OPG Small Modular Reactors advance clean energy with advanced nuclear, baseload power, renewables integration, and grid reliability; factory built, scalable, and cost effective to support Ontario energy security and net zero goals.

Key Points

Factory built nuclear units delivering reliable, low carbon power to support Ontario's grid, renewables, climate goals.

✅ Factory built modules cut costs and shorten schedules

✅ Provides baseload power to balance wind and solar

✅ Enhances grid reliability with advanced safety and waste reduction

Ontario Power Generation (OPG) is at the forefront of Canada’s energy transformation, demonstrating a robust commitment to sustainable energy solutions. One of the most promising avenues under exploration is the development of Small Modular Reactors (SMRs), as OPG broke ground on the first SMR at Darlington to launch this next phase. These innovative technologies represent a significant leap forward in the quest for reliable, clean, and cost-effective energy generation, aligning with Ontario’s ambitious climate goals and energy security needs.

Understanding Small Modular Reactors

Small Modular Reactors are advanced nuclear power plants that are designed to be smaller in size and capacity compared to traditional nuclear reactors. Typically generating up to 300 megawatts of electricity, SMRs can be constructed in factories and transported to their installation sites, offering flexibility and scalability that larger reactors do not provide. This modular approach reduces construction time and costs, making them an appealing option for meeting energy demands.

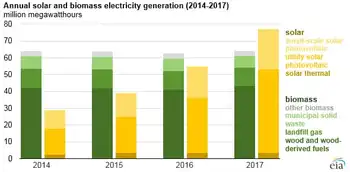

One of the key advantages of SMRs is their ability to provide baseload power—energy that is consistently available—while simultaneously supporting intermittent renewable sources like wind and solar. As Ontario continues to increase its reliance on renewables, SMRs could play a crucial role in ensuring that the energy supply remains stable and secure.

OPG’s Initiative

In its commitment to advancing clean energy technologies, OPG has been a strong advocate for the adoption of SMRs. The province of Ontario has announced plans to develop three additional small modular reactors, part of its plans for four Darlington SMRs that would further enhance the region’s energy portfolio. This initiative aligns with both provincial and federal climate objectives, and reflects a collaborative provincial push on nuclear innovation to accelerate clean energy.

The deployment of SMRs in Ontario is particularly strategic, given the province’s existing nuclear infrastructure, including the continued operation of Pickering NGS that supports grid reliability. OPG operates a significant portion of Ontario’s nuclear fleet, and leveraging this existing expertise can facilitate the integration of SMRs into the energy mix. By building on established operational frameworks, OPG can ensure that new reactors are deployed safely and efficiently.

Economic and Environmental Benefits

The introduction of SMRs is expected to bring substantial economic benefits to Ontario. The construction and operation of these reactors will create jobs, including work associated with the Pickering B refurbishment across the province, stimulate local economies, and foster innovation in nuclear technology. Additionally, SMRs have the potential to attract investment from both domestic and international stakeholders, positioning Ontario as a leader in advanced nuclear technology.

From an environmental perspective, SMRs are designed with enhanced safety features and lower waste production compared to traditional reactors, complementing life-extension measures at Pickering that bolster system reliability. They can significantly contribute to Ontario’s goal of achieving net-zero emissions by 2050. By providing a reliable source of clean energy, SMRs will help mitigate the impacts of climate change while supporting the province's transition to a sustainable energy future.

Community Engagement and Collaboration

Recognizing the importance of community acceptance and stakeholder engagement, OPG is committed to an open dialogue with local communities and Indigenous groups. This collaboration is essential to addressing concerns and ensuring that the deployment of SMRs is aligned with the values and priorities of the residents of Ontario. By fostering a transparent process, OPG aims to build trust and support for this innovative energy solution.

Moreover, the development of SMRs will involve partnerships with various stakeholders, including government agencies, research institutions, and private industry, such as the OPG-TVA partnership to advance new nuclear technology. These collaborations will not only enhance the technical aspects of SMR deployment but also ensure that Ontario can capitalize on shared expertise and resources.

Looking Ahead

As Ontario Power Generation moves forward with plans for three additional Small Modular Reactors, the province stands at a critical juncture in its energy evolution. The integration of SMRs into Ontario’s energy landscape promises a sustainable, reliable, and economically viable solution to meet growing energy demands while addressing climate change challenges.

With the support of government initiatives, community collaboration, and continued innovation in nuclear technology, Ontario is poised to become a leader in the advancement of Small Modular Reactors. The successful implementation of these projects could serve as a model for other jurisdictions seeking to transition to cleaner energy sources, highlighting the role of nuclear power in a balanced and sustainable energy future.

In conclusion, OPG's commitment to developing Small Modular Reactors not only reinforces Ontario’s energy security but also demonstrates a proactive approach to addressing the pressing challenges of climate change and environmental sustainability. The future of energy in Ontario looks promising, driven by innovation and a commitment to clean energy solutions.

Related News