, region, and system design.

How Many Volts Go Into a Distributor Bucket Transformer?

Typically 7.2-13.8 kV primary, stepped down to 120/240 V; exact values depend on utility standards.

✅ Common primary: 7.2, 7.62, 12.47, 13.2, 13.8 kV (utility-dependent)

✅ Typical secondary: 120/240 V split-phase for residential service

✅ Verify nameplate for primary kV, kVA, phase, and tap settings

How many volts go into a distributor bucket transformer? is a critical question for electrical engineering and maintenance professionals. Understanding the primary voltage levels applied to these transformers is essential for several reasons. Firstly, it ensures the safe and efficient operation of the electrical grid, minimizing the risk of equipment failure and power outages. Secondly, it allows for proper selection and sizing, ensuring that the equipment can handle the expected loads. Finally, knowledge of primary voltages is crucial for adhering to electrical safety codes and regulations, protecting both workers and the public from potential hazards.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The voltage that goes into a distributor bucket transformer plays a crucial role in determining its performance, safety, and efficiency. Understanding the electrical specifications and operational requirements of these units is essential for electrical engineers, contractors, and utility workers. Distributor bucket transformers are a vital part of electrical distribution systems, especially when stepping down high-voltage electricity to levels suitable for residential, commercial, and industrial applications. These units are a subset of distribution transformers commonly deployed on feeders and service drops.

Typical Primary Voltages

Typically, distributor bucket transformers receive a primary voltage ranging from 7,200V to 13,800V, depending on the specific design of the local grid infrastructure. This primary voltage is crucial for ensuring the effective distribution of electricity. The primary and secondary windings within these they facilitate the process of voltage conversion. Primary voltage is introduced through the primary windings, while secondary voltage is produced through the secondary windings to provide usable electricity for end-users. The supply voltage must align with local utility standards to ensure proper operation and safety. In protection and metering, the term voltage transformer often denotes instrument-class PTs used to step down signals safely for relays and meters.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Distributor bucket transformers are categorized into single-phase transformer and three-phase transformer. Single-phase transformers are commonly used in residential areas, while three-phase ones support larger commercial and industrial applications. These phase units are specifically designed to meet the energy demands of their respective loads. The phase system, whether single or three-phase, affects the efficiency and power output. The way they connect to the electrical grid depends on the type of phase system in use. Open delta configurations are sometimes used as a cost-saving measure for certain three-phase systems. These configurations offer a balance between operational efficiency and cost, especially in areas with fluctuating power demands.

Safety precautions are paramount when working with distributor bucket transformers, as the high voltages involved pose significant hazards. Workers must follow strict lockout/tagout procedures, ensure proper grounding, and wear personal protective equipment (PPE) to prevent accidental contact with live electrical components. Electrical safety standards, such as those set by the National Electrical Code (NEC), dictate how they are designed and operated to minimize risks. Compliance with these codes is essential for the safe installation, maintenance, and operation of distribution systems.

Transformer Types

Different types are used in power distribution systems, including isolation, dry type transformers, and auto transformer. Isolation ones provide electrical isolation between the primary and secondary windings, reducing the risk of shock and ensuring greater safety. Dry-type, on the other hand, use air rather than liquid for cooling, making them suitable for indoor environments where fire hazards must be minimized. Autotransformers differ from other designs by using a single winding to serve both primary and secondary functions, offering a more compact and cost-effective solution for voltage conversion. Each type serves specific purposes, depending on the application's voltage requirements and environmental conditions. For bulk transfer between transmission and subtransmission levels, utilities rely on power transformers that operate at higher MVA ratings than bucket-style units.

The load capacity of a distributor bucket transformer is another key factor influencing the required voltage. They are designed to handle a full load of electricity without overheating or experiencing voltage drops. The load that the unit must support is calculated using kilovolt-ampere (kVA) ratings, which represent the maximum amount of power it can safely handle. kVA ratings dictate the capacity to serve residential and commercial loads effectively. When operating at full load, these transformers must maintain maximum efficiency to minimize energy losses and ensure consistent power delivery. If the load exceeds the capacity, the voltage output may drop, leading to potential service interruptions or equipment damage. Selecting the correct kVA aligns the unit with the broader electrical power distribution transformer architecture of the circuit for reliability.

