Current Transformer Ratio

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

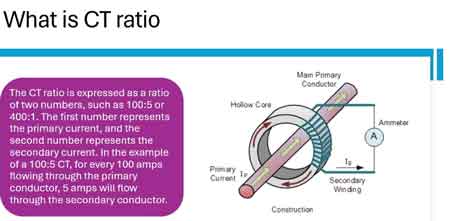

The current transformer ratio indicates how a current transformer scales high primary current to a lower secondary current. Commonly used in metering and protection, it ensures accurate measurement and safe monitoring in electrical power systems.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

What is: "current transformer ratio"

Current transformer ratio is fundamental in safely and accurately measuring electrical current in high-voltage applications.

✅ Indicates the relationship between the primary and secondary current in a CT

✅ Enables safe monitoring of high-voltage circuits by scaling current

✅ Essential for power system metering, protection, and relay coordination

To better understand the device itself, see our overview of what is a current transformer, which explains how CTs operate in high-voltage environments.

Understanding the CT Ratio

The current transformer ratio indicates the relationship between the primary and secondary amps, specifying how many primary amps correspond to a specific number of secondary amps. For example, a 300:5 CT means 300 amps on the primary side is reduced to 5 amps on the secondary.

This ratio enables electrical meters and relays—designed to handle only low currents—to interface with high-current circuits safely. By converting 100s or even 1000s of amps down to a measurable scale, CTs prevent direct exposure of equipment and personnel to dangerous current levels. For a full breakdown of transformer roles in power systems, visit our guide to electrical power transformers, which includes CTs, PTs, and isolation units.

Common CT ratios include:

-

100:5

-

200:5

-

300:5

-

400:5

-

600:5

-

1000:5

Secondary output currents are almost always 5A or 1A, depending on the instrument’s design. Learn more about instrument transformers, a category that includes current transformers and voltage transformers used for metering and protection.

Why the Ratio Matters in Electrical Systems

In power distribution systems, current transformers are everywhere—from substations to industrial motor control centers. The CT ratio selected directly affects the accuracy of measurement and the sensitivity of protective relays.

Test Your Knowledge About Electrical Transformers!

Think you know Electrical Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

A mismatch between CT ratio and the system current can result in:

-

Inaccurate readings (under- or over-representation of actual current)

-

Delayed or failed tripping by overcurrent protection devices

-

Misleading data in load profiling and energy billing

Understanding and choosing the correct ratio is essential for maintaining both safety and operational efficiency.

Current transformers play a crucial role in electrical measurement and protection. They step down high currents in primary circuits to a manageable level, ensuring that monitoring and protection equipment can safely handle the transformed current. The primary and secondary currents are key elements of this system, working together to maintain accuracy and safety. The current transformer ratio, specifically, refers to the relationship between the primary current in the transformer’s primary conductor and the output in its secondary winding. Properly selecting this ratio ensures the safety and reliability of devices such as meters, relays, and control instruments. If you're looking for a broader understanding of transformer types and applications, check out our article on different types of transformers.

How to Calculate the Current Transformer Ratio

To determine the correct ratio for a specific application, start by understanding the electrical system's needs. Typically, the ratio is calculated by dividing the primary current by the number of secondary amps the transformer produces. For instance, a 300:5 indicates that for every 300 amps passing through the primary, 5 amps are produced in the secondary winding. Ensuring that the number of turns in the secondary winding supports this relationship is essential for accurate current transformation. This understanding not only protects electrical workers but also enhances system efficiency by providing reliable readings and protection. Discover how CT ratio calculations are integrated into our current transformer simulation tool to model real-world applications.

To calculate the CT ratio:

CT Ratio = Primary Current ÷ Secondary Current

Example:

A CT with a 600:5 rating means 600 amps in the primary results in 5 amps in the secondary. The turns ratio (if 1 primary turn is assumed) is 120:1. This ratio tells us the scaling factor for translating high-voltage current into a usable signal for instruments.

If you pass the primary conductor through the CT core multiple times, you effectively reduce the CT ratio. For example, running the conductor twice through a 100:5 CT changes the effective ratio to 50:5.

This flexibility is useful when CTs with ideal ratings are unavailable or the load profile changes after installation. For high-voltage applications, see how the capacitor voltage transformer compares to current transformers in protection schemes.

CT Accuracy and Burden Ratings

CT performance is defined not just by its ratio, but also by:

-

Accuracy Class – e.g., 0.3, 0.6 for metering; C100, C200 for protection

-

Burden – the total impedance (in ohms or VA) of devices connected to the CT secondary

The Accuracy class defines how closely the secondary output matches the scaled primary input. For instance, a class 0.3 CT has a maximum error of ±0.3 % under the specified burden.

Burden includes the resistance of meter coils and lead wires. If the burden is too high, CTs may saturate, meaning they can't accurately reproduce the current waveform, which can cause false readings or relay failure.

Always select CTs with ratings appropriate to the devices and wire lengths involved.

CT Polarity and Phasing

CT terminals are marked with polarity indicators:

-

H1 / H2: Primary current terminals

-

X1 / X2: Secondary winding terminals

Correct polarity is essential for devices that depend on the direction of current, such as directional relays or power meters. The current entering H1 should leave from X1 in phase with the primary. Reversing this can cause inaccurate readings or faulty relay operation.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

CT polarity errors are common in installations and can be catastrophic in protection systems. Always double-check orientation.

CT Safety: Never Open the Secondary Under Load

This is a critical rule in electrical safety:

- Never open the CT secondary circuit while the primary is energized.

When the secondary loop is broken while current is flowing in the primary, the core has nowhere to discharge its magnetic energy. This creates dangerously high voltages across the open terminals—often thousands of volts—which can:

-

Damage insulation

-

Destroy connected equipment

-

Electrocute workers

If a CT needs to be removed or tested, always short the secondary first using a shorting block or switch.

Multi-Tap and Multi-Ratio CTs

Modern CTs often offer multiple taps on the secondary winding. These are labelled with selectable ratio options, such as:

-

100:5 / 200:5 / 400:5

-

150:5 / 300:5 / 600:5

Switching between taps allows users to adjust the CT ratio without replacing the transformer. This flexibility is valuable in facilities where loads vary or future upgrades are planned.

Multi-ratio CTs must be connected properly—unused terminals must be insulated, and selected taps must match the expected input to avoid ratio mismatch or damage.

Selecting the Right Ratio for Protection and Metering

Choosing the appropriate current transformer ratio for protection and metering involves evaluating several factors, including load requirements and system voltage. For applications requiring precise metering, a lower ratio may be sufficient, while high-voltage protection often necessitates a higher ratio to manage the elevated current levels safely. The number of secondary windings and the series transformer configuration should align with the system’s demands. For instance, a 100:5 CT might be chosen for a high-current application, allowing only five amps in the secondary while handling 100 amps in the primary. This process often involves selecting a series transformer with the correct number of turns in both primary and secondary windings. You can also explore how CTs relate to control transformers, which manage voltage regulation for control circuits in electrical systems.

Why CT Ratio Knowledge Matters

The current transformer ratio is not just a number—it's the backbone of scaling for every power monitoring and protection system. Whether you’re an electrician, engineer, or technician, understanding CT ratios helps you:

-

Prevent equipment damage

-

Ensure accurate billing

-

Protect systems from faults

-

Maintain compliance with standards

Choosing the correct ratio, validating polarity, accounting for burden, and observing safety procedures will ensure your power systems remain accurate, safe, and efficient.

Related Articles