How is Arc Rating Derived?

By R.W. Hurst, Editor

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

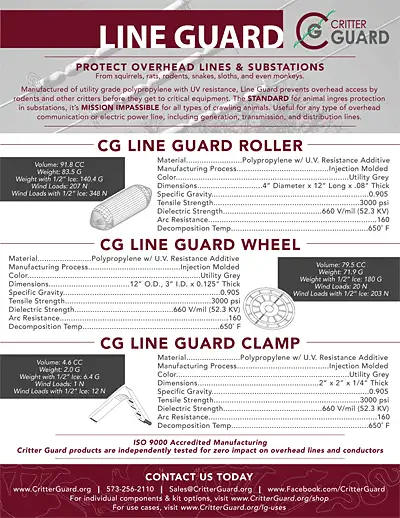

How is arc rating derived? Arc rating is determined through arc flash testing of PPE, measuring incident energy until failure, ensuring NFPA 70E safety compliance.

How is Arc Rating Derived?

It is derived from the determined ability of a fabric or material system to withstand the thermal and energy release of an electrical arc discharge without causing second-degree burns to the wearer.

✅ Determined by ASTM/IEC arc flash testing to measure PPE protection.

✅ Rated in cal/cm² based on incident energy exposure before failure.

✅ Ensures NFPA 70E compliance for worker electrical safety.

Arc rating is a critical measure in determining the protective capability of personal protective equipment (PPE) against the hazards of an electrical arc discharge. Understanding how arc rating (AR) is derived involves examining the standards, testing methods, and factors that influence this vital safety metric. To better understand how arc flash hazards influence PPE requirements, it’s important to know how arc ratings are tested and certified.

AR is derived from the determined ability of a fabric or material system to withstand the thermal and energy release of an electrical arc discharge without causing second-degree burns to the wearer. The rating is expressed in calories per square centimetre (cal/cm²), indicating the amount of incident energy a material can absorb before it reaches its protection limit. Selecting the right arc flash PPE clothing begins with understanding the garment’s arc rating and its cal/cm² protection level.

Electrical work carries inherent risks, with electrical arc flashes being a particularly dangerous one. An arc flash is a sudden and intense burst of electrical energy that can cause severe burns, explosions, and shrapnel injuries. Personal protective equipment (PPE) plays a crucial role in safeguarding workers from these hazards. This article explores the concept of AR, a critical metric used to evaluate the protective capabilities of clothing against electrical arc exposure.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

In the context of PPE, AR refers to a value attributed to a material system that indicates its performance when exposed to an electrical arc discharge. This rating essentially helps determine how well the material protects the wearer from the thermal energy released during an arc flash event. Workers should avoid the most common errors in arc flash analysis to ensure PPE arc ratings match actual incident energy exposure.

AR is derived from standardized testing procedures that evaluate a material system's ability to withstand the heat and energy released during an arc flash. These tests measure two key parameters:

-

Arc Thermal Performance Value (ATPV): This value represents the amount of incident energy (measured in calories per square centimeter, cal/cm²) a material system can withstand before there's a 50% probability of causing a second-degree burn through the material.

-

Energy of Breakopen Threshold (EBT): This value represents the incident energy level at which the material system exhibits a breakopen response. This doesn't necessarily indicate a burn, but rather a physical breakdown of the material that compromises its protective integrity.

AR is reported as either the ATPV or the EBT, whichever value is lower. This ensures a conservative approach to safety, prioritizing the burn protection offered by the material.

Frequently Asked Questions

What is the Definition of Arc Rating in the Context of PPE?

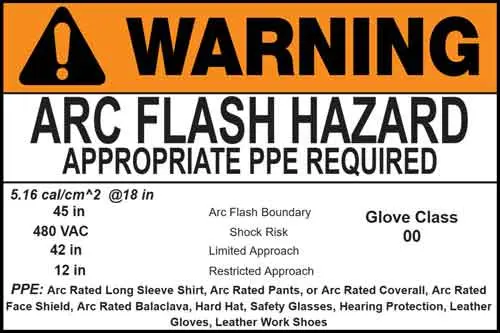

In the context of PPE, AR is the maximum incident energy that protective clothing can absorb without causing second-degree burns to the wearer, except for the hands. The rating is reported in cal/cm² and provides a standardized measure of the material's protective performance. This rating ensures that the PPE provides adequate protection against the specific energy levels encountered in potential arc flash hazards. In high-risk environments, a 40 cal arc flash suit may be necessary when arc testing indicates extreme heat and energy hazards.

What Standards are Used to Determine the Arc Rating of Protective Clothing?

Several standards and testing methods are employed to determine the AR of protective clothing. Key standards include:

-

ASTM F1959: This standard test method determines the AR of materials for clothing.

-

IEC 61482: This standard specifies test methods for determining the arc protection of clothing.

During the tests, fabrics are subjected to a high-energy electrical discharge, and their performance to exposure is measured. The incident energy exposure is recorded, and the ATPV or energy of break-open threshold is derived based on the material's response. NFPA 70E arc flash standards define the testing methods and PPE performance requirements behind arc ratings.

How is the Incident Energy Exposure Measured During Tests?

Incident energy exposure is measured using sensors placed on a mannequin dressed in the test fabric. The mannequin is subjected to an electrical arc discharge, simulating real-world conditions. Sensors capture the amount of energy that reaches the mannequin's surface, and this data is used to calculate the ATPV and EBT. The goal is to determine the level at which the material can protect the body, except for the hands, from second-degree burns.

Factors Influencing Arc Rating

Several factors can influence the AR of a fabric or garment:

-

Fibre Type: Certain fibres, like Nomex or aramid blends, inherently offer better thermal resistance than natural fibres like cotton.

-

Fabric Construction: The density, weave, and layering of the fabric affect its ability to absorb and dissipate heat.

-

Treatments and Coatings: Special treatments or coatings on the fabric can enhance its arc resistance.

-

Multi-layer Garments: Arc-rated clothing often consists of multiple layers, each contributing to the overall protective capability.

Understanding these factors allows manufacturers to design and develop clothing with targeted arc ratings for specific electrical hazards. Understanding incident energy measurement is critical for interpreting ATPV and EBT values during arc flash testing.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

How Does Arc Rating Correlate with the Level of Protection Provided to the Wearer?

The AR directly correlates with the level of protection provided to the wearer. A higher AR means the fabric can withstand greater incident energy before it fails or causes burns. This ensures that workers are adequately protected against the specific energy levels present in their work environment. For example, in a high-risk environment with potential exposure to high incident energy, PPE with a high AR is essential to prevent serious injuries.

AR is a crucial measure of the protective performance of PPE against electrical arc discharge hazards. Derived from standardized testing methods, it provides a clear indication of how much energy a material can absorb before causing harm. Factors such as material composition, fabric thickness, and construction play significant roles in determining the AR. By adhering to established standards and understanding the implications of AR, safety professionals can ensure that workers are adequately protected in hazardous environments. Ensuring proper PPE selection based on AR is essential for maintaining safety and preventing injuries in the workplace.

Related Articles