Overcurrent Relay Protection

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

An overcurrent relay is a protective device that detects excessive current flow and triggers circuit breakers to prevent damage. Commonly used in power systems, it safeguards equipment from faults, short circuits, and overload conditions by monitoring current levels and operating thresholds.

What is an Overcurrent Relay?

An overcurrent relay plays a pivotal role in safeguarding electrical systems from the detrimental effects of excessive current flow.

✅ Detects and responds to excessive current levels.

✅ Protects electrical systems from faults and overloads.

✅ Works with circuit breakers for reliable power system safety.

This essential protection device detects abnormal current levels and initiates corrective action to prevent damage. Its primary objective is to ensure the continuity and stability of power supply systems in the power generation, transmission, and distribution industries. Overcurrent protection is achieved through a combination of intelligent sensing, precise time characteristics, and efficient operation, all of which contribute to the reliability of the electrical network. Understanding electrical protection systems is essential for preventing equipment damage and ensuring safe power distribution.

Substation Relay Protection Training

Request a Free Training Quotation

The functionality of an overcurrent relay revolves around the concept of current sensing and response. The function is activated when the current flowing through an electrical system surpasses a pre-determined threshold. By using time delay mechanisms, protection ensures that transient surges, such as those caused by switching operations or short-term inrush currents, do not trigger an unnecessary shutdown. The delay allows the system to distinguish between temporary fluctuations and genuine faults. This strategic approach prevents unnecessary interruptions while still offering robust overcurrent protection. Modern protective relays use advanced technologies to monitor fault conditions and coordinate with circuit breakers.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Diverse Types, Tailored Protection

Different types of overcurrent relay are employed to address specific protection needs. The instantaneous overcurrent relay, for example, responds immediately when the current exceeds a set threshold without any intentional time delay. This type trips the circuit breaker as soon as a fault is detected, making it ideal for severe short-circuit scenarios. On the other hand, an inverse time overcurrent relay employs a delay that is inversely proportional to the magnitude of the overcurrent. Higher currents result in shorter operating times, ensuring a faster response to more severe faults. Another variant, the inverse definite minimum time relay, combines features of both instantaneous and inverse time, offering a minimum time delay regardless of the current magnitude. Choosing the right circuit protection devices is vital for maintaining electrical reliability and minimizing downtime.

Comparison of Overcurrent Relay Types and Key Features

| Overcurrent Relay Type | Operating Principle | Key Advantages | Common Applications |

|---|---|---|---|

| Instantaneous Overcurrent | Trips immediately when current exceeds set value | Fast response, simple design | Short-circuit protection, motors |

| Definite Time Overcurrent | Trips after a fixed time delay | Adjustable delay, reliable coordination | Feeder and transformer protection |

| Inverse Time Overcurrent | Trip time inversely proportional to current | Better fault discrimination, selective protection | Distribution networks, transmission lines |

| Directional Overcurrent | Considers current direction and magnitude | Prevents false trips, improved selectivity | Parallel lines, ring networks |

| Numerical Overcurrent | Microprocessor-based with multiple settings | High accuracy, event logging, remote control | Modern power systems, smart grids |

The Intricate Mechanism

Certain types of overcurrent relays have extremely inverse time characteristics, and extreme inverse responses are crucial in managing complex electrical environments. These time characteristics provide greater flexibility in differentiating between fault conditions and transient disturbances. By incorporating extremely inverse time logic, the device is better equipped to coordinate with other protection devices, such as fuses and downstream protective devices, to achieve selective tripping. This coordination is essential in large interconnected power grids where multiple overcurrent relays must work in harmony.

A series of well-defined principles underpin operation. The sensing element of an overcurrent relay detects current fluctuations and activates a response mechanism. The operating time is carefully calibrated to ensure the protective device trips the circuit breaker at optimal times. This precision is achieved through the use of protection devices that incorporate advanced electronics and programmable logic. The result is a system that minimizes downtime and enhances system reliability.

