What Does VFD Stand For?

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

A VFD stands for Variable Frequency Drive, also known as an adjustable frequency drive or AC drive, controls motor speed and torque by varying voltage and frequency, thereby helping systems conserve energy, reduce wear, and enhance process performance across various applications.

What Does VFD Stand For?

A VFD is a vital technology in electrical engineering and industrial maintenance, and it plays a transformative role in modern motor control systems.

✅ Improves energy efficiency and reduces operating costs

✅ Extends equipment lifespan with smoother motor control

✅ Enhances process performance and system reliability

Electric Motor Testing Training

Request a Free Training Quotation

For professionals in these fields, understanding VFDs is essential due to their ability to enhance efficiency, optimize energy use, and improve the performance of electric motors. By varying the frequency and voltage of the power supply, VFDs enable precise control over speed and torque, making them indispensable for applications ranging from conveyor belts in manufacturing to HVAC systems in commercial buildings. With their impact on sustainability, cost savings, and operational reliability, motor controls are at the forefront of innovation in industrial automation. Precise electric motor control is a primary reason why VFDs are essential in industrial and commercial systems.

A modern variable speed drive relies on advanced semiconductor components such as the insulated gate bipolar transistor IGBT to regulate power efficiently. By converting incoming line voltage into controlled pulses, the system uses pulse width modulation PWM to shape the output waveform. This precise control enables the drive to dynamically adjust motor load, ensuring smoother operation, improved efficiency, and extended equipment life.

VFD Core Operation and Motor Speed Control

At its core, a VFD converts an AC power supply into a form that allows for precise control of a motor's speed and torque. The process begins with a rectifier, which converts AC power into DC power. A stabilized DC link then ensures smooth operation, while an inverter—powered by advanced components such as insulated gate bipolar transistors—transforms the DC power back into AC power, but with variable frequency. This sophisticated operation enables a motor to run at speeds that perfectly match the demands of a given task, offering unparalleled flexibility and efficiency. To understand how these drives function, see our guide on how does a VFD work, which explains rectifiers, inverters, and frequency conversion.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

VFD Technology Overview

| Aspect | Details | Purpose / Benefit |

|---|---|---|

| Input Power | Receives standard AC supply (typically 50/60 Hz) | Provides source energy for conversion |

| Rectifier Stage | Converts AC power to DC power | Creates a stable intermediate power source |

| DC Link | Smooths and stabilizes the DC using capacitors/inductors | Ensures steady flow before inversion |

| Inverter Stage | Uses IGBT transistors and PWM to convert DC back to AC at variable frequency | Controls motor speed and torque precisely |

| Output to Motor | Variable frequency and voltage supplied to the motor | Matches motor speed to load requirements |

| Main Advantages | Energy savings, reduced wear, improved process control, extended equipment life | Efficiency, sustainability, cost reduction |

Benefits of Adjustable Frequency Drives

Industries rely on VFDs to optimize performance and energy consumption. Conveyor belts in assembly lines often require varying speeds to accommodate different production phases, which a VFD enables to be done seamlessly. Similarly, HVAC systems use motor controls to regulate airflow, ensuring comfort while minimizing energy use. By allowing motors to operate at partial rather than full speed when maximum output is unnecessary, these devices help save energy, reduce wear, and extend the lifespan of equipment. In an era of environmental consciousness, the role of motor controls in sustainability cannot be overstated.

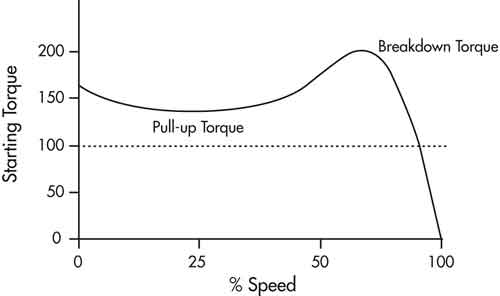

Benefits of Motor Control

The benefits of motor controls extend beyond energy savings. These devices reduce mechanical stress on motors by allowing gradual acceleration and deceleration, which is crucial for heavy-duty applications such as operating phase AC motors or single-phase systems. For example, a variable frequency drive VFD can ensure smooth startups for high-frequency industrial machines, mitigating the risk of mechanical failure. This capability is particularly valuable in industries where reliability and longevity of equipment are critical. Because VFDs directly influence energy use, they play a significant role in improving electric motor efficiency across various industries.

VFD Types

There are several types of VFDs, each tailored to specific needs. The Volts-per-Hertz control method is a versatile option suitable for general applications, offering straightforward control of an AC motor. For more demanding tasks requiring precision, vector control and direct torque control (DTC) provide enhanced accuracy in managing speed and torque. These advancements ensure that every type of motor controller meets the exacting standards of modern industries, whether for simple or complex operations. For a comprehensive overview of applications and benefits, visit our Variable Frequency Drive Resource page.

VFDs in Industrial Automation and IoT

The integration of motor controls with advanced technologies has opened new frontiers in industrial automation. IoT-enabled systems now incorporate VFDs to provide real-time data for predictive maintenance and operational optimization. In manufacturing, VFDs paired with smart systems can control the speed of motors in conveyor belts based on dynamic production requirements. These innovations not only improve efficiency but also provide valuable insights into operational performance, creating a feedback loop that fosters continuous improvement.\\VFDs and Syust

Sustainable Motor Control Solutions

VFDs are also reshaping the sustainability narrative by reducing energy consumption and minimizing carbon footprints. Industries can significantly lower their environmental impact by utilizing motor controls to optimize motor operation. The ability to control the speed and torque of electric motors ensures energy is used only when and where it is needed, aligning with global efforts to reduce waste and conserve resources. In many operations, synchronous motors are paired with VFDs to deliver constant speed and reliable performance.

Future of AC Motor Drive Technology

The future of motor control technology is equally promising. Emerging trends such as the adoption of silicon carbide semiconductors promise greater efficiency and smaller device sizes. Wireless control capabilities are also being explored, paving the way for even more versatile applications. These innovations will further enhance the role of motor controls in industrial automation and energy management.

The question, "What does VFD stand for?" goes beyond defining the term. It encompasses an entire ecosystem of innovation, efficiency, and sustainability. From controlling the speed of an AC motor to enabling smart, energy-efficient systems, the VFD continues to revolutionize the way industries operate. As technology evolves, so too will the capabilities, cementing their place as indispensable tools in the modern industrial landscape.

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.