High-Voltage Electrician

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

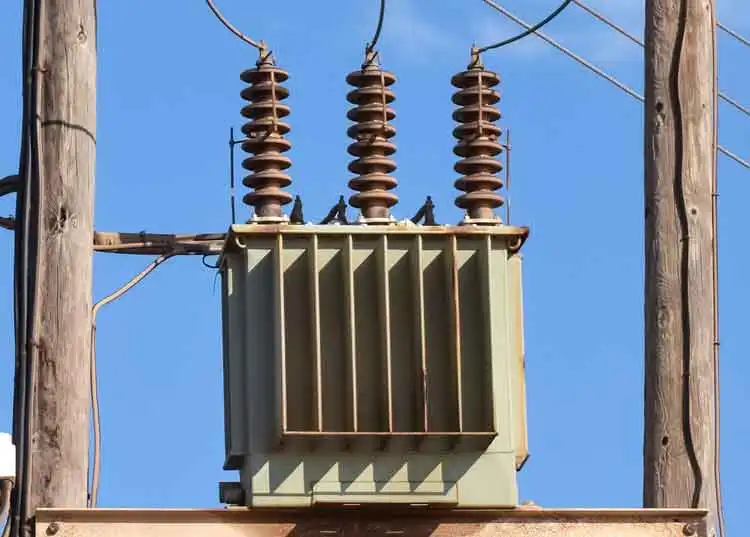

A High Voltage Electrician installs, maintains, and repairs medium and high-voltage power lines, substations, and electrical systems above 1 kV, ensuring grid reliability, safety, and compliance with utility and industry standards.

What is a High Voltage Electrician?

A High Voltage Electrician is a skilled tradesperson who works with electrical power systems above 1,000 volts, ensuring safe installation, maintenance, and operation.

✅ Installs and maintains high voltage electrical systems in industrial and utility settings

✅ Troubleshoots electrical faults in industrial and utility systems

✅ Ensures compliance with OSHA, NFPA, and utility safety standards

Request a Free Training Quotation

High-voltage electricians are highly skilled professionals who work with extremely dangerous electrical power to ensure the safe operation of electrical systems. They are responsible for the installation, maintenance, and repair of high-voltage equipment, such as power lines, transformers, and switchgear. Understanding the responsibilities and risks associated with working on electrical power systems is vital for industrial electricians, as these systems require specialized knowledge and skills. This article will examine the key aspects of electrical power technician work, including the training and experience required, safety protocols, and the challenges encountered in the field. Electricians will gain valuable insights into maintaining, repairing, and troubleshooting electrical power systems, ultimately enhancing their expertise and ensuring optimal safety and performance in their electrical work. OSHA’s guidelines for hazard control are directly linked to 29 CFR 1910.147, which outlines lockout/tagout requirements for hazardous energy control.

Responsibilities of a High Voltage Electrician

A high voltage electrician is tasked with a wide range of responsibilities, primarily focused on ensuring the proper functioning of electrical distribution systems. These systems carry electricity from power plants to substations and from substations to end-users, such as consumers. The electrician's role includes installing, maintaining, and repairing high-voltage electrical systems, which involves working with power lines, transformers, and electrical power regulators. They also perform underground cable splicing, install conduit and ductwork, and erect utility poles as needed for new installations or system upgrades.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

In addition to hands-on work, experienced high voltage electricians often supervise other electricians or apprentices, ensuring that all work meets established safety protocols and quality standards. They are responsible for enforcing compliance with applicable codes and procedures while mentoring less experienced personnel. Troubleshooting and repair work include using specialized testing equipment to identify faults in circuits, address power distribution problems, and keep systems operating safely and efficiently. To align with OSHA enforcement on control methods, check out our article on Is Arc Flash Analysis Required by OSHA.

The Importance of Experience and Training

The role of a high voltage electrician requires extensive training and experience. The systems they work with operate at electrical power levels that can cause severe injury or even death if not handled properly. To become qualified, candidates must undergo rigorous training at trade schools and complete apprenticeships, where they learn the necessary skills for handling electrical power equipment.

In most cases, journey-level certification is required, along with a strong working knowledge of the National Electrical Code (NEC), IEEE safety standards, and other applicable regulations. Employers typically seek candidates with multi-year experience in utility or industrial environments, where exposure to high-voltage systems is common. This hands-on experience, often gained under the supervision of senior electricians, is essential for developing the technical competence and safety awareness needed for the job.

Once trained, high voltage electricians must stay up to date with evolving technologies, system upgrades, and changing safety protocols. Ongoing education and certification ensure they remain capable of addressing the complex and high-risk challenges that come with maintaining large-scale electrical infrastructure.

