Understanding Your Electrical Cables

By R.W. Hurst, The Electricity Forum

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Know your electrical cables with guidance on wire types, gauges, insulation, voltage ratings, amperage, grounding, color codes, NEC compliance, copper vs aluminum conductors, shielding, and safe installation best practices for home and industrial applications.

What Is Know Your Electrical Cables?

An expert guide to identify cable types, match ratings to loads, and install wiring safely to code.

✅ Choose correct gauge, insulation, and voltage rating

✅ Distinguish THHN, NM-B, MC, and flexible cord types

✅ Follow NEC color codes, grounding, and ampacity limits

The electrical conductors strung between the poles and towers of overhead powerlines are usually bare wires without an insulation covering. An electrical cable is generally defined as being an insulated electrical conductor. This information sheet does not discuss uninsulated wires and focuses only on insulated cables.

This information sheet is not meant to provide the reader with an in-depth knowledge of cable sizing, selection or methods of installation. It is meant to provide:

1. A general appreciation of the factors that should be generally considered when confronted with cabling information; and

2. A general understanding on what is involved in sizing and installing electrical cables.

For procedural guidance on field workmanship, the installation of conductors and cables resource outlines good practice without prescribing specific designs.

THEORY

The sole function of an electric cabling system is the transfer of electric power. The load to be supplied can vary from a small indicating lamp to a large generator transformer.

For background on how materials conduct charge, the conductor of electricity overview clarifies current flow and resistance considerations.

Any cabling system must meet the following requirements:

SAFETY

1. The cable must be able to withstand the voltage to which it will normally be subjected; Routine power cable test methods validate insulation integrity under expected stresses.

Test Your Knowledge About Wiring Devices!

Think you know Wiring Devices? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

2. A cabling system must be installed in such a manner that it presents no danger to any person likely to come in contact with the cables; Practical cable handling and testing procedures help verify these safety measures during commissioning.

3. The cables must not develop a hazard by induction, or through other means, in other equipment; and

4. The type of insulation must suit the type of installation and the environment. The temperature rating of the cable must be suited to ambient conditions. Also, if the cable is to be installed where it is subject to direct sunlight, resistance to UV becomes a factor. If the cable is to be installed in an area where it is subject to flammable dust or liquid, additional factors must be considered. Design notes for aerial cable installations highlight UV exposure and clearances in outdoor runs.

CONDUCTOR SIZING

The cables must be able to conduct power in a manner that will allow the connected device to operate to its full capacity. The cable must be able to conduct the full load current without causing any significant voltage drop at the terminals of the load connection. In considering this factor, the starting current requirements of the connected device have also to be taken into consideration and the cable must be able to withstand a fault on the system to which it is connected.

INSTALLATION REQUIREMENTS

1. The installation of cables Wiring Rules;

2. The cable support must protect the cable from any reasonable chance of damage; and

3. The cable also must be protected from the detrimental effects of the environment in which the cable is installed.

EF Partner Media

Guidance on installation of cable in cable trays addresses support spacing and mechanical protection.

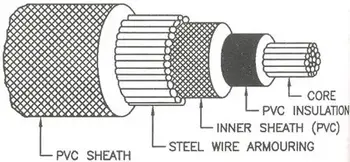

CABLE CONSTRUCTION

CONDUCTORS

Copper and aluminium are the materials most used for conductors. Aluminium conductors of cross-sectional area less than 16 mm2 have proved difficult to terminate due to their tendency to ‘cold flow’. Therefore below 16 mm2, aluminium cables are not generally used.

Copper is a better conductor than aluminium. To achieve the same current flow as a copper conductor, an aluminium conductor would need to have 1.6 times the cross sectional area. Because of the equivalent aluminium conductor requiring a larger cross sectional area than that of copper, the size of the cable is larger. This will result in greater space required to terminate an aluminium conductor than a copper conductor of equivalent current carrying capacity. The termination of an aluminium conductor requires great care to avoid problems due to the formation of aluminium oxide on the metal surface, which will interfere with the conductivity of the termination. In underground networks, copper underground transmission applications often exploit copper's higher conductivity for compact routing.

Normally aluminium conductors cost less than copper conductors. Aluminium conductors have approximately half the specific gravity as copper conductors.

The decision on which conductor to be used in the cable will require the above factors to be considered.

INSULATION

The type of insulation is influenced by a number of factors such as:

1. The maximum operating voltage of the cable; and

2. The temperature the cable has to withstand. This influences the quality and type of the insulation, coverings, sheathings, insulating sleeves on connections and sealing compounds used on the cable.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

The current carrying capacity for Mineral Insulated Metal Sheathed (MIMS) cables are based on an operating temperature of 100°C for the external surface of either bare metal sheathed or served cables. Higher continuous operating temperatures are permissible for bare metal sheathed cables, dependEnt upon factors such as:

1. The suitability of the cable terminations and mountings;

2. The location of the cable away from the combustible materials;

3. The location of the cable away from areas where there is a reasonable chance of persons touching the exposed surface; and

4. Other environmental and external influences. The minimum temperature of use of MIMS cables will be dependent on the cable seal used and manufacturer’s recommendations should be followed.

From: Wire and Cable and Wiring Methods Handbook, Vol 3, The Electricity Forum