What is Starting Current? Motor Efficiency Explained

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Starting current is the surge of electricity when a motor first begins turning. This inrush current, far higher than normal, influences torque, efficiency, power factor, protective devices, and overall electrical system stability during startup.

What is Starting Current?

Starting current, sometimes referred to as "inrush current," is the surge of electricity drawn by a motor during startup, usually several times higher than normal operating current.

✅ Causes mechanical stress and voltage dips

✅ Impacts circuit breakers, fuses, and protective devices

✅ Managed by soft starters or VFDs to improve reliability

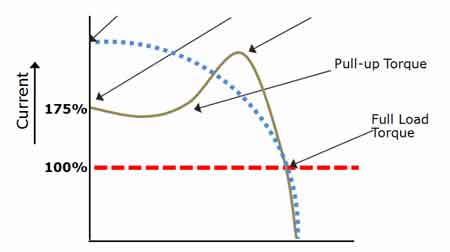

Starting current is often used interchangeably with inrush current or surge current, both of which describe the brief but intense demand placed on a system when a motor is first energized. In motor applications, this phenomenon is closely related to locked rotor current, the maximum current drawn when the rotor is stationary and torque is required to overcome inertia. At this point, the motor operates on the steepest part of the torque-speed curve, where starting torque must be high enough to accelerate the load while the electrical system sustains the temporary spike in current. Engineers and electricians rely on full-load current ratings as a baseline to estimate how many times higher the inrush current will be, since inrush current can range from four to eight times the rated load, depending on the motor size and design.

The effects of inrush current extend beyond the motor itself. High inrush can cause a voltage sag on the supply line, which may trip sensitive devices or reduce performance of other equipment sharing the same circuit. To prevent false trips and ensure reliability, protective systems are designed with a motor protection relay, which can differentiate between temporary inrush and sustained overload. By coordinating motor protection with system design, electricians can reduce the risks associated with inrush current, protect connected equipment, and ensure stable operation across industrial and commercial power systems.

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electric Motor Testing Training

Request a Free Training Quotation

Every industrial electrician must thoroughly understand this concept to ensure the safety and efficiency of electrical systems. This surge of electricity, far exceeding normal operating current, occurs in the instant an electrical device is switched on. From preventing unexpected short-circuit trips and equipment damage to implementing effective mitigation strategies, such as soft starters and star-delta configurations, this article provides a comprehensive overview of inrush current, its causes, effects, and practical solutions. Read on to gain the knowledge necessary to confidently tackle current challenges in your industrial electrical work.

Why Starting Current Is So High

Starting current, commonly referred to as high inrush current, is the initial surge of electrical energy required to power up a device such as an induction motor. This brief but intense burst occurs the moment the device is switched on and is often significantly higher than the operational current drawn during regular operation. This phenomenon is a critical consideration for engineers and electricians when designing systems that must accommodate the demands of motor starting, especially in industrial settings where electric motors play a pivotal role.

One of the key reasons the inrush current is higher than the running current is the low initial impedance of devices like motor windings. At the moment of activation, motors face the challenge of overcoming inertia while simultaneously creating the magnetic fields necessary for operation. This lack of back electromotive force (EMF), which usually opposes and reduces the flow of energy during regular operation, means the motor draws a large amount of energy from the system. In devices such as power converters, the charging of internal capacitors can also contribute to this surge, amplifying the demand placed on the system. High inrush current can reduce efficiency if not properly managed, which is directly related to electric motor efficiency strategies aimed at minimizing losses and enhancing performance.

Typical Values and Calculation

Starting current is commonly 5 to 8 times the full-load current (FLC) for small induction motors (1–5 HP). For larger machines (20–100 HP), the multiplier may be closer to 4 to 6 times FLC, as design and efficiency reduce the relative inrush.

A general formula often used is:

Starting Current (Is) = Locked Rotor Current (ILR) ≈ Full-Load Current (IFL) × k

Where k is typically between 4 and 8, depending on motor size and type.

Example:

A 10 kW induction motor with a full-load current of 60 A may have an inrush current of:

Is = 60 A × 6 = 360 A.

Using a soft starter, this can often be reduced to ~150 A, cutting voltage sag from 8% to 2%.

Motor Types and How They Differ

Different motor types exhibit distinct behaviour at startup, and understanding these differences enables electricians and engineers to select the appropriate protective devices and mitigation strategies. The magnitude of inrush current, duration of the surge, and overall impact on the system depend heavily on motor design.

-

Induction Motors: Typically 5–8× full-load current at startup, due to lack of EMF and inertia load.

-

Synchronous Motors: May have even higher surges without starting assistance, requiring external starters.

-

DC Motors: The inrush current depends on the armature's resistance and is often controlled with series resistors.

-

Universal Motors: High inrush but short duration, common in appliances.

Inrush current challenges also influence electric motor design, where winding configurations and rotor construction determine locked rotor current levels.

