Power Transformer Explosion Causes And Prevention

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Power transformer explosions pose a serious risk to electrical substations, causing fires, equipment damage, and power outages. Proper maintenance, insulation monitoring, and the use of protective relays help reduce hazards and improve grid reliability.

What is a Power Transformer Explosion?

A power transformer explosion is a catastrophic failure in high-voltage equipment that can result from insulation breakdown, overheating, or internal arcing.

✅ Leads to fire, smoke, and equipment destruction

✅ Causes blackouts, downtime, and safety hazards

✅ Preventable with testing, monitoring, and protection

A power transformer explosion is a serious concern for industrial electricians, posing a significant safety hazard and the potential for widespread power outages. Understanding the causes, consequences, and preventative measures associated with these incidents is crucial for maintaining a safe working environment and ensuring the reliable operation of electrical systems. Let's examine the causes of explosions, covering key topics such as common causes of failure, the devastating effects of explosions, essential safety features, and best practices for maintenance, inspection, and prevention. By gaining a deeper understanding of these critical aspects, industrial electricians can enhance their knowledge, improve safety protocols, and contribute to preventing catastrophic transformer failures.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Causes of Transformer Explosions

A power transformer explosion can occur due to various internal and external factors. Internal faults, such as insulation breakdown, short circuits within the windings, and overheating due to excessive current flow, can trigger a catastrophic failure. External factors, including lightning strikes, power surges from the grid, and even animal intrusion, can also damage the unit and lead to an explosion. Overloading the unit beyond its designed capacity, as well as poor maintenance practices that neglect regular inspection and upkeep, can significantly increase the risk of such incidents. Many failures occur in high-voltage environments, making a substation transformer especially prone to catastrophic explosions if not properly maintained.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Effects of Transformer Explosions

The effects of a transformer explosion can be devastating. The immediate consequence is often a widespread power outage, disrupting electricity supply to homes, businesses, and critical infrastructure. The intense heat and release of flammable oil during an explosion can ignite fires, causing further damage to property and endangering lives. Additionally, transformer explosions can lead to environmental damage due to oil spills and the release of toxic gases, posing risks to both human health and ecosystems. The safety hazards associated with these events cannot be overstated, as explosions can cause serious injuries or even fatalities to people in the vicinity. Regular monitoring, such as using a hydrogen detection system, can help identify early fault conditions that often lead to explosions.

Transformer Safety Features

To mitigate the risks associated with transformer explosions, various safety features are incorporated into the design of transformers. Pressure relief valves are crucial components that release excess pressure buildup inside the unit tank, preventing it from rupturing. Buchholz relays act as sensitive detectors, sensing gas accumulation within the device, which often indicates an internal fault, and triggering a trip mechanism to isolate the faulty equipment. Overcurrent protection devices, such as fuses and circuit breakers, interrupt excessive current flow, preventing overheating and potential explosions. Preventive measures, such as condition monitoring, in an age of modernization provide operators with tools to detect insulation breakdowns and prevent failures.

Transformer Maintenance and Inspection

Regular maintenance and inspection are vital for ensuring the safe and reliable operation of power transformers. This includes visual checks for signs of damage or deterioration, oil analysis to assess its condition and identify potential issues, and electrical testing to evaluate the integrity of the unit's insulation and windings. Preventive maintenance, including cleaning, tightening connections, and replacing worn-out components, is crucial in preventing premature failures. Proper training for personnel working with transformers is crucial to ensure they understand the risks involved and follow safe operating procedures. The role of transformer insulation is crucial, as its deterioration is one of the leading causes of transformer explosions.

