What is an Induction Motor?

By William Conklin, Associate Editor

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

An induction motor is a widely used AC machine that converts electrical energy into mechanical motion. Known for efficiency, durability, and low maintenance, it powers fans, pumps, compressors, and industrial drives across modern power systems.

What is an Induction Motor?

An induction motor is an alternating current (AC) machine where electromagnetic induction generates torque to drive mechanical loads in residential, commercial, and industrial applications.

✅ Converts electrical energy into mechanical power efficiently

✅ Reliable, durable, and requires minimal maintenance

✅ Powers fans, pumps, compressors, and industrial equipment

An induction motor is critical in numerous applications thanks to its robustness, efficiency, and low maintenance requirements. A solid understanding of its principles, types, and methods for optimizing performance can help businesses and individuals select the right device for their needs and ensure long-lasting, efficient operation. To better understand electric motors and drives, it is helpful to study induction motors as they form the backbone of many industrial and residential applications.

Induction motors, also known as AC motors, are a crucial component in operating various machinery and appliances. Due to their efficiency, robustness, and relatively simple construction have become a staple in many industrial, commercial, and domestic applications. But what is an induction motor, and how does it work? Regular electric motor maintenance is essential to preserve the durability and efficiency that make induction motors so widely used in power systems.

An induction motor operates based on the principles of electromagnetic induction and the generation of rotating magnetic fields. A rotating magnetic field is generated when an alternating current (AC) is passed through the stator winding. This field induces an electric current in the rotor, which in turn creates its own magnetic field. The interaction between these fields generates torque, causing the rotor to turn and drive the device. Learning how electric motor control works provides insight into the way an induction motor achieves precise performance in industrial environments.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Types of Induction Motors

There are two primary types of induction motors: squirrel-cage and wound-rotor device. Squirrel cage induction motors have a simple rotor construction with bars short-circuited at both ends by conducting rings, resembling a squirrel cage. These are common due to their low cost and minimal maintenance requirements. In contrast, wound rotor devices have rotor windings connected to external slip rings, which can be adjusted to control the device's performance.

Three-phase induction motors are the most widely used, offering superior power and torque characteristics compared to single-phase devices. Single-phase induction motors, however, are commonly found in smaller applications, such as household appliances. Additionally, induction motors typically require a starting mechanism to initiate rotation, as they are not self-starting. This is typically achieved by using split-phase or capacitor-start designs. A comparison of synchronous motors helps illustrate key differences in construction, operating principles, and performance.

Comparison of Induction, Synchronous, and DC Motors

| Feature | Induction | Synchronous | DC |

|---|---|---|---|

| Power Supply | AC (single-phase or three-phase) | AC (requires additional excitation for rotor) | DC (direct current supply) |

| Starting Mechanism | Self-starting (three-phase); capacitor/split-phase needed (single-phase) | Requires external starting method | Typically self-starting |

| Rotor Construction | Squirrel-cage or wound rotor | Rotor excited with DC or permanent magnets | Wound rotor with commutator and brushes |

| Speed | Runs below synchronous speed (slip present) | Runs exactly at synchronous speed | Variable with applied voltage and load |

| Efficiency & Maintenance | High efficiency, low maintenance (no brushes/commutators) | High efficiency but complex construction | Moderate efficiency; frequent brush/commutator wear |

| Applications | Fans, pumps, compressors, industrial drives | Power factor correction, high-precision machinery | Traction, cranes, elevators, variable speed equipment |

| Cost | Generally low, economical for most uses | Higher cost due to complexity | Moderate to high, depending on size and design |

What is an induction motor - Disadvantages

One of the main advantages of induction motors is their efficiency. The absence of brushes and commutators in the construction reduces friction and energy loss, increasing efficiency. Additionally, their robust construction makes induction motors highly reliable and capable of withstanding harsh environments.

Induction motors differ from other electric ones, such as DC units and synchronous devices, in several ways. For example, DC motors require a direct current supply and have brushes and commutators to enable current flow in the rotor windings. This creates friction and wear, reducing efficiency and lifespan. On the other hand, synchronous devices operate at a fixed speed, which is synchronized with the supply frequency. A review of electric motor efficiency highlights why induction motors are valued for their ability to convert electrical energy into mechanical power with minimal losses.

