OLTC Transformer Explained

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

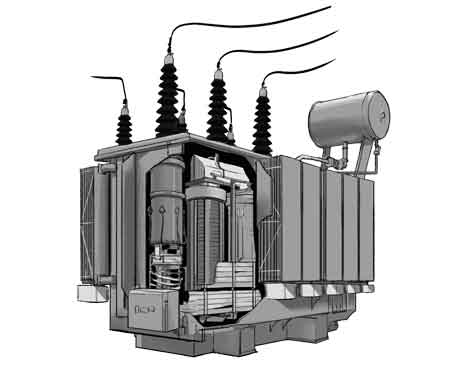

An OLTC transformer, or On-Load Tap-Changer, is a critical component in power distribution systems. It regulates transformer output voltage without interrupting the power supply. By adjusting tap positions under load, it supports substations, utilities, and industrial applications.

What is an OLTC Transformer?

An OLTC transformer is designed with a tap-changing mechanism that allows for the modification of the winding ratio in real-time. This enables utilities to maintain voltage stability and grid performance without having to shut down equipment. Key benefits include:

✅ Maintains voltage stability under varying load conditions

✅ Enhances grid reliability and power quality

✅ Reduces outages and operational downtime

This capability is essential for maintaining a stable and reliable power supply, especially during periods of fluctuating demand or system disturbances. OLTC transformers play a vital role in modern utility transformers, where consistent voltage regulation ensures safe and efficient power delivery across the grid.

Unlike traditional de-energized tap changer (DETC) systems, OLTC technology operates under load, enabling precise, real-time control of voltage levels. This ensures a consistent flow to end-users and avoids costly downtime. In distribution networks, OLTC technology complements the operation of a distribution transformer, helping utilities manage fluctuating loads without service interruption.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Types of OLTC: Resistor, Reactor & Vacuum Switching

On-Load Tap-Changers are commonly built in three variants:

-

Resistor-type OLTC – uses resistors during tap transitions, offering reliable operation but higher energy dissipation.

-

Reactor-type OLTC – employs reactors for smoother switching, suitable for high-power applications.

-

Vacuum switching OLTC – a modern design that uses vacuum interrupters, minimizing arcing, wear, and maintenance needs.

Most OLTCs use make-before-break switching, ensuring that one tap is established before the other is disconnected. This seamless process prevents interruptions, equipment stress, or voltage spikes—much like how an automatic transmission shifts gears smoothly without disengaging power. High-voltage installations often pair OLTC systems with electrical substation transformers to maintain stability and mitigate risks associated with voltage spikes.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Voltage Regulation: A Core Function

A typical OLTC offers ±10% regulation through 33 tap positions (16 above, 16 below, and a neutral position). Each tap step adjusts the transformer’s output voltage by about 0.625%, allowing precise fine-tuning to meet grid and load demands.

The mechanism—comprising selector switches, diverter switches, and sometimes resistors or reactors—modifies the turns ratio in real-time, ensuring the voltage remains within safe operational limits. The precision of OLTC tap adjustments is critical to the performance of three-phase transformers, which are widely used in industrial and commercial applications.

Enhancing Power System Reliability

Voltage fluctuations, even minor ones, can cause cascading failures across power systems. OLTC transformers mitigate this risk by dynamically adjusting tap positions to maintain stability. By doing so, they prevent equipment short-circuits and maintain uninterrupted service during demand swings. High-voltage installations, especially those equipped with OLTC transformers, rely on them for dependable grid performance.

Optimizing Energy Efficiency

Traditional DETC systems require shutdowns for voltage adjustments, leading to inefficiency and delays. In contrast, OLTC transformers continuously optimize voltage, reducing reactive power losses and minimizing energy waste.

Resistor-type and reactor-type OLTCs dissipate some energy during operation, whereas vacuum switching OLTCs improve efficiency by minimizing losses and extending the life of components.

Prioritizing Safety

The ability to adjust voltage without de-energizing greatly enhances safety. Operators are not exposed to risks associated with manual adjustments, and the diverter switch isolates the switching process, minimizing arcing and short circuits. In high-voltage substations, this design ensures smooth, controlled transitions that safeguard both workers and equipment.

Regular Maintenance and Inspection

Because OLTCs have moving parts, they are prone to wear. Studies show that up to 30% of transformer failures are linked to OLTC mechanisms, underscoring the need for proactive maintenance.

Common diagnostic and monitoring methods include:

-

Oil & insulation analysis (DGA testing, particle profiling)

-

Static and dynamic resistance measurement (DVtest)

-

Vibro-acoustic or motor-current analysis to detect arcing and mechanical wear

Routine inspections—checking selector switches, diverter switches, and resistive/reactive components—extend lifespan and prevent outages. Maintenance protocols often include oil analysis, electrical testing, and monitoring mechanical wear. Effective condition monitoring is essential for OLTC transformers, as these components account for a significant share of transformer failures.

Technical Aspects of OLTC Transformers

The OLTC mechanism adjusts winding turns by shifting tap positions. A selector switch first prepares the next tap, a diverter switch transfers the load, and resistors/reactors or vacuum interrupters manage the energy released during transition.

Each tap position corresponds to a distinct turns ratio. By carefully choosing the tap step size, utilities maintain voltage within permissible limits. With 33-step regulation and ±10% control, OLTC systems deliver precision unmatched by manual tap changers. When integrated with transformer insulation and oil systems, OLTC mechanisms benefit from extended reliability and reduced maintenance risks.

Frequently Asked Questions

What is the difference between LTC and OLTC?

The primary difference between LTC (Load Tap Changer) and OLTC lies in the operation mode.

-

LTC (De-energized Load Tap Changer): Requires de-energizing the unit to change taps, interrupting the supply.

-

OLTC (On-Load Tap Changer): Adjusts taps while the system is energized, providing a continuous supply.

What is the function of a tap changer transformer?

It regulates voltage by adjusting the number of winding turns. In OLTCs, this is achieved seamlessly under load, ensuring reliability and stability.

What is the difference between resistor and reactor OLTCs?

Resistor-type OLTCs dissipate energy during switching, while reactor-type OLTCs provide smoother transitions in high-power applications.

What are the disadvantages of OLTC transformers?

-

Mechanical wear on selector and diverter switches

-

Potential malfunctions due to complexity

-

Noise and vibration during operation

-

Higher cost than DETC systems

Despite these challenges, the benefits in voltage regulation, grid reliability, and energy efficiency make OLTC transformers indispensable in modern power systems.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue