LOTO Training – Lockout Tagout Safety

By R.W. Hurst, Editor

NFPA 70e Training - Arc Flash

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

LOTO training teaches workers to safely control hazardous energy during maintenance. It covers OSHA standards, lockout procedures, tagout devices, and energy isolation to prevent accidents and improve workplace electrical safety.

What is LOTO training?

LOTO training is safety instruction that teaches employees how to isolate and lock hazardous energy sources before servicing equipment.

✅ Ensures compliance with OSHA and CSA/ANSI standards

✅ Protects employees from electrical, mechanical, and hydraulic hazards

✅ Builds safer workplaces through documented procedures and retraining

Lockout Tagout (LOTO) training is crucial for safeguarding workers against the risks associated with hazardous energy sources during the maintenance or servicing of machines or equipment. This process involves isolating and controlling energy sources to prevent the unintended release of energy that could result in injuries, equipment damage, or even fatalities. LOTO is regulated by the Occupational Safety and Health Administration (OSHA) under 29 CFR 1910.147, commonly known as the Control of Hazardous Energy standard. For electrical workers and other personnel involved in such tasks, understanding and following proper LOTO procedures is critical for maintaining a safe work environment. To gain a deeper foundation in safety practices, see our detailed guide on Lockout Tagout, which explains its role in preventing workplace accidents.

Lockout Tagout training requirements emphasize that both authorized and affected employees must fully understand how to follow written energy control procedures and properly apply energy isolation devices. Without this knowledge, attempts to restart equipment during maintenance can put everyone at risk. Effective lockout tagout LOTO programs teach workers not only how to secure machines but also how to recognize when devices are in place and why communication between teams is essential. By reinforcing these skills through structured instruction, employers ensure compliance and strengthen workplace safety.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Request a Free Training Quotation

Why LOTO Training Matters

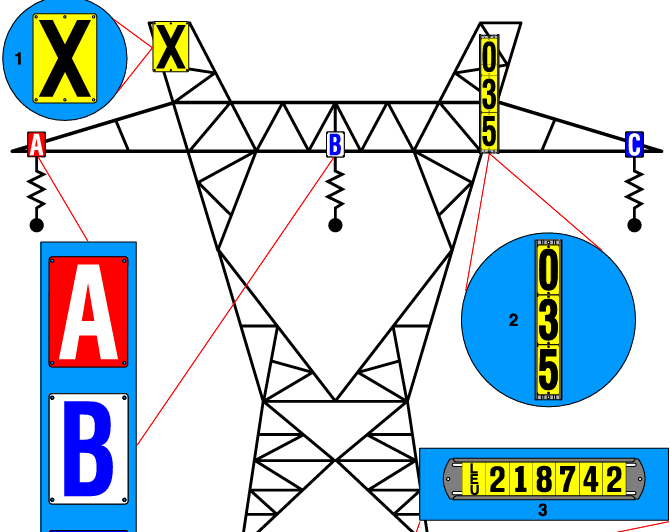

Through LOTO training, employees understand that hazardous energy is a leading cause of workplace accidents. Training emphasizes that even routine maintenance can lead to severe injuries or fatalities if proper procedures are not followed. By learning to implement OSHA’s 29 CFR 1910.147 Control of Hazardous Energy standard, or Canada’s CSA Z460 requirements, workers gain the ability to apply written energy control programs and follow them consistently. Compliance is essential, and our article on the OSHA Lockout Tagout Standard outlines the specific requirements under 29 CFR 1910.147.

Lockout Tagout training also highlights that hazards are not limited to electrical systems. Workers are taught how mechanical equipment, hydraulics, pneumatics, and other systems pose risks that require careful isolation and verification. For workers new to the concept, our resource, 'What is Lockout Tagout,' breaks down the basics of hazardous energy control.

Common Hazardous Energy Types

Lockout Tagout training helps workers recognize the full range of hazardous energy sources they may encounter. Employees are taught that safety requires controlling far more than electricity alone.

-

Electrical – live circuits, exposed wiring, stored capacitors

-

Mechanical – moving machine parts or springs under tension

-

Hydraulic – pressurized oil lines, rams, or actuators

-

Pneumatic – compressed air systems and valves

-

Chemical – reactive or pressurized substances

-

Thermal – hot surfaces, steam lines, or extreme cold

-

Gravitational – suspended parts or elevated loads that can fall

By learning to identify all of these hazards during training, workers can ensure every energy source is properly isolated before servicing equipment. To better understand the written program elements, consult our overview of OSHA Lockout Tagout Requirements and how they apply across industries.