Terminology Clarified

Starting current is often confused with other electrical terms. Distinguishing between these related concepts facilitates the accurate analysis of motor performance and the design of effective systems. Each has a specific meaning in motor theory and practical applications.

-

Locked Rotor Current: Current drawn when the rotor is not moving (worst-case startup condition).

-

Locked Rotor Torque: Torque available at that same condition, critical for load acceleration.

-

Starting Torque vs Running Torque: Startup torque must overcome inertia; running torque maintains motion.

-

Surge Current / Inrush Current: Alternative terms for the same initial high current.

-

Startup Current Curve: Graph showing peak current at switch-on, decaying toward running current as EMF builds.

Preventing failures caused by repeated inrush is a crucial part of effective electric motor maintenance, which helps extend equipment life while reducing unplanned downtime.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Effects on Electrical Systems

through the electrical system, causing protective devices to trip, power quality issues, or premature equipment aging. Understanding these effects ensures better design and maintenance practices.

-

Circuit breakers and fuses may trip under the sudden load, causing unnecessary interruptions in power supply.

-

Voltage drops / sags are common when the motor draws more than the system can momentarily provide. Sensitive equipment connected to the same line may malfunction.

-

Thermal stress: Repeated surges heat up motor windings and insulation, leading to premature failure.

-

Harmonics and ripple effects: Fast switching and frequent restarts can increase distortion, affecting nearby devices.

Mitigation Strategies

Although inrush current is unavoidable, there are proven methods to reduce its negative effects. Choosing the right strategy depends on motor size, load characteristics, and cost considerations. Each option offers trade-offs between performance, protection, and expense.

-

Soft starters: Gradually increase voltage, reducing surge and mechanical shock.

-

Star-delta starters: Begin with a star connection to limit draw, then switch to delta for full load.

-

Variable frequency drives (VFDs): Provide precise control over voltage and frequency, reducing inrush current to 125–150% of rated current.

-

Motor protection relays: Monitor inrush and trip settings to prevent false faults.

Cost vs benefit:

-

VFDs are more expensive but provide the best control and energy savings. Modern solutions like VFDs are powerful tools for reducing inrush, and learning how does a VFD work explains why they are preferred in critical applications.

-

The star-delta configuration is cheaper but less effective for high-inertia loads.

-

Soft starters strike a balance between cost and performance for most industrial motors.

Because protective devices must react to large surges, knowledge of electric motor control is crucial for striking a balance between safety and operational reliability during startup.

Standards and Regulations

-

Global and national standards provide guidance on acceptable levels of inrush current and the application of protective devices. Compliance not only ensures safety but also reduces the risk of equipment damage and downtime due to improper system design.

-

NEMA (National Electrical Manufacturers Association): Defines locked rotor current codes for motors.

-

IEC standards (IEC 60034): Provide guidance on allowable inrush current ratios.

-

NEC / NFPA 70: Require protective devices to be sized for motor inrush without nuisance tripping.

-

CSA standards in Canada: Mirror IEC guidance with national adaptations.

Compliance ensures that protective devices, such as circuit breakers and fuses, handle line inrush without premature operation.

-

Practical Examples

Real-world applications demonstrate how starting current can disrupt systems and how mitigation strategies lead to measurable improvements. These examples, drawn from industrial, commercial, and residential settings, show both the risks of unmanaged inrush and the benefits of proper control.

-

Industrial Pump Station: A 10 kW induction motor with 60 A FLC produced 360 A inrush current. This resulted in an 8% voltage dip on the local bus. After installing a soft starter, the peak was reduced to 150 A, and the sag dropped to 2%.

-

HVAC Compressors: Inrush surges often trip undersized breakers; VFD retrofits allow smoother startup, lowering stress on both motors and building power systems.

-

Household Appliances: Refrigerators and air conditioners draw high surge currents briefly, but modern designs often integrate inrush limiters.

Since starting current is directly tied to locked rotor behavior, comparing synchronous motors and induction motors highlights the different ways each motor type manages initial torque and inrush.

Checklist

In essence, starting current is the initial surge of electricity that flows through an electrical device when it's first turned on. This surge, often significantly higher than normal operating current, occurs due to the low initial impedance of motor windings. While essential for getting devices running, high inrush current can cause voltage dips, trip circuit breakers, and damage equipment. Understanding this phenomenon and implementing mitigation strategies such as soft starters, star-delta starting, or VFDs are crucial for ensuring safe and efficient operation.

Checklist for managing starting current:

-

Calculate the expected inrush using the full-load current and the locked rotor ratio.

-

Compare the starting torque vs the running torque requirements of the load.

-

Verify that protective devices are sized to prevent nuisance trips during inrush.

-

Evaluate mitigation strategies (soft starter, VFD, star-delta).

-

Ensure compliance with NEMA, IEC, and NEC standards.

-

Monitor startup duration and acceleration time to avoid overheating.

Related Articles