Three Phase Transformer in Power Distribution Systems

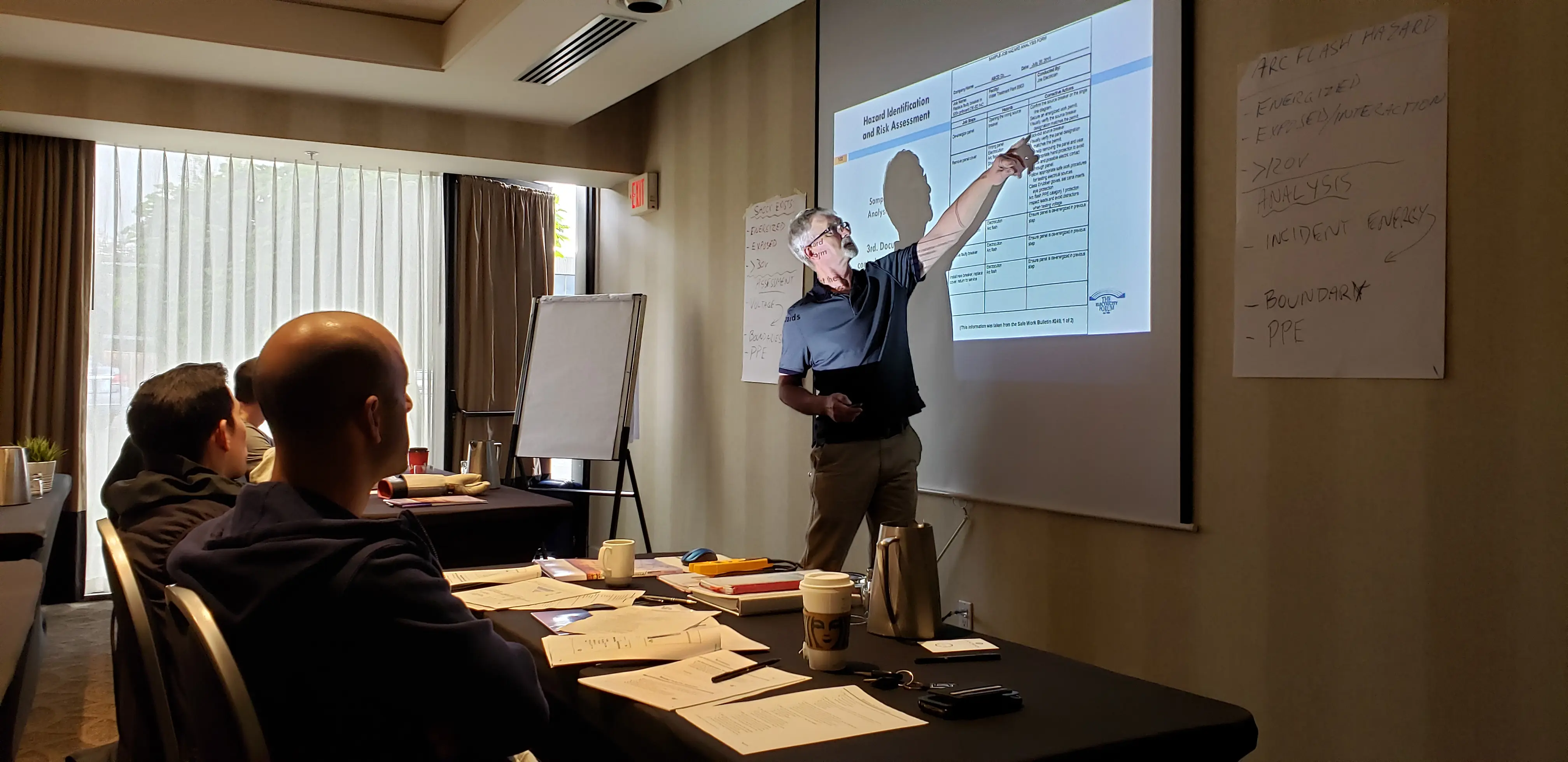

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Three phase transformer enables efficient power transmission, step-up/step-down voltage conversion, and reliable distribution in grids, featuring delta-wye connections, balanced loads, voltage regulation, low losses, and high efficiency for industrial, commercial, and utility applications.

What Is a Three Phase Transformer?

A magnetic device that converts three-phase AC voltages, stepping up or down for efficient, balanced power distribution.