Steps in a Proper LOTO Procedure

In training, employees are taught that lockout tagout is not a single action but a methodical process. They practice following six core steps that eliminate hazards before work begins.

-

Preparation – Identify all energy sources and review the written procedure.

-

Shutdown – Power down equipment according to manufacturer or site protocols.

-

Isolation – Disconnect equipment from its energy sources using switches, valves, or breakers.

-

Lockout/Tagout Application – Attach locks and tags to each isolation point to prevent reconnection.

-

Stored Energy Relief – Release or block residual energy such as compressed air, hydraulic pressure, or spring tension.

-

Verification – Test controls to confirm zero energy before work begins.

LOTO training emphasizes that tagout devices are not just labels; they are vital communication tools that alert everyone in the area that equipment must not be re-energized. Step-by-step guidance is available in our detailed breakdown of the Lockout Tagout Procedure, ensuring workers know how to isolate and verify energy sources.

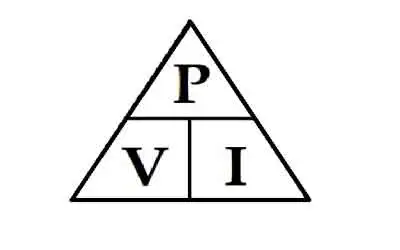

Lockout vs Tagout

Lockout Tagout training explains the difference between the two methods. Workers are taught that lockout is the preferred practice because it physically prevents energy reconnection, while tagout serves only as a warning. Training ensures employees understand OSHA’s requirement that tagout alone is acceptable only when it provides equivalent protection to lockout and that additional safeguards may be required.

Roles and Responsibilities

LOTO training clearly defines the responsibilities of different employee groups so there is no confusion about who does what.

-

Authorized employees learn how to perform the full lockout/tagout procedure, including energy isolation and verification.

-

Affected employees are trained to understand the purpose of locks and tags so they never attempt to operate equipment under lockout.

-

Other employees are instructed to recognize warning tags and devices and stay clear of equipment under lockout conditions.

By teaching these distinctions, Lockout Tagout training ensures every worker contributes to maintaining safe conditions.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Components of a LOTO Program

Training also teaches employees that effective lockout tagout goes beyond individual actions. Workers learn about the program elements that employers must provide to support safety:

-

Written Procedures – step-by-step instructions for each machine

-

Periodic Inspections – audits to verify compliance and close gaps

-

Retraining Requirements – instruction whenever job assignments, equipment, or procedures change

-

Contractor Coordination – ensuring outside personnel follow site rules

-

Documentation – records of training, inspections, and corrective actions

By understanding these program components, employees see how their individual responsibilities fit into a larger system of safety.

Common Mistakes and How to Prevent Them

Lockout Tagout training also prepares workers to recognize and avoid frequent errors. Employees learn that failing to isolate every energy source, applying locks incorrectly, skipping verification, or communicating poorly with coworkers can all lead to serious accidents. Training reinforces why each step matters and how refresher courses correct bad habits before they become dangerous.

Example: Why LOTO Saves Lives

Training often uses real or hypothetical examples to show why procedures are critical. Imagine a hydraulic press still holding pressure in its lines. Without a proper lockout, a mechanic begins repairs. A coworker unknowingly restores power, and the press cycles, causing injury. Training shows how proper shutdown, lockout, tagout, stored energy relief, and verification would have prevented the accident.

Lockout Tagout training is more than a compliance requirement. It equips workers with the knowledge, skills, and confidence to recognize hazardous energy, follow established procedures, respect their roles, and prevent mistakes. By completing training and refresher courses, employees create safer workplaces while employers meet OSHA and CSA standards. Ultimately, lockout tagout training is about protecting lives and embedding safety into every maintenance task.

Related Articles

-

To clear up common issues, explore Lockout Tagout Questions, where frequently asked topics are explained in detail.

- For hands-on learning and compliance, our dedicated Lockout Tagout Training course page provides practical instruction to reinforce these critical safety skills.

To ensure compliance and worker protection, The Electricity Forum offers specialized Construction Electrical Safety Training, including NFPA 70E Training and CSA Z462 Arc Flash Training courses. Request a free training quotation today to equip your team with the knowledge and skills they need to stay safe on the job.