How Does an Electric Motor Work?

By R.W. Hurst, Editor

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

An electric motor works by converting electrical energy into mechanical power through electromagnetism, producing rotation, torque, and speed control that drive equipment and machinery in industrial, commercial, and institutional power systems.

How Does an Electric Motor Work?

An electric motor converts electrical energy into mechanical energy, making our lives easier and more efficient. An electric motor:

✅ Converts electrical energy into mechanical motion

✅ Uses electromagnetism to create torque and rotation

✅ Powers appliances, vehicles, and industrial equipment

Let's explore the fundamental principles behind this device, discuss its key components, and address some common questions about its operation and applications.

Electric Motor Testing Training

Request a Free Training Quotation

Working Principle of Electric Motors

The working principle of an AC or DC electric motor relies on electromagnetic principles. When a current passes through a wire, it creates a magnetic field around it. This magnetic field interacts with other magnetic fields, producing a force that generates motion. In a motor, this force is harnessed to create rotational motion, driving the moving part of the motor, known as the rotor. To learn more about how motors function in modern facilities, see our detailed guide on electric motors and drives.

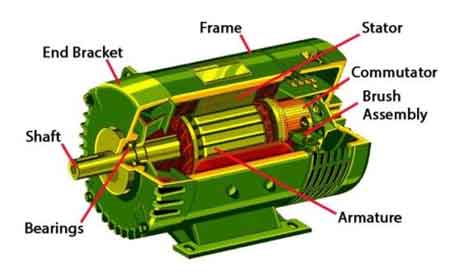

Main Components

The main components of a motor include the stator, rotor, magnetic field, current, brushes, and commutator. The stator is the stationary part of the motor, usually made of magnetic materials or wound with wire coils. It provides a stable magnetic field that interacts with the rotor's magnetic field, creating motion. The rotor is the rotating part of the motor, also made of magnetic materials or wound with wire coils. As the rotor turns, it converts the electrical energy from the power source into mechanical energy. Understanding control systems is essential for optimizing performance, and our overview of electric motor control covers the basics and advanced applications. When designing systems for industrial or commercial facilities, our article on electric motor design explains how construction choices impact performance, efficiency, and durability.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Magnetic Fields and Motion

Magnetic fields generate motion in AC motors by interacting with the current flowing through the motor's windings. When current flows through a coil, it produces a magnetic field that interacts with the stator's magnetic field. This interaction creates a force that pushes the rotor to rotate. As the rotor turns, the magnetic field changes, continuously generating a force that maintains the rotation. Facilities that rely on HVAC equipment can benefit from advanced variable frequency drive HVAC applications, which improve comfort while lowering operating costs.

Types of Electric Motors

There are various types of motors, each with distinct characteristics and specific applications:

-

AC induction motors – robust, efficient, and widely used in industry and household appliances.

-

Permanent magnet motors – compact, reliable, and highly efficient, found in EVs, robotics, and automation.

-

Brushed DC motors – simple and inexpensive, common in tools and small appliances.

Each motor type has a unique torque–speed curve and efficiency profile, making them suitable for different industrial, commercial, and institutional needs. To understand the differences in performance between motor types, visit our resource on what is a synchronous motor, which highlights its role in precision-driven applications.

Efficiency and Losses

Motors are efficient machines, but several forms of energy loss occur during operation:

-

Copper losses – resistance heating in the windings.

-

Iron losses – eddy currents and hysteresis in the motor core.

-

Mechanical losses – bearing friction and windage.

-

Stray load losses – leakage flux and minor construction imperfections.

Typical efficiencies vary by design:

-

AC induction motors: 85–95%

-

Permanent magnet motors: 92–98%

-

Brushed DC motors: 75–85%

Even a 2–3% efficiency improvement translates into major cost savings in industrial and institutional systems. Regular inspection and servicing can reduce energy waste, as explained in our article on efficiency opportunities through motor maintenance.

Motor Control and Variable Speed Drives

Modern facilities often use variable frequency drives (VFDs) or variable speed drives (VSDs) to adjust voltage and frequency. This enables precise control of torque and speed, enhances part-load efficiency, reduces mechanical wear, and achieves energy savings of up to 30% in pumps, fans, and conveyors. Variable frequency drives are a proven way to cut energy costs, and you can explore their role in detail in our section on VFD drives.

Material Innovations

Advances in materials have boosted efficiency and reliability. High-performance steels reduce core losses, rare-earth magnets improve torque density, and ferrite composites are emerging as sustainable alternatives. Hairpin windings increase copper fill and torque output, while advanced insulation resists thermal breakdown, extending motor life.

Thermal Management

Heat is a major challenge in motor design. Cooling methods range from simple air cooling with fans to liquid cooling systems in high-power applications, to direct cooling methods where a fluid removes heat directly from the windings. Effective thermal management prevents insulation failure, ensuring reliable operation under heavy industrial loads.

Commutators and Brushes

Commutators and brushes transfer current to the rotor in DC motors. The commutator directs current through the windings, while brushes maintain continuous contact, sliding as the rotor turns to sustain motion. Though effective, this design requires regular inspection and maintenance.

Industry Standards and Regulations

Motors must meet international standards to ensure efficiency and safety. IEC efficiency classes range from IE1 (standard) to IE4 (super premium), and many regions now require IE3 or higher for new installations. NEMA sets similar benchmarks in North America, ensuring motors deliver reliable performance while reducing long-term energy costs. For engineers selecting equipment in industrial environments, our resource on what is an induction motor explains why this type remains one of the most widely used.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Applications

Motors are used in nearly every sector of society:

-

Industrial – pumps, compressors, conveyors, and heavy machinery.

-

Commercial – HVAC systems, elevators, escalators, and refrigeration.

-

Institutional – hospitals, schools, and critical infrastructure.

-

Transportation – EVs, trains, aircraft systems, and ships.

From small appliances to massive industrial installations, motors remain essential to modern life.

Future Trends and Challenges

The future will be shaped by sustainability, smart technologies, and regulation. Manufacturers are reducing reliance on rare-earth magnets, developing recyclable designs, and improving lifecycle efficiency. Smart motors with IoT sensors enable predictive maintenance. Growing EV adoption drives demand for compact, high-efficiency motors, while renewable energy expands their role in wind, hydro, and solar systems. Governments worldwide continue to raise minimum efficiency standards, pushing the industry toward cleaner and smarter designs.

Frequently Asked Questions

What is the working principle of an electric motor?

They convert electrical energy into mechanical energy through the interaction of magnetic fields and electric currents.

What are the main components?

The main components include the stator, rotor, magnetic field, current, brushes, and commutator.

How do magnetic fields generate motion?

Magnetic fields generate motion by interacting with the current flowing through the motor's windings, creating a force that pushes the rotor to rotate.

What are the different types?

Some common types include AC induction motors, permanent magnet motors, and brushed DC motors.

How do commutators and brushes work?

Commutators and brushes transfer current to the rotor, with the commutator directing current through the motor windings and the brushes maintaining the flow of current as the rotor turns.

How can efficiency be improved?

Efficiency can be improved by optimizing motor design, using high-quality materials, implementing advanced control techniques, and maintaining the motor properly.

What are the common applications of electric motors?

They are utilized in various applications, including household appliances, power tools, EVs, and industrial equipment.

By understanding how motors work and their importance in our lives, we can better appreciate the engineering and innovation that goes into these devices. With ongoing advancements in the field, we can look forward to even more efficient and environmentally friendly motor technologies that will continue to shape our world.

Related Articles