Voltage Sag

By R.W. Hurst, Editor

Power Quality Analysis Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

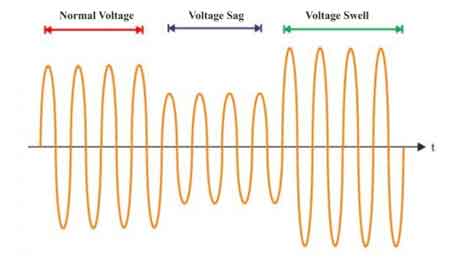

Voltage sag is a temporary drop in RMS voltage levels in electrical systems, usually caused by faults, motor startups, or load switching. This can lead to flickering lights, equipment malfunction, and power quality issues in industrial and commercial facilities.

What is a Voltage Sag?

A voltage sag is a short-duration reduction in electrical voltage (V) that can affect equipment performance and reliability.

✅ Caused by faults or motor startups

✅ Impacts industrial and commercial systems

✅ Key concern in power quality management

Overview and Significance

Voltage sag is one of the most common power quality disturbances, responsible for more than 60% of equipment malfunctions and process interruptions in industrial systems. Even a sag lasting just a few cycles can disrupt automation and cause costly downtime. Understanding its causes, classification, and mitigation is essential for maintaining stable power quality and reliable operation in commercial and industrial environments.

Causes and Influencing Factors

Voltage sags occur when the RMS voltage drops below 90% of nominal for durations between 0.5 cycles and one minute. They often result from short circuits, motor inrush currents, transformer energization, or abrupt load changes. The severity of a sag depends on fault impedance, source impedance, network configuration, and the distance from the fault to the load. Poor electrical grounding or unbalanced systems can worsen sag propagation through the distribution network.

To understand how power quality affects voltage stability, it’s essential to examine how sags, swells, and harmonics interact within industrial and commercial electrical systems.

Comparison of Common Power Quality Disturbances

| Disturbance Type | Typical Duration | Voltage Magnitude | Main Effects |

|---|---|---|---|

| Voltage Sag (Undervoltage) | 0.5 cycles to 1 minute | 10–90% of nominal | Equipment resets, flicker, process interruption |

| Voltage Dip | <0.5 seconds | <10% drop | Minor flicker, negligible system impact |

| Brownout | Minutes to hours | 70–90% of nominal | Dimmed lighting, motor overheating |

| Voltage Interruption | >1 cycle to several minutes | 0 V (complete loss) | Total shutdown, data loss, production stop |

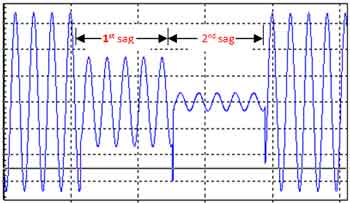

Classification and Duration

According to IEEE Std 1159 and IEC 61000-4-30, voltage sags are classified by duration:

-

Instantaneous: 0.5 to 30 cycles

-

Momentary: 30 cycles to 3 seconds

-

Temporary: 3 seconds to 1 minute

The retained V ratio is expressed as:

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Vr = V_event / V_nom

For example, a sag to 70% of nominal V equals Vr = 0.7 pu (per unit). IEEE Std 1564 introduces standardized sag severity indices that quantify voltage sag performance based on depth, duration, and frequency of occurrence.

Effects on Equipment

Voltage sags can cause computers, PLCs, and motor drives to malfunction or shut down entirely. Large motors may draw excessive current during undervoltage, leading to overheating and torque loss. Over time, repeated sag events can degrade insulation and shorten equipment lifespan. Because voltage sag directly impacts power efficiency, engineers often calculate apparent power to evaluate performance under fluctuating load conditions. Maintaining a proper power factor controller is one of the most effective ways to reduce sags and improve system reliability.

Mitigation and Compensation

Preventing voltage sags requires a combination of proper system design and active mitigation. In addition to UPS systems and regulators, modern solutions include:

-

Dynamic Voltage Restorers (DVRs): Inject compensating V during sags.

-

Active Power Filters: Balance reactive load and correct harmonic distortion.

-

Solid-State Transfer Switches (SSTS): Instantly transfer load to a healthy feeder.

-

Automatic Power Factor Controllers: Adjust reactive compensation in real time.

Facilities that experience repeated sags may benefit from automatic power factor controller systems, which dynamically adjust reactive load balance to stabilize voltage levels.

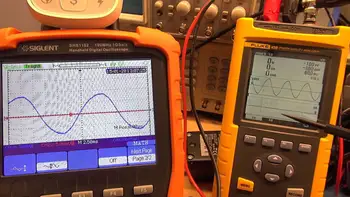

Detection, Monitoring, and Control

Using tools like a power quality analyzer allows maintenance professionals to detect voltage sags, harmonics, and flicker before failures occur. Modern analyzers apply algorithms such as the Clarke transform to identify transients and voltage dips per IEEE 1564 and IEC 61000-4-30. For those troubleshooting chronic power quality issues, our guide on power quality troubleshooting explains diagnostic methods and correction strategies that can help prevent voltage sags.

Relation to Other Power Quality Problems

Voltage sag often coincides with other phenomena such as flicker, swell, transient, and interruption. A sag combined with harmonic distortion can amplify current stress on motors and transformers, impacting stability and long-term reliability.

Frequently Asked Questions

Can voltage sag damage motors and equipment?

While most short sags do not cause permanent damage, repeated or deep sags can shorten the lifespan of motors, drives, and control systems by stressing insulation and causing cumulative thermal fatigue over time.

What is the difference between voltage sag and voltage dip?

“Voltage sag” is the term used in IEEE and North American standards, while “voltage dip” is its IEC equivalent. Both describe the same event, but dip typically applies to shorter or shallower reductions under 10% of nominal V.

How can voltage sags be prevented?

Prevention depends on system design. Installing regulation equipment, isolating sensitive loads, and using sag-tolerant components rated for IEC 61000-4-11 compliance are effective strategies to minimize operational impact.

How long can a voltage sag last?

A voltage sag can last from half a cycle to a full minute depending on network impedance and the fault’s proximity to the load. Shorter sags often recover naturally, while longer ones usually indicate feeder or transformer faults.

How are voltage sags detected and measured?

Modern power quality analyzers record waveform deviations using RMS sampling and classify sag events under IEEE 1564 and IEC 61000-4-30 criteria, enabling precise trend analysis and compliance reporting for utilities and large facilities.

Voltage sag, sometimes called a voltage dip or undervoltage event, remains one of the most critical challenges in maintaining reliable power systems. Through proper electrical grounding, advanced monitoring, and mitigation technologies, facilities can reduce downtime, extend equipment life, and sustain consistent power quality performance across industrial and commercial operations.

Related Articles