California Gets $500M to Upgrade Power Grid

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

California Grid Modernization Funding will upgrade transmission and distribution, boost grid resilience, enable renewable energy integration, expand energy storage, and deploy smart grid controls statewide with over $500 million in federal infrastructure investment.

Key Points

Federal support to harden California's grid, integrate renewables, add storage, and deploy smart upgrades for reliability.

✅ Strengthens transmission and distribution for wildfire and heat resilience

✅ Integrates solar and wind with storage and advanced grid controls

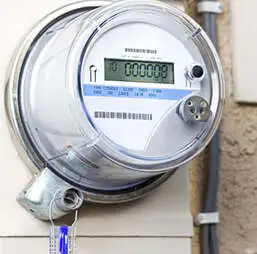

✅ Deploys smart meters, DER management, and modern cybersecurity

California has recently been awarded over $500 million in federal funds to significantly improve and modernize its power grid. This substantial investment marks a pivotal step in addressing the state’s ongoing energy challenges, enhancing grid resilience, and supporting its ambitious climate goals. The funding, announced by federal and state officials, is set to bolster California’s efforts to upgrade its electrical infrastructure, integrate renewable energy sources, and ensure a more reliable and sustainable energy system for its residents.

California's power grid has faced numerous challenges in recent years, including extreme weather events, high energy demand, and an increasing reliance on renewable energy sources. The state's electrical infrastructure has struggled to keep pace with these demands, leading to concerns about reliability, efficiency, and the capacity to handle new energy technologies. The recent federal funding is a critical component of a broader strategy to address these issues and prepare the grid for future demands.

The $500 million in federal funds is part of a larger initiative to support energy infrastructure projects across the United States, including a Washington state grant that strengthens regional infrastructure. The investment aims to modernize aging grid systems, improve energy efficiency, and enhance the integration of renewable energy sources. For California, this funding represents a significant opportunity to address several key areas of concern in its power grid.

One of the primary objectives of the funding is to enhance the resilience of the power grid. California has experienced a series of extreme weather events, including wildfires and heatwaves, driven in part by climate change impacts across the U.S., which have put considerable strain on the electrical infrastructure. The new investment will support projects designed to strengthen the grid’s ability to withstand and recover from these events. This includes upgrading infrastructure to make it more robust and less susceptible to damage from natural disasters.

Another key focus of the funding is the integration of renewable energy sources. California is a leader in the adoption of solar and wind energy, and the state has set ambitious goals for increasing its use of clean energy. However, integrating these variable energy sources into the grid presents technical challenges, including ensuring a stable and reliable power supply. The federal funds will be used to develop and deploy advanced technologies that can better manage and store renewable energy, such as battery storage systems, improving the overall efficiency and effectiveness of the grid.

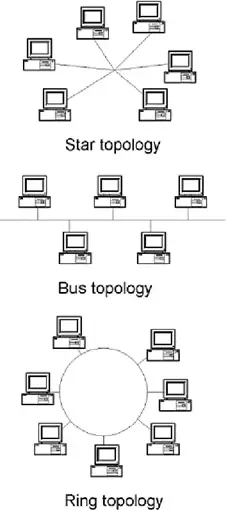

In addition to resilience and renewable integration, the funding will also support efforts to modernize grid infrastructure. This includes upgrading transmission and distribution systems, implementing smarter electricity infrastructure and smart grid technologies, and enhancing grid management and control systems. These improvements are essential for creating a more flexible and responsive power grid that can meet the evolving needs of California’s energy landscape.

The investment in grid modernization also aligns with California’s broader climate goals. The state has set targets to reduce greenhouse gas emissions and increase the use of clean energy sources as it navigates keeping the lights on during its energy transition. By improving the power grid and supporting the integration of renewable energy, California is making progress toward achieving these goals while also creating jobs and stimulating economic growth.

The allocation of federal funds comes at a crucial time for California. The state has faced significant challenges in recent years, including power outages, energy reliability issues, and increasing energy costs that make repairing California's grid especially complex today. The new funding is expected to address many of these concerns by supporting critical infrastructure improvements and ensuring that the state’s power grid can meet current and future demands.

Federal and state officials have expressed strong support for the funding and its potential impact. The investment is seen as a major step forward in creating a more resilient and sustainable energy system for California. It is also expected to serve as a model for other states facing similar challenges in modernizing their power grids and integrating renewable energy sources.

The federal funding is part of a broader push to address infrastructure needs across the country. The Biden administration has prioritized investment in energy infrastructure, including a $34 million DOE initiative supporting grid improvements, as part of its broader agenda to combat climate change and build a more sustainable economy. The funding for California’s power grid is a reflection of this commitment and an example of how federal resources can support state and local efforts to improve infrastructure and address pressing energy challenges.

In summary, California’s receipt of over $500 million in federal funds represents a significant investment in the state’s power grid. The funding will support efforts to enhance grid resilience, integrate renewable energy sources, and modernize infrastructure. As California continues to face challenges related to extreme weather, energy reliability, and climate goals, this investment will play a crucial role in building a more reliable, efficient, and sustainable energy system. The initiative also highlights the importance of federal support in addressing infrastructure needs and advancing environmental and economic goals.