Safety Protocols and Compliance with Regulations

Safety is the top priority for electrical power technicians due to the inherent risks of working with electrical power. These electricians must adhere to strict safety standards and regulations designed to protect them and others from electrical hazards. In North America, compliance with NFPA 70E (U.S.) and CSA Z462 or CAN/ULC S801 (Canada) is essential. These standards provide detailed guidance on safe work practices for electrical operations, including requirements for risk assessments, arc flash hazard analysis, and personal protective equipment (PPE).

Establishing clearly defined safe work zones is a critical component of high voltage electrical safety. Electricians must understand and maintain boundaries for limited, restricted, and arc flash zones—each specifying proximity limits based on voltage and incident energy levels. These zones are enforced to reduce the risk of electric shock and arc flash exposure. In many scenarios, a standby observer (also known as a safety watch) must be present, trained in emergency response procedures and ready to assist or perform a rescue if an incident occurs.

Additionally, a high voltage electrician often engages in live-line maintenance, where work is performed on energized equipment to minimize system downtime. This requires the use of specialized tools and techniques, including hot sticks (insulated poles used to manipulate energized components from a distance), bare-hand methods (where electricians are electrically bonded to the live conductor while insulated from ground), and insulating gloves rated for specific voltage levels. Each method requires intensive training and strict adherence to procedures to prevent accidents and ensure safety.

Through disciplined adherence to safety regulations, proper PPE usage, clearly defined work boundaries, and expert handling of live equipment, high voltage electricians play a vital role in maintaining both operational efficiency and personal protection on the job site. Learn how PPE fits into the hierarchy by browsing our Arc Flash PPE Category, including ratings and selection standards.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

The Challenges and Risks of High Voltage Work

Electrical power technicians face numerous challenges and risks while performing their duties. One of the most hazardous events they may encounter is an arc flash—a sudden, explosive release of electrical energy caused by a fault or short circuit that occurs through the air. Arc flashes generate intense heat (up to 35,000°F), ultraviolet radiation, and a powerful arc blast that can include molten metal, pressure waves, flying debris, and deafening sound levels. Without proper arc-rated PPE, these incidents can cause severe burns, permanent hearing or vision loss, lung damage, or death within milliseconds.

Technicians must also contend with environmental factors such as moisture, temperature extremes, and storms, which can compromise insulation or bring down overhead power lines. Ice buildup, lightning, and wind can increase the chance of faults, line breakage, or transformer failure, especially in exposed utility systems.

In modern industrial settings, particularly electric vehicle (EV) manufacturing and data centers, the use of High Voltage Direct Current (HVDC) systems introduces new risks. Unlike AC systems, HVDC can sustain continuous arcs without natural zero-crossing points, making faults more difficult to extinguish. Insulation breakdowns in HVDC equipment can cause persistent, high-energy discharges that escalate more quickly and with fewer warning signs. These environments demand specialized insulation materials, rapid shutdown systems, and advanced arc detection technology.

Combined with the physically demanding nature of the work—often performed at heights, in confined spaces, or under extreme conditions—these risks require a high voltage electrician to be in peak physical and mental condition. Precision, alertness, and adherence to strict safety procedures are essential, as a single mistake can result in catastrophic consequences for both the worker and the infrastructure they maintain. For a broader understanding of regulatory alignment, see our section on NFPA 70E Arc Flash Training, which emphasizes compliance and safety best practices.

The Role of Testing Equipment in High Voltage Work

Testing equipment is a vital tool for utility power electricians. These tools help electricians diagnose issues in electrical systems and verify the integrity of circuits and connections. By using specialized testing equipment, electricians can identify faults such as broken wires, short circuits, or faulty circuit breakers. This diagnostic process is crucial for maintaining the safety and efficiency of electrical distribution systems. Electrical power technicians are trained to use these tools effectively, enabling them to make informed decisions about repairs and replacements in the power grid.

A utility power technician is a specialized professional who plays a vital role in maintaining and repairing electrical power systems. They work with complex equipment, such as power lines and electrical power regulators, ensuring that electrical power is safely distributed to homes, industries, and businesses. These electricians are crucial for troubleshooting power distribution systems, resolving issues that can lead to electrical failures, and ensuring compliance with safety standards. With the proper training and expertise, utility power electricians ensure the reliable operation of electrical systems, preventing accidents and optimizing performance across the grid. Their work ensures that electricity continues to flow safely and efficiently, playing a key role in the stability of industrial and residential power systems.

A high voltage electrician is critical to the infrastructure of modern industry, energy, and transportation. Their expertise in system integrity, regulatory compliance, and risk management ensures the safe, uninterrupted flow of electrical power. Whether working on a wind farm, EV production facility, utility substation, or hospital backup system, their knowledge, skill, and discipline make them one of the most essential roles in electrical safety.

Contact us to learn more about our courses or request a free quotation.

Related Articles