Understanding When to Use Metal Conduit vs PVC

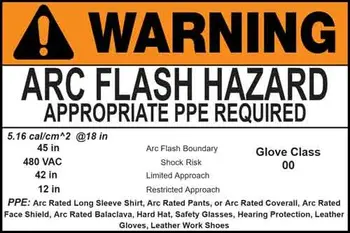

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

When to Use Metal Conduit vs PVC? Compare EMT/rigid for grounding, EMI shielding, impact strength, and heat; choose PVC for corrosion resistance, wet locations, direct burial, UV exposure, and chemical environments per NEC.

When to Use Metal Conduit vs PVC?

Use metal for grounding, EMI shielding, and impact; use PVC for corrosion resistance, wet or buried runs, and chemicals.

✅ Metal: grounding, EMI shielding, high impact/heat, indoor industrial

✅ PVC: corrosion-proof, wet locations, direct burial, chemical plants

✅ Follow NEC: fitting types, bonding, derating, temperature limits

Did you know that a seemingly simple choice like conduit material can make or break your electrical installation? Selecting the right conduit, whether metal or PVC, is crucial for ensuring safety, longevity, and code compliance in any electrical project. While both materials serve the essential function of protecting and routing electrical wires, they each possess unique characteristics that make them suitable for different environments and applications. This article dives deep into the metal conduit vs PVC debate, exploring their key differences, advantages, disadvantages, and installation considerations to help you make informed decisions for your next project. For a broader understanding of how conduit selection relates to wire types, see this guide to electrical cables for planning your layout.

What are the key differences between metal conduit and PVC, and when should each be used?

Metal conduit, often made from galvanized steel, is renowned for its robust strength and ability to withstand impacts, making it the go-to choice for industrial settings, construction sites, and areas prone to physical stress. Furthermore, metal conduit provides inherent grounding capabilities, adding an extra layer of safety by providing a low-resistance path for fault currents to flow to ground. This is critical in preventing electrical shocks and equipment damage. Within the metal family, EMT (Electrical Metallic Tubing) offers a lighter-duty option that still provides reliable protection for many commercial runs.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

On the other hand, PVC conduit shines in its resistance to corrosion and moisture. This lightweight and non-conductive material is ideal for underground installations, damp locations like basements, and areas exposed to harsh chemicals. PVC's ease of installation, thanks to its flexibility and simple joining methods, makes it a favorite for DIYers and contractors alike. Understanding how materials interact with current is useful, and the basics outlined in what conducts electricity help explain why PVC’s non-conductive properties enhance certain safety strategies.

In what environments is metal conduit preferred over PVC?

Think heavy-duty! Metal conduit reigns supreme in environments where physical protection is paramount. Industrial facilities with heavy machinery, construction zones with potential for impact, and areas with high vibration all benefit from the ruggedness of metal conduit. Moreover, in hazardous locations where flammable gases or vapors may be present, metal conduit provides an added layer of protection by containing sparks or arcs that could ignite an explosion. In such high-risk settings, pairing raceways with appropriately rated equipment like metal-clad switchgear can further improve resilience and fault containment.

When is PVC conduit a better choice than metal conduit?

PVC conduit takes the lead when corrosion is a concern. Underground installations, where moisture and soil conditions can wreak havoc on metal, are prime candidates for PVC. Similarly, in areas exposed to chemicals or saltwater, PVC's resistance to corrosion ensures the longevity and integrity of the electrical system. Its lightweight nature also makes it easier to handle and install in tight spaces or overhead applications.

How does the installation process differ between metal conduit and PVC conduit?

Installing metal conduit often involves specialized tools like threading machines and conduit benders. The rigid nature of metal conduit requires careful planning and precise cuts to ensure proper alignment and secure connections. While more labor-intensive, the resulting installation is incredibly robust and durable. For installers mastering field techniques, the step-by-step guidance on how to bend conduit can reduce errors when laying out offsets and saddles.

PVC conduit, in contrast, offers a more DIY-friendly installation experience. Simple hand tools like hacksaws and PVC cutters are sufficient for cutting and shaping the conduit. Joining sections is typically done with solvent cement, creating a watertight and secure bond. PVC's flexibility also allows for easier navigation around obstacles and bends. Once raceways are in place, best practices for pulling and terminating conductors in accordance with conductor and cable installation standards help ensure long-term reliability.

What are the cost considerations when choosing between metal conduit and PVC?

PVC conduit generally enjoys a lower upfront cost compared to metal conduit. The material itself is less expensive, and the simpler installation process translates to reduced labor costs. However, the long-term cost-effectiveness depends on the specific application. In environments where corrosion is a major factor, PVC's longevity can lead to significant savings on repairs and replacements down the line. Evaluating lifecycle cost should also account for conductor selection in buried runs, and insights on copper for underground transmission can inform decisions about durability and losses over time.

The "metal conduit vs PVC" decision ultimately hinges on the specific demands of your electrical project. Metal conduit offers unparalleled strength and grounding capabilities, making it ideal for harsh and hazardous environments. PVC conduit counters with its corrosion resistance, ease of installation, and cost-effectiveness, making it suitable for underground, damp, and corrosive locations. By carefully considering the factors discussed in this article, you can confidently choose the right conduit material to ensure a safe, reliable, and code-compliant electrical installation.