Transformer Nameplate Explained

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

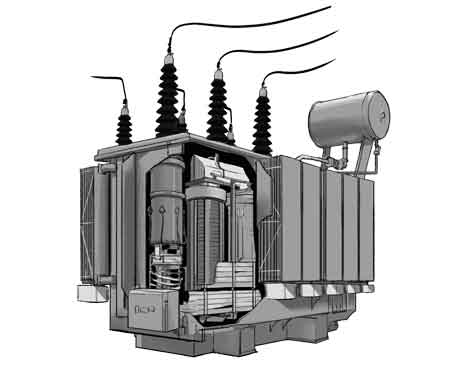

A transformer nameplate provides vital identification, rating data, and electrical specifications, ensuring safe operation, maintenance accuracy, and compliance with power distribution standards in utility, industrial, and commercial electrical systems.

What is a Transformer Nameplate?

A transformer nameplate is the manufacturer’s label that displays essential details, such as voltage, current, kVA rating, impedance, and cooling class, for safe and efficient operation.

✅ Identifies electrical ratings and specifications

✅ Supports safety, compliance, and maintenance

✅ Guides installation, testing, and operation

The transformer nameplate serves as a vital resource for electrical professionals, offering essential information about the operational characteristics and specifications. Understanding the details on this nameplate is critical for ensuring the proper selection, installation, and maintenance of the equipment within an electrical system. This comprehensive guide illuminates the key elements, highlighting their contributions to safe and efficient operation. A utility transformer nameplate provides vital ratings and specifications that ensure safe operation in large-scale distribution systems.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Key Information Encoded on a Transformer Nameplate

One of the most prominent details found is the voltage rating. This information specifies the primary and secondary voltages that the unit can accommodate. These ratings are crucial for ensuring compatibility with the connected electrical system. The voltage rating ensures that the equipment can handle the required load without overloading or creating an electrical network mismatch. For instance, the transformer nameplate will clearly list the voltage for both the primary and secondary windings, providing guidance for proper system integration. Engineers often reference the 3-phase transformer nameplate to confirm voltage ratios, kVA ratings, and impedance values before installation.

Another critical aspect is the kva rating, which stands for kilovolt-amperes. This value indicates the power capacity and is a fundamental factor in determining its load-handling capability. Electrical engineers rely on the kva rating to ensure it can support the intended load without risk of failure. This rating is also essential for planning the unit’s role in an electrical system, particularly when managing energy distribution across various loads.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Comparison Table: Common Transformer Nameplate Data

| Data Item | Typical Values Example | Purpose/Use |

|---|---|---|

| Voltage Rating | 13.8 kV / 480 V | Defines input/output operating range |

| kVA Rating | 1500 kVA | Indicates power handling capacity |

| Frequency | 50/60 Hz | Matches system grid requirements |

| Impedance | 5–8% | Helps with fault current calculations |

| Cooling Class | ONAN / ONAF | Identifies cooling method |

| Temperature Rise | 55°C or 65°C | Ensures safe thermal operation |

| Connection Type | Delta / Wye | Guides system integration |

Information on transformer components such as the core, windings, and insulation is often encoded on the nameplate for maintenance planning.

Phase Relationships

The phase relationships listed on the transformer nameplate are another essential component. This information identifies the type of phase transformer in use—whether it is single-phase or three-phase. The number of phases has a direct impact on the application, as three-phase transformers are typically used in industrial and commercial environments, while single-phase transformers are more common in residential and small commercial settings. The phase relationships also influence the overall design and complexity of the electrical system.

In addition to phase relationships, the vector diagram on the nameplate illustrates the phase displacement between the primary and secondary windings. This graphical representation is critical for engineers to understand how the voltages are oriented relative to one another. Proper alignment of phase angles is crucial to prevent phase mismatches that could lead to short circuits or equipment damage. The vector diagram is particularly valuable during system troubleshooting and testing.

The nameplate also provides specifications regarding the conductor material used in the windings. Copper and aluminum are the most common materials, and each has distinct properties affecting efficiency, cost, and thermal performance. Copper windings generally offer superior conductivity and efficiency, but they are more expensive. Aluminum, on the other hand, is lighter and more cost-effective, but it has lower conductivity. Knowing the conductor material helps maintenance teams understand the system's efficiency and potential losses.

