Arc Flash Blast Explosion – NFPA 70E Pressure and Overpressure

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

An arc flash blast explosion releases intense heat and pressure within milliseconds, hurling molten metal and gas with deadly force. NFPA 70E safety training and proper PPE are essential to prevent severe burns, equipment damage, and hearing injuries.

What is an Arc Flash Blast Explosion?

An arc flash blast explosion occurs when an electrical fault ionizes the air, creating a plasma arc that releases tremendous energy. The event combines extreme heat, overpressure, and high-decibel noise.

✅ Temperatures can exceed 35,000°F, instantly vaporizing copper conductors

✅ Expanding gases create an explosive pressure wave that can throw a worker several feet

✅ Molten metal and shrapnel are ejected at high velocity, requiring full protective barriers

Unlike a simple short circuit, an arc blast releases both thermal and mechanical energy. The rapid rise in pressure—sometimes hundreds of pounds per square inch—can rupture switchgear doors and ignite fires in surrounding equipment. For a broader discussion of electrical explosion hazards, see our Electrical Explosion page.

Request a Free Training Quotation

An arc flash occurs when an electrical current unexpectedly jumps a gap, creating a connection through air to ground or another voltage phase in an electrical system. This type of electrical explosion produces an intense electrical arc that releases massive energy in a fraction of a second. The energy released during an incident can reach temperatures hotter than the surface of the sun, instantly vaporizing conductors and launching molten metal outward. Such extreme conditions are life-threatening, capable of causing severe burns, hearing loss, and equipment destruction.

The common causes include equipment failure, loose connections, contaminated insulation, and improper work practices near energized systems. When an explosion reaches these critical fault conditions, the resulting flash and arc blast generate both thermal and mechanical energy, endangering anyone nearby. Proper hazard assessment and the use of personal protective equipment (PPE)—such as flame-resistant clothing, insulated gloves, and face shields—are essential to survive these events. Adhering to NFPA 70E and CSA Z462 standards helps workers understand how incidents occur, why they are so dangerous, and how to minimize risk through preventive maintenance and safe operating procedures.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The Physics of an Arc Blast

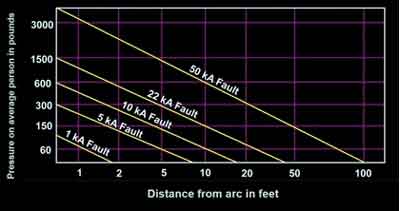

When an arc fault occurs, superheated gases expand violently, forming a pressure wave that radiates outward from the fault. In confined spaces, this blast wave can rebound off walls, amplifying its destructive force.

-

Pressure expansion: Even a small arc fault can generate overpressures of several hundred PSI within inches of the fault, capable of deforming metal panels and dislodging heavy components.

-

Sound levels: Noise intensity may exceed 160 decibels—comparable to a gunshot at close range—enough to rupture eardrums and cause permanent hearing loss.

-

Equipment enclosure dynamics: In enclosed switchgear, trapped gases can blow open doors or seams, turning panel fragments into projectiles. Venting systems and arc-resistant enclosures are designed to channel this force safely away from personnel.

A 480-volt arc generating 20 kA can create an initial pressure spike exceeding 700 PSI within 30 cm of the fault.

Arc Flash Blast Explosion Pressure Wave Radius

Reducing the Risk of Explosions

Arc flash blast explosions can be prevented through disciplined engineering and maintenance practices, including:

-

Performing detailed risk assessments

-

Installing current-limiting fuses and arc-resistant switchgear

-

Maintaining clean, tight electrical connections

-

Using infrared and ultrasonic inspections to detect faults early

For details on safe working distances and approach limits, see our Arc Flash Boundary Guide. Personnel should follow lockout/tagout procedures and remain outside the calculated boundaries unless they are fully qualified and properly protected.

The Role of PPE

Arc-rated PPE provides the final layer of defence when engineering controls cannot eliminate exposure. Flame-resistant clothing, hoods, gloves, and hearing protection are selected based on calculated incident energy (cal/cm²). In high-risk areas, a 40-calorie Arc Flash Suit offers maximum protection against extreme conditions.

PPE must be inspected before use, correctly fitted, and worn with discipline. Combining PPE with proper equipment labeling and energized work permits forms a complete safety system.

Major Hazards and Consequences

Arc flash blast explosions produce multiple compounding effects:

-

Thermal Energy: Causes third-degree burns and ignites flammable materials.

-

Pressure Waves: Create blunt-force trauma and structural damage.

-

Sound Energy: Exceeds 140–165 dB, which can damage hearing instantly.

-

Molten Metal and Fumes: Cause eye, respiratory, and skin injuries.

By integrating NFPA 70E principles, conducting regular assessments, and maintaining protective devices, organizations can drastically reduce these risks and ensure safer working environments.

Frequently Asked Questions

What Causes an Arc Flash Blast Explosion?

An arc flash blast occurs when electricity jumps through the air between conductors, producing plasma and rapid gas expansion. Common causes include equipment failure, poor maintenance, dropped tools, or accidental contact with live parts. Learn more about fault energy in our Electrical Explosion guide.

What Are the Main Hazards of an Blast?

The event releases extreme heat, overpressure, and noise. Workers face third-degree burns, hearing loss from pressure waves over 140 dB, and eye or respiratory injuries from molten metal and fumes. Proper NFPA 70E Training teaches how to recognize and control these hazards.

What Determines the Severity of an Arc Blast?

The magnitude of available fault current, system voltage, and proximity to the fault are the main factors of severity. Poorly maintained equipment and missing protective devices greatly increase the risk. See our Arc Flash Analysis Guide for prevention methods.

What Are the Approach Boundaries for Protection?

NFPA 70E defines three safe-distance zones:

-

Limited Approach Boundary – minimum distance for unqualified personnel.

-

Restricted Approach Boundary – allows only trained workers using PPE.

-

Arc Flash Boundary – zone where a person could receive a second-degree burn.

Learn more in our Arc Flash Boundary Guide.

Related Articles