Optimizing Equipment Maintenance with Hour Meters

Power Factor Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Optimizing Equipment Maintenance with ENM meters boosts predictive maintenance, condition monitoring, and power quality analytics, enabling IoT/SCADA integration, reliability-centered maintenance, and downtime reduction for electrical assets across industrial power systems.

What Is Optimizing Equipment Maintenance with ENM Meters?

Using ENM meters to drive predictive maintenance, power quality insights, and asset reliability in electrical systems.

✅ Real-time power quality, harmonics, and load profiling metrics

✅ Predictive maintenance via trend analytics and alarm thresholds

✅ Integrates with SCADA, CMMS, and IIoT for asset workflows

Proper equipment maintenance is crucial for maximizing uptime, extending service life, and minimizing unexpected failures. One of the most effective tools for achieving this is the hour meter—a simple yet powerful device that tracks the duration of equipment operation. By accurately logging run-time, hour meters enable maintenance teams to schedule service intervals based on actual usage rather than relying on guesswork or calendar dates. ENM Company, a leading manufacturer of counting instruments, offers a range of hour meters specifically engineered to support this process in both industrial and commercial settings. Understanding the fundamentals of power quality helps teams align maintenance with the electrical environment.

Why Hour Meters Matter for Maintenance

Instead of relying on reactive maintenance or vague schedules, hour meters enable condition-based servicing. This not only helps avoid premature part replacements but also reduces the risk of catastrophic failures caused by overuse. Maintenance activities such as oil changes, filter replacements, and system inspections can be triggered precisely when needed—based on actual run-time data. This approach improves equipment efficiency, lowers operational costs, and enhances safety. When paired with targeted power quality monitoring, hour meters add context about voltage events that can refine service intervals.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

ENM Hour Meters for Different Applications

ENM’s product line offers a variety of hour meters designed to meet specific application needs, whether for DC systems, AC-powered machinery, or vibration-based equipment.

T40 Quartz DC Hour Meter

Ideal for battery-powered or DC-powered systems, the T40 Quartz DC Hour Meter is a low-power, tamper-resistant solution that ensures precise time tracking without requiring battery backup. It is especially well-suited for vehicles, generators, and industrial machines where DC voltage is present. Its compact, sealed design ensures durability and long-term reliability. Download the T40 Datasheet here.

T50 Quartz AC Hour Meter

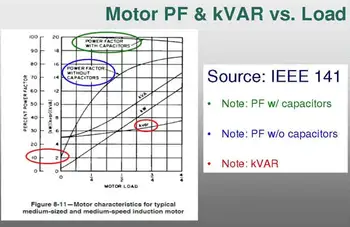

For AC-powered equipment, the T50 Quartz AC Hour Meter delivers robust performance using a quartz-crystal time base. Its high accuracy and simple panel mounting make it ideal for tracking runtime on motors, compressors, and HVAC systems. Designed for rugged use, the T50 performs reliably even in harsh electrical environments. Download the T50 Datasheet here. Facilities tracking motor loads often integrate a power factor meter alongside the T50 to correlate runtime with reactive power trends for improved efficiency.

T56E Vibration Activated LCD Hour Meter

When electrical connections are impractical or unavailable, the T56E Vibration Activated LCD Hour Meter offers an innovative solution. It detects equipment operation via vibration and features three separate time-tracking modes. With adjustable vibration sensitivity and no need for wired installation, it is perfect for portable or gas-powered equipment such as lawn mowers, construction tools, and small engines. Its LCD display is easy to read and stores data securely, even when power is removed. Download theT56E Datasheet here. For intermittent issues on small engines, referencing proven power quality troubleshooting techniques can guide root-cause analysis beyond simple runtime metrics.

Improved Efficiency and Lifecycle Management

By deploying hour meters across your equipment fleet, you gain the ability to forecast wear and tear, plan downtime strategically, and align spare parts inventory with real-world usage patterns. These devices act as silent sentinels, gathering essential data that supports predictive maintenance and improves the return on investment (ROI) of your capital equipment. Combining hour-based service data with a power quality analyzer helps identify electrical stressors that accelerate wear on critical components.

EF Partner Media

Industries That Benefit from Hour Meter Use

-

Manufacturing: Track runtime of CNC machines, presses, and conveyors. In plants with sensitive electronics, adherence to quality of electricity guidelines supports consistent output.

-

Construction: Monitor portable equipment, generators, and compactors. On sites with generator-fed systems, evaluating high resistance grounding options can reduce fault energy while maintaining service continuity.

-

Fleet Management: Service vehicles based on engine hours, not mileage.

-

HVAC: Schedule regular maintenance on fans, pumps, and air handlers.

-

Agriculture: Maintain tractors, irrigation systems, and diesel engines efficiently.

Optimizing equipment maintenance isn’t just about keeping machines running—it’s about running them smarter. ENM hour meters such as the T40, T50, and T56E give businesses the tools they need to make data-driven maintenance decisions. With reliable time-tracking across a wide range of electrical and mechanical systems, these meters provide an essential layer of operational intelligence that helps prevent downtime and improve performance.

ENM Company is a U.S.-based manufacturer specializing in electronic and electromechanical counters, hour meters, tachometers, and custom-engineered instruments. Founded in 1957, ENM has built a reputation for quality, innovation, and reliability, serving industries ranging from manufacturing and construction to agriculture and transportation. With a strong focus on precision time-tracking and monitoring solutions, ENM products are designed to enhance operational efficiency and equipment maintenance across a wide range of applications.

To learn more about these products and how they can support your maintenance goals, visit ENM Company’s official website.

For More Information

ENM Company

5617 Northwest Highway

Chicago, IL 60646-6135

Phone: 773 775-8400

Toll Free : 888 372-0465

Fax: 773 775-5968

Email: customerservice@enmco.com