✅ Delta-wye, delta-delta, and wye-wye connection options

✅ Provides step-up/step-down voltage with tight regulation

✅ Suited for industrial, commercial, and utility power systems

A three phase transformer is a critical component in power distribution, especially in utility transformers. It is designed to efficiently step up or step down electrical voltages within three-phase systems, which are widely used in commercial, industrial, and residential power applications. Unlike single-phase equipment, three phase equipment offers more stable power delivery, increased efficiency, and reduced operational costs. They play a key role in ensuring that electrical energy is distributed reliably and effectively over long distances, which is crucial for utilities that supply power to large regions. Understanding the importance and functionality of three-phase equipment is essential for optimizing power systems and improving the overall efficiency of electrical networks. For a broader overview of roles and design principles, see this resource on three phase transformers for context across utility applications.

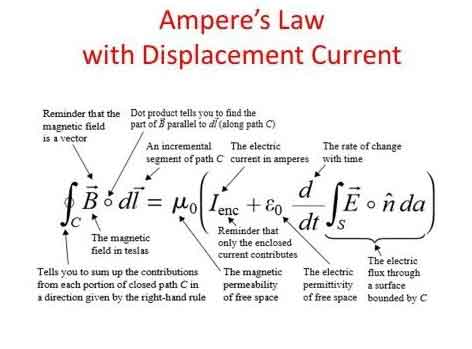

Winding Configurations

A three phase transformer's core is its ability to manage phase voltages through different winding configurations. The primary and secondary windings can be arranged in delta or star formations, with each setup offering unique benefits. In a delta-connected system, the windings form a closed-loop triangle, which supports balanced line-to-line voltage and allows the system to handle unbalanced loads effectively. Delta configurations are particularly advantageous in industrial settings where stability and efficiency are paramount. Conversely, in a star connection, each winding is connected to a common neutral point, enabling phase shift adjustments and voltage stepping, which are essential for high voltage transmission and power distribution applications. Engineers often consult detailed guides on three phase transformer connections to validate phasor relationships and grounding practices.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Power Distribution and Efficiency

One of the primary advantages of a three-phase equipment is its efficiency in power distribution. The equipment power capacity is significantly higher compared to a bank of single-phase equipment due to the shared iron core, which reduces core losses. Additionally, a three phase system ensures a more balanced load distribution, minimizing energy losses and improving the performance of electrical equipment. Whether used in manufacturing plants, commercial complexes, or renewable energy integration, these equipment are indispensable in maintaining stable and efficient power transmission.A device can be designed with a connection transformer configuration or as a bank of separate single-phase units, allowing flexibility in systems that require both single-phase power and a single-phase supply for specific loads. For comparison, fundamentals of a single phase transformer clarify why three phase designs achieve smoother power delivery.

Selection Criteria

Selecting the right type of equipment for a given application requires careful consideration of several factors. The ratings of the primary and secondary sides, including kVA capacity and voltage levels, must align with the system's requirements. The choice between copper and aluminum phase equipment windings is another crucial aspect; while copper provides better conductivity and mechanical strength, aluminum offers a cost-effective alternative with a lighter weight. Additionally, cooling methods such as air natural (AN) and oil natural air forced (ONAF) play a vital role in maintaining operational efficiency and preventing overheating. A concise primer on power transformer fundamentals can help align material choices and cooling methods with performance targets.

Winding Design and Application

Three phase transformer windings must be meticulously designed to accommodate various operational demands. Whether utilizing delta or star configurations, the arrangement of the windings determines the voltage transformation and current flow between the primary and secondary windings. This flexibility makes devices ideal for both step-up and step-down applications, with the star-delta configuration commonly used in substation equipment to lower high voltage levels for distribution, while the delta-star setup is employed for stepping up generator voltage for transmission. When ratings approach transmission scale, guidance on the role of a power transformer helps in choosing suitable insulation levels and vector groups.

Maintenance and Reliability

Maintenance plays a crucial role in ensuring the longevity and reliability of equipment. Routine inspections help detect signs of overheating, insulation degradation, and mechanical wear. For oil-filled equipment, periodic oil analysis is necessary to assess the quality and integrity of the insulating fluid, preventing moisture ingress and contamination. Additionally, thermal imaging technology is widely used to identify hotspots in the iron core and windings connected to critical components, allowing for early detection of potential failures. Best practices for an oil filled distribution transformer also translate to larger units, particularly regarding sampling intervals and moisture control.

