Motor Overload Protection Explained

By R.W. Hurst, Editor

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

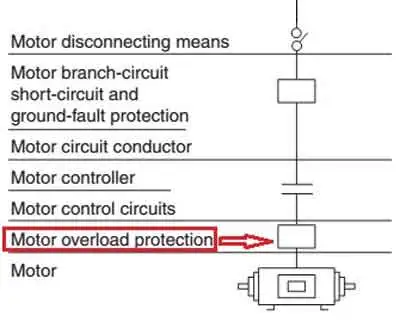

Motor overload protection prevents damage from excess current and overheating. Using overload relays, fuses, and breakers, it ensures motor safety, NEC compliance, and reliable performance in industrial and commercial systems.

What is Motor Overload Protection?

Motor overload protection is a safety mechanism that disconnects or limits power when motors draw excessive current or overheat, preventing equipment failure and fire hazards.

✅ Protects motors from overheating and electrical faults

✅ Extends the service life of equipment and systems

✅ Ensures compliance with safety codes and standards

Electric Motor Testing Training

Request a Free Training Quotation

Protecting your electric motor from excessive current and overheating is critical to maintaining its performance and efficiency. This is where safeguarding mechanisms such as overload relays, circuit protection, and branch-circuit devices come into play. Motor overload protection is part of broader overcurrent protection, which safeguards electrical systems against excessive current and fault conditions.

Motor overload protection is crucial for maintaining both performance and safety. By understanding the importance of overcurrent protection measures and the various devices available, you can make informed decisions to safeguard your equipment from potential damage or failure. When precise speed control is needed in HVAC or industrial systems, consider the role of a variable frequency drive (VFD) in optimizing AC motor performance.

The Role of Motor Overload Protection

These mechanisms are vital in defending motors from potential failure or damage. For example, when a squirrel cage motor starter is subjected to a current exceeding its capacity, it can overheat, resulting in a reduced lifespan or even complete failure. Appropriate devices, such as thermal overload relays or solid-state overload protection, detect such issues early and automatically shut down the device before permanent damage occurs. To understand how speed regulation fits into broader motor systems, see our guide on electric motor control, which covers the fundamentals of managing torque, current, and direction.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

The NEC & Sizing Rules

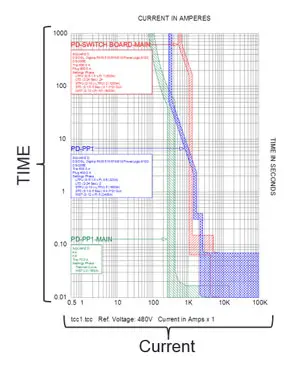

According to NEC Article 430 (Part III), overload relays must be sized and set correctly to comply with electrical safety standards:

-

Overload devices must trip at no more than 125% of full-load current (FLC) for motors with a service factor ≥ 1.15 or a temperature rise ≤ 40 °C.

-

Otherwise, relays must be set at 115% of full-load current.

Example: A motor with a nameplate FLC of 25 A and SF of 1.12 requires overload protection at ≤ 28.75 A (25 A × 115%).

For deeper insight into how motor structure affects control strategies, visit our page on electric motor design and its influence on speed and torque behavior.

Motor Overload Protection Reference Table

| Protection Type | Purpose | Key Details / NEC Guidance | Example Devices |

|---|---|---|---|

| Overload Protection | Prevents overheating from sustained excess current | NEC Article 430-32: Trip at ≤125% FLC (SF ≥1.15 or Temp Rise ≤40 °C), otherwise ≤115% | Thermal overload relay, solid-state relay, bimetallic relay |

| Inrush Current Allowance | Handles startup surges (6–8× FLC) | Must include time delay/inverse-time characteristic to avoid nuisance tripping | Magnetic starter with overload relay |

| Short-Circuit Protection | Guards against sudden surges from faults | Requires fuses or circuit breakers; not handled by overload relays | Fuses, circuit breakers |

| Ground Fault Protection | Detects leakage to ground | Prevents equipment failure and fire hazards | Ground-fault relay, breaker with GFI |

| Phase Loss Protection | Detects missing phase in supply | Protects motors from single-phasing and imbalance | Phase monitor relay |

How Thermal Mechanisms Work

One common method is thermal protection. It is designed to defend devices from excessive heat caused by high current or stalled operations. Thermal devices, such as bimetallic relays, measure temperature and disconnect power if the device exceeds a pre-determined threshold. Bimetallic relays consist of two different metals with different thermal expansion rates, which causes the relay to trip when it reaches the set temperature. If you’re just starting to explore the field, our overview of how electric motors work offers a solid foundation for understanding speed modulation principles.

