Measuring all those Wii devices

By Globe and Mail

CSA Z463 Electrical Maintenance -

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

My first thought was to isolate my PS3 on this little corner of the energy grid, charting its power usage as it crunched numbers for Stanford University's Folding(AT)Home project. That distributed computing program breaks up staggeringly complex calculations among thousands of computers and gaming consoles. You download the client onto your computer or PS3 and then leave it running for eight hours or more as the processors unravel folding proteins, which are key to understanding many deadly diseases and their potential cures.

(My motives, I will admit, were not completely scientific in this case: You are donating to Folding(AT)Home not just your device's time, but also the electricity it takes to power all that cogitating. And it's tax season; every bit counts with research, power conservation, and maybe, down the road, Revenue Canada.) The isolation idea didn't last long, mostly because the warm air emanating from the PS3, substantial as it was, could not heat the house on its own, and the baseboard heaters were fired up. Then a computer needed charging and the oven is electric. The experimental conditions were quickly compromised.

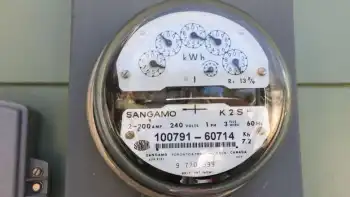

The smart meter went from one kilowatt-hour (kwh) at 3 p.m. — tracking 1,000 watts used over four days of watching an empty house — to just under 80 kwh by 9 a.m. the next day. To translate that into financial terms, consider that we pay between 5 and 15 cents for each kwh. That one night of consumption cost me about $5 (so well over $300 per month, if the juice continued to flow at that rate).

To figure out the PS3's consumption, I flipped through its manual to find that it can churn through up to 380 watts an hour. But like humans accessing 10 per cent of their brains, Sony's machine isn't using all of that current while it works. I couldn't find a consumption meter at any major retailers (funny, that), so I turned to research done by the Natural Resources Defense Council. The U.S. organization did a study in May of last year on all kinds of set-top boxes — TV receivers, DVD players and gaming consoles — and now distributes a handy guide with colourful charts.

They show console power usage climbing steadily over the years; each new generation is literally more powerful than the last. And the PS3 is right up there with mid-range PCs in terms of consumption, at around 200 watts. That means roughly five hours of folding proteins for each kwh, if the taxman ever recognizes these types of charitable efforts.

The Xbox 360 comes in at around 175 watts while playing a game or showing a movie.

The Wii, as its name suggests, uses considerably less — a stingy 20 watts, on average. But there is another thing to consider with consoles and all set-top boxes: leakage.

According to the NRDC, the Wii uses more power in idle mode than it does playing a game. All three consoles seep power even while turned off, from one watt-hour for the PS3 and 360 to almost nine watt-hours for the Wii. (The "WiiConnect24" feature downloads updates while you sleep, and it uses a pulsing-blue light, like the undercarriage of a souped-up Civic, to prove it).

With more than 20 million Wiis out there, all that electricity adds up, and not much of it comes from renewable resources yet. The best advice is to plug all of these boxes into power bars and then switch off the current when they are not in use. There are also rechargeable battery packs for their controllers, which will reduce the number of conventional batteries you need to buy and then dispose of.

This experiment does make one thing clear: The console makers need to do a lot more to help consumers cut back on their energy usage and its financial and environmental costs. The issue is barely mentioned in the documentation that ships with these devices. Stay tuned for more on that front in the near future.