Electrical Lineman Safety Equipment - Tools of the Trade

By Roger Farmer, Salisbury by Honeywell

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Lineman safety equipment includes PPE, arc-flash gear, fall protection, insulated gloves, dielectric boots, hot sticks, rescue kits, grounding sets, and harnesses, engineered to OSHA and NFPA 70E standards for high-voltage electrical work.

What Is Lineman Safety Equipment?

Lineman safety equipment is PPE and gear mitigating electrical, arc-flash, and fall hazards on overhead line work.

✅ PPE: arc-rated clothing, class-rated gloves, dielectric boots

✅ Fall arrest: full-body harness, lanyards, SRLs per ANSI Z359

✅ Live-line tools: hot sticks, grounds, phasing meters, rescue kits

When working in close proximity to exposed energized equipment or working on live electrical circuits, it’s necessary to protect not only the equipment being worked on but also the worker. Rubber insulating gloves and insulated hand tools are vital components of a successful PPE system and should be used in conjunction with each other to provide the maximum protection for the worker.

It’s common to perform a task on de-energized equipment which is locked out and tagged out while still being within the shock boundary and in close proximity to other live equipment. In this case, a worker could accidentally lose control of a tool which could then make contact with live parts. If non-insulated hand tools were being used in this scenario, in addition to a shock hazard, it is very possible that a phase over would result and an arc flash would occur. Not only could the worker be exposed to injury, but the equipment in close vicinity to this incident could sustain serious damage resulting in costly repairs, replacement, or downtime. For a deeper overview of mitigation strategies, consult the arc flash protection guidance available today.

Test Your Knowledge About Lineman Safety!

Think you know Lineman Safety? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Tools with plastic coatings or plastic handles are not suitable when “live” circuits are close to the task at hand. Employees should only consider the use of insulated tools that are marked with the official international “Suitable for live working” symbol for any type of work in close proximity to energized equipment. Complementary PPE selections are outlined in the arc flash safety gear recommendations for technicians.

The double-triangle marking is the international symbol used to identify tools as safe for energized work. This symbol must be marked on all truly insulated hand tools. These insulated hand tools have a maximum use rating of 1,000VAC and are dielectrically tested at 10,000VAC; this equates to a safety margin factor of 10. These tools should meet current ASTM F1505 and IEC 60903 standards for insulated hand tools and useful for compliance with the CSA Z462-15 standard. While insulating hand tools are designed foremost to offer shock protection for the worker, they are still considered secondary protection. Use of recognized safe work methods and other PPE should not be ignored. Understanding category thresholds is simplified in the arc flash levels of protection overview for planning.

Maintenance

Use and maintenance of insulated tools are beyond the scope of the existing standards and specifications. You should use insulated tools for their intended applications only; for example, screwdrivers should not be used to pry or chisel. You should never modify or alter a tool from its original design. For instance, cutting back the insulation on a socket for use in tight spaces could in fact expose the worker to injury. When establishing shop protocols, review the procedures to protect against electrocution to reinforce correct practices.

EF Partner Media

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

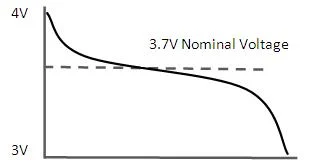

How to Read Nominal Voltage: Electrical System Engineering

Catalog

How to Read Nominal Voltage: Electrical System Engineering

Catalog

EasyPower 138-page Practical Solution Guide To Arc Flash Hazards, Third Edition

Product

EasyPower 138-page Practical Solution Guide To Arc Flash Hazards, Third Edition

Product

Pole Guard: Blocks Animal Access to Overhead Assets via Climbing the Pole

Pole Guard: Blocks Animal Access to Overhead Assets via Climbing the Pole

Because moisture, films, or other surface contaminants are conductive, insulated tools must be kept clean, dry, and free of any surface contaminants. The cleaning of insulated tools can be accomplished by using the same specialty concentrated detergent used to remove oils, grease and dirt from rubber insulated gloves. The important thing to remember when using cleaning agents is to ensure the agent does not contain any chemicals which may harm or lessen the protective value of the insulating coating. The ultimate goal is getting a residue free surface after cleaning and maintaining the insulation integrity of the tool. The same care principles used for insulating rubber gloves apply to tool insulation maintenance.

Insulated hand tools should be stored properly to minimize risk of damage to the insulation. Avoid storing in proximity to sources of heat such as radiators, furnaces, and steam pipes. Organized storage with rated barriers is also highlighted in the arc flash safety equipment guidance for facilities.

Inspection

The barrier material used to produce insulating tools is impact resistant and flame retardant and there is no re-certification process for insulated tools. Inspect all tools before use and discard tools that show any signs of visible damage. The ASTM F1505 standard allows for both single and double layer coatings. If double layer coatings are used, they should be of contrasting colours. For broader risk controls, explore advanced protection against electromagnetic exposures and electric arc strategies that complement tool inspection.

Overlapping two-colour insulated tools make inspection easier which adds to overall safety. If the under layer colour is showing through the over layer colour, the tool is no longer considered properly insulated and should be replaced. While there is no specific requirement in regards to colour other than the layers being contrasting, the industry has adopted the use of orange for the outer layer and yellow for the inner layer for all-purpose tools. Most manufacturers producing double layer insulated tools follow this colour pattern thus allowing the inner layer to be seen during the tool inspection process. Note that specialty tools made from Aluminum-Bronze and Copper-Beryllium alloys that are non-sparking and non-magnetic and are insulated, will also have a colour-contrasting double layer coating. To differentiate from all-purpose tools, these specialty tools use another colour for the outer insulating layer.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

For safety reasons other than shock and arc flash hazards, it is recommended that appropriate eye and hand protection be worn when using any type of hand tool. To fully comply with the CSA Z462-15 standard, truly insulated hand tools should be used if there is any chance that the tool will make contact with an energized source. A complete insulated tool program meeting these standards is achievable; you simply need to ensure that all your tools meet the ASTM F1505 and/or IEC 60903 standards for insulated hand tools.

Injection Molded Insulated Tools

Injection molded tools are another type of insulated tool in the market. Injection molded means they are not PVC dipped so therefore will not have a double layer coating. However, they have the same insulating properties and are also a great insulated tool