Another essential consideration is the role of buck-boost transformers in power systems. Buck-boost transformers are commonly used to make minor adjustments to the supply voltage. When supply voltage is slightly higher or lower than required, a buck-boost transformer can increase (boost) or decrease (buck) the voltage to the desired level. These transformers are often used to correct slight deviations in supply voltage, ensuring that downstream equipment receives a stable and reliable power supply. This type of adjustment prevents under-voltage or over-voltage conditions, protecting electrical devices from damage.

Electrical Codes and Standards

Electrical codes and standards, such as those set by the NEC, play a significant role in how distributor bucket transformers are specified and installed. Compliance ensures the safe and effective operation of the electrical distribution system. These standards address the acceptable range of primary voltage, the grounding, and how they connect to distribution systems. Adhering to these guidelines ensures they operate safely and efficiently while minimizing risks to personnel and equipment.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Applications

The applications of distributor bucket transformers are widespread, supporting residential, commercial, and industrial power needs. These step down high-voltage distribution lines to lower voltages suitable for powering homes, businesses, and industrial facilities. This process enables the safe delivery of 120 volts and other usable voltages to homes and buildings. By converting the high primary voltage to a lower secondary voltage, distribution units provide the essential electrical energy required for lighting, appliances, and industrial machinery. These transformers must be designed to accommodate the specific voltage needs of the area they serve, ensuring stable and consistent power delivery. In overhead systems, many bucket configurations are implemented as pole-mounted transformers to reach dispersed loads efficiently.

Frequently Asked Questions

What is the input voltage of a distribution transformer?

The input voltage typically ranges from 2.4 kV to 34.5 kV, depending on the system's design and the utility's distribution network. This high voltage allows for efficient transmission of electrical energy over long distances with minimal power loss. The input voltage is referred to as the "primary voltage". Upstream on the grid, high-voltage transformers handle transmission-level steps before energy reaches distribution circuits.

How many volts come into a transformer?

The voltage that comes into a transformer varies depending on its application. For distribution types, the incoming voltage is usually between 2.4 kV and 34.5 kV. For smaller residential transformers, the voltage may be 7.2 kV, 13.8 kV, or 25 kV. Industrial types can have even higher incoming voltages, especially for large facilities connected directly to high-voltage transmission lines.

What voltage do pole-mounted transformers step down to?

Pole-mounted transformers step down high distribution voltages (typically 7.2 kV, 13.8 kV, or 25 kV) to lower, usable secondary voltages for residential and commercial use. The most common secondary voltages are 120/240 V for residential applications. This allows homes and small businesses to safely power electrical devices and appliances. These devices are often referred to as an electric pole transformer in utility vernacular, especially in residential neighborhoods.

What is the standard voltage of a transformer?

The standard voltage depends on its application. For residential types, the output (secondary) voltage is typically 120/240 V in North America. For commercial and industrial ones, the standard output voltage can be 208 V, 480 V, or 600 V, depending on the system's needs. On the primary side, the standard voltages are commonly 2.4 kV, 7.2 kV, 13.8 kV, 25 kV, or 34.5 kV for distribution networks.

The voltage that goes into a distributor bucket transformer typically ranges from 7,200V to 13,800V. The primary and secondary voltages are managed through windings, which is influenced by the type, load capacity, and phase system. Compliance with electrical codes and adherence to safety precautions are essential to ensure safe and efficient operation. Various transformer types, including autotransformers, isolation transformers, and buck-boost transformers, play key roles in meeting the diverse voltage demands of modern power distribution systems. With proper design, maintenance, and safety protocols, distributor bucket transformers continue to serve as a vital component in electrical power distribution.