Time Delay Relay

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

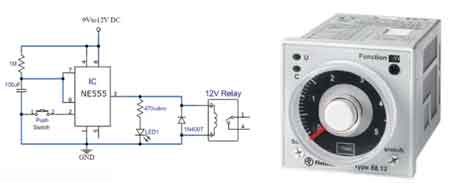

A time delay relay controls the timing of electrical circuits by delaying switching operations. Commonly used in HVAC systems and motor control, it enhances safety, prevents equipment damage, and ensures proper sequencing of electrical processes.

What is a Time Delay Relay?

A time delay relay plays a crucial role in modern electrical and automation systems, providing precise control over when electrical circuits are activated or deactivated. It:

✅ Delays circuit activation or deactivation to control timing.

✅ Improves automation and motor start-up sequencing.

✅ Protects equipment by preventing sudden electrical surges.

Unlike standard relays that switch instantly upon receiving a signal, these devices introduce a controlled pause before engaging or disengaging a circuit. This functionality has become essential for various industrial, commercial, and residential applications, providing operational flexibility and safety enhancements. A time delay relay works alongside other protective devices, such as circuit breakers, to ensure reliable power system protection.

Basic Protection Relay Training

Request a Free Training Quotation

Types of Time Delay Relays

One of the most important aspects of understanding time delay relays is recognizing the different types available. Each type serves a distinct purpose, enabling tailored control of electrical systems. On-delay relays, for example, introduce a set period before activating a circuit once a signal is received. This type is often used in motor control applications where gradual power engagement is necessary. Off-delay relays, by contrast, maintain power to a circuit for a specified period after the signal is lost, commonly seen in lighting control systems that allow lights to remain on briefly after a switch is turned off. Interval timer relays offer an additional function by activating and deactivating circuits for specific intervals, making them particularly useful in repetitive operations, such as conveyor belt control. Multi-function protective devices combine these features into a single, versatile unit, providing users with multiple timing options in one device. Unlike a standard relay, a delay relay can be combined with multifunction relays to provide more advanced timing and coordination features.

Test Your Knowledge About Electrical Protection!

Think you know Electrical Protection? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Applications Across Industries

The applications of delay relays are extensive, spanning multiple industries. In industrial automation, they are essential for controlling sequential operations in machinery, ensuring that each step occurs in the correct order. For example, in motor start-up sequences, time delay relays enable staggered activation, preventing power surges that could damage equipment. In HVAC systems, these protective devices manage the precise timing of fan operations, damper movements, and system shutdowns to optimize energy efficiency. Lighting control systems also benefit from time delay functionality, enabling scheduled on-off cycles, emergency lighting activation, and dimming effects for improved energy management. Security systems utilize these relays to trigger alarms, control access points, and activate security cameras at the precise moment, ensuring a rapid and precise response to detected threats.

Selecting the Right Delay Relay

Selecting the right time delay relay for a particular application requires consideration of several key factors. The voltage rating is crucial, as the protective device must be compatible with the system’s operating voltage. The time range is another vital factor, as different applications require different delay durations. Whether the delay requires a few milliseconds or several minutes, selecting a protective device with the correct range is essential. Contact configuration also matters, as some applications require normally open (NO) contacts, while others need normally closed (NC) contacts. Additionally, the mounting style must be evaluated based on the physical space available for installation. Environmental conditions, such as temperature, humidity, and vibration, should also be considered to ensure the protective device's longevity and reliability in challenging conditions. Proper coordination between a relay and circuit breaker is essential when incorporating delay relays into automation or motor control systems.

Troubleshooting and Maintenance

Despite their reliability, time delay relays can experience operational issues. Troubleshooting these devices involves identifying and resolving common issues such as incorrect wiring, power supply interruptions, and component failures. One frequent issue is inaccurate timing, which may be caused by wear and tear or poor calibration. Visual inspection can reveal obvious faults, such as loose wires or signs of damage. Voltage measurements help verify power supply issues, while testing individual components can detect internal malfunctions. Calibration is also critical to ensure that timing settings are accurate, as improper calibration can lead to equipment malfunctions. Preventive maintenance is a proactive approach to avoid such issues. Regular cleaning, lubrication, and inspection of contacts can significantly extend the lifespan of the protective device, ensuring consistent performance. In high-demand environments, a delay relay may be paired with complex protective relays to sequence multiple operations safely and efficiently.

The Future of Delay Relays

The technology behind time delay relays continues to evolve. Traditionally, electromechanical devices dominated the market, but modern solid-state protective devices are now gaining popularity. Solid-state designs eliminate moving parts, reducing wear and increasing durability. These protective devices are also faster and more precise, making them ideal for applications that require high-speed switching. Another technological advancement is the use of microprocessor-based protective devices. Modern automation often uses delay relays in combination with solid state relays, which offer faster switching and greater reliability.

These devices incorporate advanced features, including programmable timing functions and communication capabilities. They enable operators to remotely customize delay settings, which is particularly useful in large-scale industrial automation systems. The rise of IoT (Internet of Things) integration has also influenced the design of time delay relays. By connecting protective devices to IoT networks, operators can remotely monitor and control them, providing access to real-time updates and predictive maintenance alerts. This connectivity is a game-changer for industries seeking to enhance operational efficiency.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Energy efficiency is another area where time delay relays are making an impact. Modern designs incorporate features that reduce power consumption during idle periods. This is especially beneficial in large-scale industrial facilities where energy costs are significant. By optimizing the use of protective devices, companies can reduce energy waste and enhance overall system efficiency. Additionally, eco-friendly designs are emerging, with manufacturers producing relays made from sustainable materials and employing production processes that have a lower environmental impact. Engineers designing motor or transformer protection systems often use delay relays with short circuit protection and overcurrent protection to prevent equipment damage.

Frequently Asked Questions

What is the purpose of the time delay?

The purpose of a time delay is to control the timing of electrical circuits and devices by delaying the activation or deactivation of connected equipment. Time delays are used to sequence events, prevent short cycling, avoid inrush currents, and ensure the safe operation of electrical systems. They are commonly applied in industrial control systems, motor protection, and lighting systems, among other applications.

What is the trigger on a time delay relay?

The trigger on a time delay relay is the event or signal that initiates the timing sequence of the device. This trigger can be a change in voltage, current, or the state of a control input (like a push button, limit switch, or control signal from a PLC). Once the trigger is activated, the protective device initiates its timing operation, which can either delay or accelerate the energizing or de-energizing of its output contacts, depending on the mode of operation.

What are the four modes of time delay relays?

The four main modes of time delay relays are:

-

On-Delay: It waits for a preset time after the trigger is activated before closing its output contacts. This mode is used to delay the start of devices, such as motors or lighting.

-

Off-Delay: It maintains its output contacts in the "on" position for a preset time after the trigger is deactivated. This is used for applications like keeping equipment running for a short period after power is removed (e.g., exhaust fans).

-

Interval On: This device immediately activates its output contacts when the trigger is activated, but only for a preset time, after which the contacts return to their original state. This is used for tasks like short-term activation of alarms or indicator lights.

-

One-Shot (Single Shot): The output contacts activate for a fixed time period when the trigger is applied, regardless of how long the trigger is held. This is used in applications where a single action or pulse is required, such as starting a machine repeat cycle or generating a pulse signal.