Two B.C. Hydro employees die in chopper crash

By Toronto Star

NFPA 70b Training - Electrical Maintenance

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

The pedestrian was walking along a residential street when the chopper suddenly dropped out of the sky and onto the pavement, exploding in a fireball and leaving a trail of flames and wreckage as it skidded for several metres along the street.

"There was a pedestrian walking on the street across from me," said Elmer Bautz, who saw the crash from his front window.

"I don't think he even knew what hit him. It actually touched the pedestrian and I think that's when it decapitated (him)."

The Transportation Safety Board confirmed the four deaths – the pilot, two passengers in the helicopter and the pedestrian – and said the aircraft was a Bell 206 Jet Ranger hired by B.C. Hydro.

Bautz said he had seen the small blue-and-white helicopter flying above his neighbourhood before, and it was flying low above the houses for several minutes yesterday without any problems.

But he said something seemed amiss just seconds before the helicopter came crashing down.

"My friend and I, we could tell there was something wrong because he was kind of fluttering and sputtering.... I kind of thought there was trouble but it happened so bloody quick," Bautz said.

"He came down at about a 45-degree angle.... He came down pretty fast. It was tremendously loud."

Bautz said several people living nearby rushed to the scene to help. They tried in vain to pull people from the wreckage, he said, and took off their shirts and jackets and tried to put out the fire on the pedestrian's body, but were unable to save the unidentified man.

RCMP confirmed the helicopter was operated by Bighorn Helicopters Inc., based in Cranbrook, and was being flown by a senior pilot.

The pedestrian who was killed was Isaiah Otieno, a visiting college student from Kenya.

Area resident Richard Fairchild was on the phone when the helicopter buzzed by.

It was flying so low the sound drowned out the person on the other end of the line, he said.

Fairchild watched as the aircraft made its final pass, flying over some trees, then suddenly dropping to the ground.

"It looked like he was trying to land or something, but there was no control," Fairchild said.

He said the fire was out by mid-afternoon, and burnt helicopter parts were scattered across the road.

Mary Fiorentino lives about two blocks from the crash site, where the wreckage was lying on the road.

"The houses are right there. Fortunately, it didn't hit any homes or cars parked on the street parked close to it," Fiorentino said.

Transportation Safety Board investigators were dispatched to Cranbrook, a small city of about 18,000 people in southeastern B.C., to look into the crash, said board spokesperson Bill Yearwood.

"Of course they will be trying to see first if there was any catastrophic failure in the aircraft that we might need to look and see if there's other similar aircraft at risk," he said.

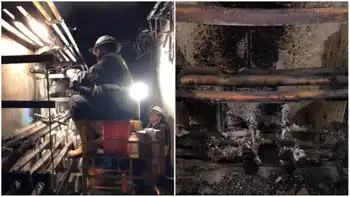

B.C. Hydro chief executive Bob Elton said the employees in the chopper were on a routine line patrol.

Bighorn Helicopters has been involved in two other board investigations over the past 10 years – one in Alberta and another near Cranbrook. Neither incident involved fatalities.

The Bell JetRanger involved in the crash is a model that's been manufactured since the early 1960s, a longtime workhorse in the helicopter business. It can carry a pilot and up to four passengers.