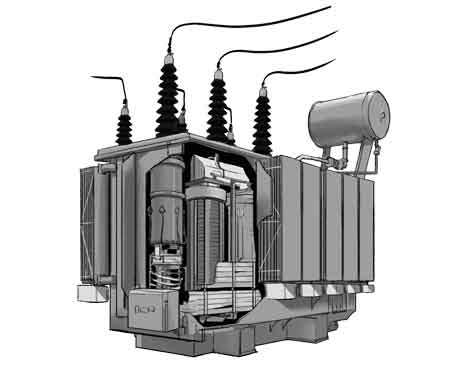

Transformer Types and Applications

Power transformers come in various types, each designed for specific applications. Large power transformers are used in power generation and transmission networks, while smaller distribution types step down the voltage for residential and commercial use. Instrument units serve a critical role in measurement and protection systems, ensuring the accurate monitoring and safe operation of electrical equipment. Learning about the construction of a transformer highlights how design features such as pressure relief valves and bushings affect explosion risk.

Transformer Oil

Oil plays a critical role in the operation and longevity of these devices. It serves as an insulator, preventing electrical breakdown between the windings, and as a coolant, dissipating the heat generated during operation. Different types of transformer oil are available, including mineral oil, silicone oil, and ester oil, each with its own characteristics and applications.

Transformer Explosion Case Studies

Analyzing real-world case studies of transformer explosions provides valuable insights into their causes and consequences. By examining what went wrong in previous incidents, engineers and operators can learn valuable lessons and implement preventive measures to avoid similar occurrences. These case studies also highlight the importance of proper maintenance, adherence to safety standards, and prompt response to potential issues.

Transformer Standards and Regulations

Various standards and regulations govern the design, installation, and operation of power transformers to ensure safety and reliability. IEEE standards provide comprehensive guidelines for design, testing, and maintenance, while NFPA codes focus on fire safety regulations for electrical equipment. Local regulations may also impose specific requirements for installation, ensuring compliance with regional safety codes.

Transformer Explosion Prevention

Preventing transformer explosions requires a multifaceted approach that encompasses proper installation, regular maintenance, and adherence to safety protocols. Ensuring adequate ventilation and grounding during installation is crucial for preventing overheating and electrical hazards. Following manufacturer recommendations for maintenance, including periodic inspections and oil testing, is essential to identify and address potential issues before they escalate. Implementing overload protection using appropriate fuses and circuit breakers safeguards the unit from excessive current flow.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Transformer Explosion Investigation

When a transformer explosion occurs, a thorough investigation is necessary to determine the root cause and prevent similar incidents in the future. This involves a comprehensive scene assessment to gather evidence and document the damage, followed by data analysis to review operational data and maintenance records. The final step involves a root cause analysis to identify the underlying factors that contributed to the explosion, enabling corrective actions and improvements to safety protocols.

By understanding the various aspects of power transformer explosions, from their causes and effects to prevention and investigation, we can work towards minimizing the risks associated with these critical components of our electrical infrastructure.

Frequently Asked Questions

What causes a power transformer to explode?

Several factors can cause a power transformer to explode, including:

-

Internal faults: Insulation breakdown, short circuits, and overheating.

-

External factors: Lightning strikes, power surges, and animal intrusion.

-

Overloading: Exceeding the unit's capacity.

-

Poor maintenance: Lack of regular inspection and upkeep.

What are the potential hazards of a power transformer explosion?

A power transformer explosion poses several hazards, such as:

-

Power outages: Disruption of the electricity supply.

-

Fires: Release of flammable oil and materials.

-

Environmental damage: Oil spills and the release of toxic gases.

-

Safety hazards: Risk of injury or death to people nearby.

How can a power transformer explosion be prevented or mitigated?

They can be prevented or mitigated through:

-

Regular maintenance and inspection: Including visual checks, oil analysis, and electrical testing.

-

Proper installation: Ensuring adequate ventilation and grounding.

-

Overload protection: Using appropriate fuses and circuit breakers.

-

Safety features: Utilizing pressure relief valves, Buchholz relays, and other protective devices.

-

Adherence to standards and regulations: Following IEEE standards, NFPA codes, and local regulations.

-

Thorough investigation of incidents: Conducting root cause analysis to identify and address contributing factors.

To minimize downtime and hazards following an incident, utilities often rely on power transformer health checks to inform repairs and replacement planning.