Inrush vs Overload

At startup, motors often draw 6–8× their full-load current (inrush current). Overload relays must be designed with inverse-time characteristics or time delay features to prevent tripping during normal inrush while still providing protection against sustained overload.

Differences Between Overload and Short Circuit Measures

It is important to distinguish between overload and short-circuit protection.

-

Overload: A gradual rise in current and temperature due to mechanical overload or blocked ventilation.

-

Overcurrent/Short Circuit: A sudden surge caused by faults in wiring, insulation, or components, requiring fuses or circuit breakers.

Overload relays protect the motor windings from heat stress, while short-circuit protection devices (fuses, magnetic circuit breakers) prevent catastrophic faults. Both are required for complete motor branch-circuit protection. To understand how overload relays fit within a complete system of overcurrent protection devices, see our guide on fuses, breakers, and relays.

Selecting and Sizing Devices

Proper selection and sizing of devices are crucial to ensure performance and safety. Consider the full load current, voltage, and power ratings to choose the right device. Relays should be sized according to the motor nameplate rating, ensuring they trip before sustaining any damage. UL standards and NEC compliance provide additional guidance.

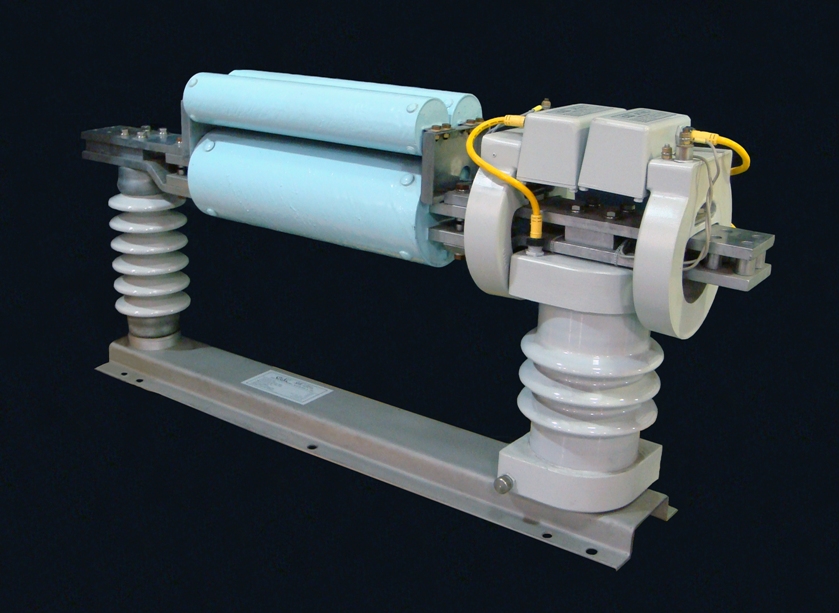

The Role of Relays in Systems

Relays are essential components of motor starter systems. They detect excessive current and initiate a shutdown to defend against damage. In addition, they are typically designed with inverse time characteristics, meaning the relay will trip faster as the current level increases. Overload relays can be electromechanical, solid-state, or bimetallic, each offering unique advantages in terms of sensitivity, accuracy, and response time.

Bimetallic Relays and Their Contribution

Bimetallic relays contribute to protection by utilizing the different thermal expansion rates of two bonded metals. When the temperature exceeds a set threshold, the bimetallic strip bends, causing the relay to trip and disconnect the power supply. This prevents overheating and ensures longevity. Enhancing system performance goes beyond speed adjustment—proper electric motor maintenance ensures long-term reliability and efficiency.

Common Types of Circuits and Applications

Several circuits are designed to address various conditions, including phase loss, ground faults, and overcurrent. Some common circuits include:

-

Overcurrent protection: Fuses, circuit breakers, or switches that disconnect power when the current exceeds a specified threshold.

-

Phase loss protection: Monitors for a missing phase in the supply voltage, which can lead to motor damage if not corrected promptly.

-

Ground fault protection: Detects leakage current between the windings and ground, preventing equipment failure or fires.

Transformers also require specific safeguards, as explained in our article on Transformer Overcurrent Protection

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Frequently Asked Questions

Can overload relays handle short-circuit conditions?

No. Overload relays are designed for sustained overloads, not instantaneous faults. Short-circuit protection must be provided by fuses or circuit breakers.

Do all motors require overload protection?

Yes, most motors must have protection in accordance with NEC requirements, with device settings based on the service factor and nameplate data.

Related Articles