Understanding Transformer Design and Cooling

Information on the cooling method is another key feature of the transformer nameplate. Cooling is essential for maintaining safe operating temperatures, especially when high loads are present. Forced air cooling and oil-immersed cooling are two prevalent methods. Forced air cooling involves the use of fans to dissipate heat, while oil-immersed cooling relies on a fluid medium to transfer heat away from the windings. The nameplate indicates which cooling system is used, ensuring that proper cooling mechanisms are maintained to avoid overheating and extend the life. The construction of transformer details found on the nameplate guide professionals in understanding winding arrangements and insulation requirements.

Temperature rise is also prominently displayed on the nameplate, as it directly relates to the thermal limits. This parameter represents the maximum allowable temperature increase in the winding insulation under full load conditions. Excessive temperature rise can degrade the insulation and reduce the equipment's lifespan. By following the temperature rise specifications, operators can prevent overheating, which is a common cause of failure. Nameplate data is essential for selecting the right distribution transformer to match system load and service conditions.

Role of the Tapchanger

A vital element of design is the tap changer, which enables the adjustment of the voltage output. The tap changer’s presence on the transformer nameplate allows technicians to identify the range of voltage adjustments available. By altering the tap settings, operators can fine-tune the voltage to match specific load requirements. This feature is especially useful in fluctuating load conditions where precise voltage regulation is necessary to maintain system stability. The substation transformer's nameplate lists voltage classes and cooling methods, which are critical for grid reliability.

The oil volume indicated on the nameplate refers to the quantity of insulating oil that is present. This oil serves as both an insulator and a cooling medium, ensuring that the internal components remain protected from electrical faults and thermal stress. Monitoring the oil volume is crucial for maintenance, as insufficient oil levels can lead to overheating or reduced insulation performance. Understanding transformer insulation values on the nameplate ensures compliance with thermal limits and long-term equipment safety.

Serial Number

The serial number is another key identifier found on the transformer nameplate. It acts as a unique reference for tracking the manufacturing details, maintenance history, and warranty information. This identifier is crucial for asset management, allowing facility operators to log maintenance records, schedule inspections, and track operational performance. In the event of a failure, the serial number enables quick access to manufacturer support and replacement parts.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The presence of short circuits as a design consideration is also addressed on the nameplate. While the unit itself is built to withstand short circuits to a certain extent, the nameplate’s information helps operators understand the device’s short circuit capacity. This knowledge is crucial during system design and protection coordination, as it ensures the transformer can endure high current surges caused by faults without incurring damage.

By understanding the wealth of information, electrical engineers and maintenance professionals can ensure the safe, efficient, and reliable operation of systems. From voltage rating and kva rating to cooling methods and tap changers, each detail plays a pivotal role in optimizing system performance and mitigating the risk of failure. The label serves as a guide for equipment selection, maintenance, and operational decisions, ensuring that every aspect of the design is clearly understood and properly managed.

Frequently Asked Questions

What is on a Transformer Nameplate?

It is a small metal plate affixed to the body. It provides crucial information about the capabilities and operational parameters. This information is essential for engineers, technicians, and anyone involved in the installation, maintenance, and operation.

5 Key Specifications on a Transformer Nameplate

-

Voltage Rating: This specifies the primary and secondary voltages at which the unit is designed to operate.

-

KVA Rating: This indicates the capacity to handle electrical power.

-

Frequency Rating: This specifies the frequency of the power supply, typically 50 or 60 Hz.

-

Connection Group: This indicates the phase shift between the primary and secondary windings.

-

Cooling Method: This specifies the cooling technique used, such as oil-immersed, air-cooled, or forced-air cooled.

H1 and H2 on a Transformer

H1 and H2 are typically markings on the transformer's terminals. They indicate the phase shift between the primary and secondary windings. The specific phase shift depends on the connection group.

How to Read the Numbers?

To read the numbers, refer to the nameplate. The numbers usually represent:

-

Voltage Ratings: These are typically given in kilovolts (kV) or volts (V).

-

KVA Rating: This is the apparent power rating

-

Current Ratings: These are the maximum currents that can flow through the primary and secondary windings.

-

Impedance: This is a measure of the internal resistance and reactance.

-

Tap Settings: These indicate different voltage levels that can be selected using a tap changer.

Note: The specific information on a transformer nameplate can vary depending on the manufacturer and the type. It's always best to consult the manufacturer's documentation or a qualified electrician for accurate interpretation.

Related Articles