Applications Across Industries

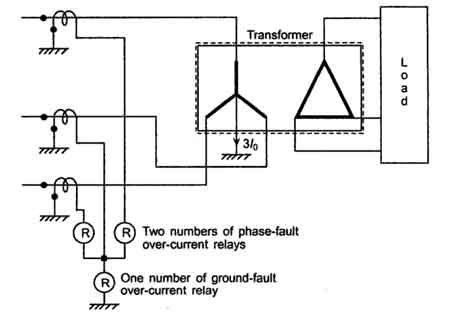

Applications of overcurrent relays extend across various industrial and commercial sectors. These protective devices protect critical equipment from overloads and short circuits in power generation plants. Power transmission networks prevent cascading failures by isolating faulted segments of the grid. Similarly, in distribution systems, they safeguard transformers, switchgear, and feeder circuits. The versatility of the overcurrent relay allows it to be deployed in diverse environments, ensuring the continuous operation of vital infrastructure. Proper power transformer protection ensures that critical equipment is shielded from overloads and internal faults.

The Imperative of Maintenance and Testing

Regular maintenance and testing of an overcurrent relay is indispensable to maintain its effectiveness. Periodic testing verifies the accuracy of the trip settings and ensures its ability to detect and respond to faults. Maintenance includes inspecting the device's physical condition, cleaning its components, and updating its firmware when necessary. Neglecting these practices can result in malfunction, leading to unplanned outages or equipment damage.

Effective testing procedures involve subjecting the overcurrent relay to simulated fault conditions. This process assesses its operating time, verifies the accuracy of its time delay, and ensures its ability to trip the circuit breaker as intended. By conducting routine maintenance and testing, operators can confirm that the protection system is ready to respond to any potential fault, thereby reinforcing the overall stability of the electrical system.

Frequently Asked Questions

What are the 3 types of overcurrent?

Overcurrent, a condition where the current flowing through a circuit exceeds its rated value, can manifest in three primary forms:

-

Short Circuit: This occurs when a low-resistance path is created between two points in a circuit, resulting in a sudden and significant increase in current.

-

Ground Fault: This happens when a portion of the circuit comes into contact with the ground, creating an unintended path for current to flow.

-

Overload: This arises when a circuit is subjected to a continuous current that exceeds its rated capacity for an extended period.

What is the difference between an overload relay and an overcurrent relay?

While both overload and overcurrent relays are designed to protect electrical systems from excessive current, they differ in their primary functions and response characteristics.

Test Your Knowledge About Electrical Protection!

Think you know Electrical Protection? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

-

Overload Relay: Specifically designed to protect against overload conditions where the current exceeds the rated value for an extended period. They typically have a delayed response to allow for temporary overloads, such as motor starting currents.

-

Overcurrent Relay: A more general-purpose overcurrent relay that protects against overload and short-circuit conditions. They are more sensitive and can respond quickly to sudden increases in current.

What is the difference between 50 and 51 overcurrent relay?

In the numerical system used to classify the protective device, 50 and 51 relays are commonly used for overcurrent protection:

-

50 Relay: This type is primarily used for instantaneous overcurrent protection. It responds very quickly to high-magnitude fault currents, such as those caused by short circuits.

-

51 Relay: This device provides time-delayed overcurrent protection. It has a characteristic curve that defines the time it takes for the overcurrent relay to trip as a function of the magnitude of the fault current. This enables selective coordination with other protective devices within the system.

By understanding these distinctions, engineers can effectively select and apply an overcurrent relay to safeguard electrical systems from various fault conditions. A thorough short circuit analysis helps engineers evaluate system safety and select the right protective devices.

An overcurrent relay is an indispensable protection device that ensures electrical systems' safety and reliability. Their ability to sense current fluctuations, apply time delay logic, and precisely operate circuit breakers makes them vital to modern power systems. Different types—such as instantaneous, inverse time, and inverse definite minimum time relays—offer tailored protection for various operational scenarios. Incorporating extreme inverse and extremely inverse time characteristics further enhances system coordination. Routine maintenance and testing ensure the long-term reliability of these devices, preventing costly damage and ensuring uninterrupted power delivery. Through their seamless integration into power generation, transmission, and distribution networks, they uphold the safety and resilience of the global electrical infrastructure.