Industrial and Renewable Energy Applications

The versatility of equipment extends beyond traditional power distribution. In industrial applications, they provide stable voltage levels to heavy machinery, ensuring consistent performance and reduced downtime. They are also integral to renewable energy systems, where they facilitate the efficient connection of wind and solar farms to the electrical grid. By managing phase shifts and ensuring seamless voltage transformation, this equipment supports the growing demand for sustainable energy solutions. In grid tie projects, selecting the proper electrical power distribution transformer ensures compliance with interconnection codes and reactive power support.

Frequently Asked Questions

What is the difference between a delta and star configuration in a three phase transformer?

In a three phase transformer, the configuration of the windings—delta or star (wye)—determines how the equipment operates and influences its voltage levels and phase relationships. In a delta configuration, the windings are arranged in a triangular pattern, where each phase is connected to two other phases. This connection results in higher line-to-line voltages, making it suitable for applications that require robust power and load balancing. On the other hand, the star configuration connects the windings in a Y-shape, with a common point (neutral) at the center. This configuration provides phase voltages that are lower than the line-to-line voltage, making it ideal for low-voltage applications like residential power distribution. The choice between delta or star configuration depends on the specific voltage requirements and the type of electrical load being supplied.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

How does a three phase transformer improve efficiency compared to single-phase equipment?

A three phase transformer offers significant efficiency improvements over single-phase equipment due to its ability to deliver continuous power with less fluctuation. In a three-phase system, power is supplied through three separate phases, reducing the likelihood of voltage dips and delivering a more stable and reliable power supply. Unlike single-phase equipment, which requires three separate units to achieve the same output, a device consolidates the functionality into one unit, reducing the overall size, cost, and weight. Moreover, the equipment uses its copper and iron core materials more efficiently, allowing for better load management and higher power density, which results in fewer losses and greater overall efficiency in power transmission.

What are the key applications of three phase transformers in industrial and commercial settings?

Three phase transformers are essential in a wide range of industrial and commercial applications. In industrial settings, they are primarily used to power large motors, machinery, and equipment that require a constant, reliable supply of electrical energy. They are also used in manufacturing plants, refineries, and large-scale production systems where heavy machinery demands high power. In commercial settings, three phase transformer helps in supplying electricity to office buildings, shopping malls, and large retail stores, ensuring that the electrical system runs smoothly and efficiently. Additionally, they play a critical role in power distribution systems, where they are used to step up or down voltage levels to suit the needs of different regions or sectors, ensuring that electricity is distributed reliably over long distances.

What factors should be considered when selecting the core type for a three phase transformer?

When selecting the core type for a device, several factors must be considered, including efficiency, load requirements, and physical space. Core-type equipment features a magnetic core around which the windings are placed. This configuration is often simpler and more cost-effective, especially for lower power ratings. They are suitable for applications where space is not a critical issue and where the equipment is not required to handle very high loads. Shell-type equipment, on the other hand, has a core that surrounds the windings, offering better support for high-current applications. These equipment provide greater mechanical strength, reduce core losses, and are more efficient for high-load or high-voltage applications. Choosing the right core type depends on the equipment’s specific application, efficiency needs, and space limitations.

How do the primary and secondary windings of a three phase transformer impact voltage regulation?

The primary and secondary windings of a device are critical in determining its performance and voltage regulation. The primary windings are connected to the input side, where electrical power enters the equipment. The secondary windings are connected to the output side, where power is supplied to the load. The ratio of turns between the primary and secondary windings determines the voltage levels that the equipment will produce. Properly configured windings ensure that the three phase transformer steps up or steps down voltage efficiently to meet the specific needs of the electrical system. Voltage regulation is also influenced by the quality of the windings and their materials; well-designed windings help minimize losses and ensure stable voltage output, even under varying load conditions. Additionally, maintaining balanced and correctly connected windings is crucial for ensuring that the equipment operates without overheating or suffering from poor efficiency.

A three-phase transformer is a vital component in modern electrical systems, enabling efficient power distribution and voltage regulation across industrial, commercial, and residential sectors. By using three separate phases, it provides continuous and stable power, significantly improving efficiency compared to single-phase equipment. The equipment's configuration—either delta or star—determines its voltage levels and phase relationships, making it adaptable to various applications. Additionally, the core type, whether core-type or shell-type, influences its performance, with each type offering distinct advantages based on load requirements. Three-phase transformers play a crucial role in powering large motors, machinery, and entire power distribution networks, ensuring reliable electricity delivery over long distances. Their design, including the primary and secondary windings, ensures optimal performance, supporting both high and low-voltage requirements across diverse industries.