Variable Frequency Drive Training - Learn Motor Controls

By R.W. Hurst, Editor

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Variable Frequency Drive Training builds competency in VFD fundamentals, AC motor control, vector control, commissioning, troubleshooting, harmonics mitigation, safety, and PLC integration for efficient drives, energy savings, and reliable industrial automation.

What Is Variable Frequency Drive Training?

Training on VFD theory, motor control, setup, safety, and troubleshooting to optimize AC drives and automation.

✅ Configure VFD parameters, I/O, and motor nameplate data

✅ Apply vector control, PID loops, and energy-saving strategies

✅ Diagnose faults, harmonics, EMI, and resonance issues

Variable frequency drives are becoming increasingly common in industrial applications. They offer a number of benefits, including increased energy efficiency, improved process control, and reduced wear and tear on equipment. As a result, there is a growing demand for VFD training. For an introductory overview, see what a VFD is to align terminology.

Visit our course page: Variable Frequency Drive Training

If you are new to the acronym, what does VFD stand for offers helpful context.

Objectives and Key Topics of Our Training Course

The primary objective of this training course is to equip participants with the knowledge and skills necessary for the proper installation, commissioning, maintenance, and troubleshooting these motor control devices. Key topics covered typically include: Additionally, this quick reference on variable frequency drives clarifies core concepts.

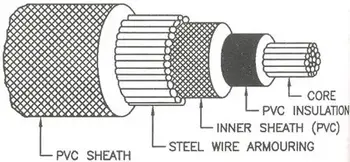

- Understanding Components and Operations: Detailed insights into the various parts and their functions.

- Installation and Commissioning: Best practices ensure optimal performance.

- Troubleshooting and Maintenance: Techniques for identifying and resolving common issues.

- Integration with Distribution Systems: How they interact with other components in the electrical distribution system.

- Energy Efficiency: Strategies for leveraging motor controls to improve energy efficiency in motor-driven applications.

To connect theory to products, explore common VFD drive architectures and their typical use cases.

Prerequisites for Enrolling in our Training Program

Before enrolling in our training course, participants should have a foundational understanding of electrical systems and motor control. Typically, this includes:

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

- Basic knowledge of AC and DC motor operations.

- Familiarity with electrical safety standards and practices.

- Previous experience or training in electrical engineering or maintenance.

These prerequisites ensure that participants can effectively grasp the advanced concepts and applications discussed in the training. For foundational operation principles, review how a VFD works to reinforce essentials.

Delivery Methods of Training

Variable frequency drive training courses are delivered through various methods to accommodate different learning preferences and schedules:

- Online Courses: These provide flexibility, allowing participants to learn at their own pace from any location. Live online sessions often include interactive elements such as Q&A sessions and hands-on virtual labs.

- In-person Training: Traditional classroom settings offer direct interaction with instructors and hands-on experience with actual equipment, at your facility.

- Hands-on Labs: Practical sessions where participants can apply theoretical knowledge to real-world scenarios, enhancing their troubleshooting and maintenance skills.

Participants who want deeper parameter setup can study VFD programming for practical configuration tips.

Certification and Qualifications

Upon completing a training course, participants typically receive a certification or qualification that signifies their proficiency in motor controls. This certification is valuable for career advancement and is often recognized by employers as evidence of specialized expertise. For instance, successful completion of our training course might earn Continuing Education Units (CEUs) or Professional Development Hours (PDHs), which contribute to professional development requirements in many industries.

Follow-up Resources and Support

Continuing support and resources are crucial for the effective application of training knowledge. Many training providers offer:

- Technical Papers and Handbooks: Comprehensive materials that cover the course content and can be used as reference guides.

- Email Mentoring: Post-training support where participants can reach out to instructors with specific questions or issues.

- Online Forums and Communities: Platforms where participants can share experiences, seek advice, and discuss new developments in technology.

In conclusion, a well-structured training course is essential for professionals seeking to enhance their knowledge and skills in handling motor control devices. Such training not only covers the theoretical aspects but also provides practical, hands-on experience. With proper training, electrical engineers, maintenance personnel, and technicians can significantly improve their ability to install, maintain, and troubleshoot motor controls, ultimately leading to more efficient and reliable electrical systems. Many professionals also encounter the term frequency converter when sourcing equipment.

For more information on variable frequency drive training, including course schedules and enrollment details, visit this page: Variable Frequency Drive Training