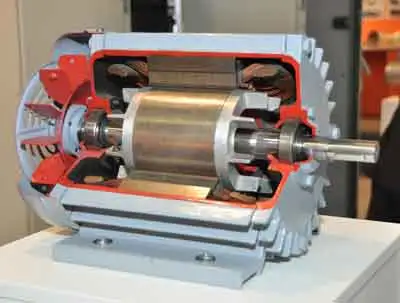

Primary Components

The primary components of an induction motor include the stator, rotor, and frame to support these elements. The stator consists of laminated iron cores with windings, while the rotor has either a squirrel cage or a wound rotor construction. The frame provides mechanical support and helps dissipate heat generated during operation.

Starting an induction motor typically involves creating a rotating magnetic field in the stator winding, which induces an electric current in the rotor. As the rotor starts to turn, its speed increases until it reaches a point slightly below the synchronous speed. This difference in speed, known as "slip," enables it to generate torque and maintain rotation. Many applications rely on variable frequency drives, which optimize the speed and torque while reducing energy consumption.

Efficiency and Performance

The efficiency and performance of induction motors can be improved through several methods. Optimizing the design, such as enhancing the quality of materials and reducing energy loss in the magnetic core, can contribute to increased efficiency. Proper maintenance, like ensuring the bearings are lubricated and the device is clean, also maximizes performance. Finally, using variable frequency drives (VFDs) enables better control over speed and torque, thereby further optimizing energy consumption. Exploring motor overload protection shows how safety devices safeguard them from excessive currents and overheating.

Thanks to their efficiency, durability, and straightforward design, induction motors are vital to many industrial and domestic applications. Understanding the working principles, types, and components can help individuals and businesses decide which one is best suited for their needs. With proper design, maintenance, and control, induction motors can offer reliable and efficient performance for various applications.

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Frequently Asked Questions

What is an Induction Motor and what is its working principle?

The working principle relies on the interaction between the rotating magnetic field generated by the stator winding and the electric current induced in the rotor. This interaction produces torque, which causes the rotor to rotate.

How does an induction motor differ from other types?

They differ from other ones, such as DC and synchronous devices, in their construction, operating principles, and performance characteristics. For instance, induction motors do not require brushes or commutators, which reduces friction and increases efficiency.

What is an Induction Motor, and what are the main components?

The main components include the stator, rotor, and frame. The stator contains windings that generate the rotating magnetic field, while the rotor has either a squirrel cage or wound rotor construction that interacts with the magnetic field. Finally, the frame provides mechanical support and facilitates heat dissipation.

What are the advantages?

Some advantages of induction motors include their efficiency, reliability, low maintenance requirements, and ability to operate under harsh conditions. Their simple construction also makes them cost-effective for many applications.

How does an induction motor start and run?

It starts and runs by creating a rotating magnetic field in the stator winding, which induces an electric current in the rotor. As the rotor starts to rotate, it reaches a speed slightly below the synchronous speed, allowing for torque generation and maintaining rotation.

What are the different types of induction motors, and how do they vary?

The two primary types of induction motors are squirrel-cage and wound-rotor devices. Squirrel cage types have a simple rotor construction with short-circuited bars, while wound rotor devices have rotor windings connected to external slip rings. Additionally, there are single-phase and three-phase induction motors, with the latter being more widely used due to their improved power and torque characteristics.

How can the efficiency and performance of an induction motor be improved?

The efficiency and performance of an induction motor can be enhanced through optimized design, proper maintenance, and the use of variable frequency drives (VFDs), which enable better control over speed and torque.

To properly answer the question: What is an Induction Motor? It is essential to understand that induction motors are the most widely used AC machines in modern industry and daily life due to their efficiency, durability, and simple design. They operate on electromagnetic induction, using a rotating magnetic field in the stator to generate torque in the rotor. Found in everything from fans and pumps to large industrial drives, induction motors require little maintenance yet deliver reliable performance under demanding conditions. Understanding their principles, types, and efficiency optimization methods allows businesses and individuals to select the right type for their needs and ensure long-term, cost-effective operation.

Related Articles